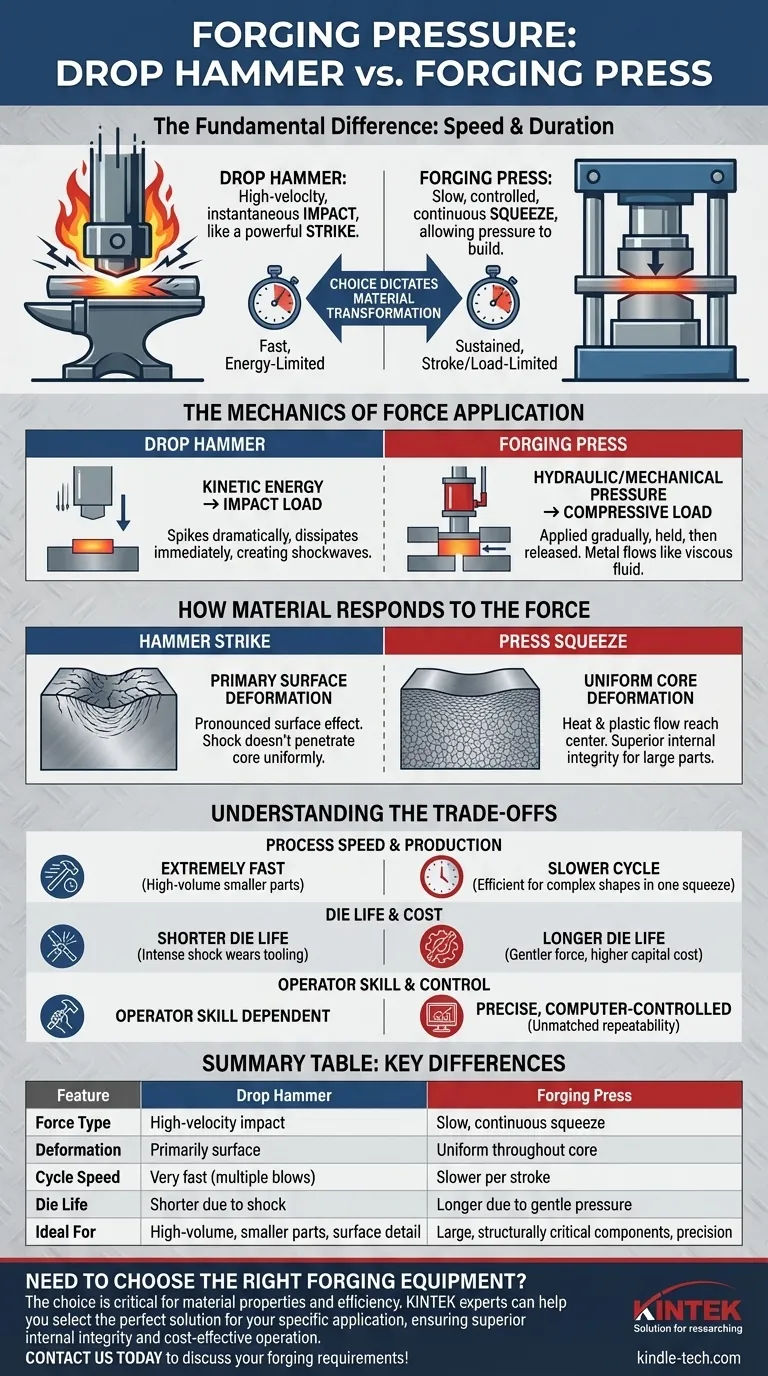

The fundamental difference lies in speed and duration. A drop hammer applies force through a high-velocity, instantaneous impact, much like a powerful strike. In contrast, a forging press applies force as a slow, controlled, and continuous squeeze, allowing the pressure to build and be sustained throughout the forming process.

Choosing between a forging hammer and a press goes beyond simply shaping metal; it dictates how the material itself is transformed. Hammers provide high-velocity impacts ideal for rapidly shaping surfaces, while presses deliver sustained pressure that deforms a material's entire volume, yielding superior internal integrity for large components.

The Mechanics of Force Application

To understand the results, you must first understand the two distinct physical principles at play. One is based on kinetic energy, and the other is based on controlled mechanical or hydraulic pressure.

Drop Hammers: The Principle of Impact

A drop hammer operates on the principle of converting potential energy into kinetic energy. A heavy ram is lifted and then dropped or accelerated onto the workpiece.

This creates an impact load—a massive amount of force delivered in a fraction of a second. The process is energy-limited; the total deformation is governed by the energy available in a single blow, determined by the ram's mass and drop height.

The force is not constant. It spikes dramatically upon contact and dissipates almost immediately, creating a powerful shockwave through the material.

Forging Presses: The Principle of Compression

A forging press uses a mechanical or hydraulic system to move a ram at a much slower, more controlled speed. It squeezes the workpiece between the dies rather than striking it.

This creates a compressive load. The force is applied gradually, held for a longer duration, and then released. This process is stroke-limited or load-limited, meaning the press is designed to deliver a specific maximum force throughout its travel.

This sustained pressure gives the metal time to flow into the die cavities, behaving more like a viscous fluid.

How Material Responds to the Force

The difference between a "strike" and a "squeeze" has profound implications for the final workpiece, affecting everything from its internal structure to its final dimensions.

Surface vs. Core Deformation

The rapid, short-duration impact of a hammer tends to cause deformation that is more pronounced on the surface of the workpiece. The shock doesn't have enough time to penetrate and deform the core of a thick section uniformly.

Conversely, the slow, sustained pressure from a press allows heat and plastic flow to reach the center of the workpiece. This results in a more thorough and uniform deformation throughout the material's entire cross-section, which is critical for large components.

Grain Structure and Final Properties

The slow squeezing action of a press kneads the material, leading to a highly uniform and refined grain structure throughout the part. This generally results in superior mechanical properties, such as toughness and fatigue resistance.

While a hammer also refines grain structure, the effect can be less uniform between the surface and the core. However, the impact action is excellent for filling intricate, sharp details on a part's surface.

Understanding the Trade-offs

Neither method is inherently superior; they are suited for different applications, and the choice involves balancing cost, speed, and final part requirements.

Process Speed and Production Rate

Hammers are extremely fast, delivering multiple blows in a short period. This makes them highly effective for high-volume production of smaller components where multiple strikes are needed to fill the die.

Presses have a slower cycle time per stroke. However, because they deform the material so completely, they can often form a complex part in a single squeeze, making them more efficient for certain geometries.

Die Life and Equipment Cost

The intense shock of an impact load is extremely hard on tooling. Dies used in hammers experience significant wear and have a shorter operational life.

The controlled compressive force of a press is much gentler on the dies, leading to longer die life and less frequent maintenance. However, large forging presses, particularly hydraulic ones, represent a significantly higher capital investment than hammers.

Operator Skill and Process Control

Traditional hammer forging often relies heavily on operator skill to judge the number and intensity of blows required.

Modern presses, especially hydraulic systems, offer precise, computer-controlled command over ram speed and pressure. This provides unmatched repeatability and process control, reducing reliance on operator judgment and ensuring consistent part quality.

Making the Right Choice for Your Application

Your decision should be guided by the final requirements of the component you are producing.

- If your primary focus is high-volume production of smaller parts with good surface detail: A drop hammer is often the more economical and faster choice.

- If your primary focus is creating large, structurally critical components with uniform internal properties: A forging press is the superior method due to its deep, controlled deformation.

- If your primary focus is precision, automation, and repeatability for complex shapes: A modern hydraulic press offers the best process control and is the clear winner.

Understanding this core distinction between impact and compression empowers you to select the process that ensures your product meets its required strength, integrity, and cost targets.

Summary Table:

| Feature | Drop Hammer | Forging Press |

|---|---|---|

| Force Type | High-velocity impact | Slow, continuous squeeze |

| Deformation | Primarily surface | Uniform throughout the core |

| Cycle Speed | Very fast (multiple blows) | Slower per stroke |

| Die Life | Shorter due to shock | Longer due to gentle pressure |

| Ideal For | High-volume, smaller parts | Large, structurally critical components |

Need to choose the right forging equipment for your lab or production line? The choice between a hammer and a press is critical for achieving the desired material properties and production efficiency. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the perfect solution for your specific application, ensuring superior internal integrity and cost-effective operation. Contact us today to discuss your forging requirements!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- Why is a laboratory hydraulic press required during the preparation of Ti3AlC2 precursor pellets?

- How does a laboratory hydraulic press contribute to the preparation of green pellets for nanostructured eutectic steel?

- What is the hydraulic forging process? Master the Art of High-Strength Metal Forming

- What is the function of a bench-top laboratory hydraulic press for XRF? Maximize Accuracy in Prosopis juliflora Analysis

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation