At its core, the Vacuum Induction Degassing Pouring (VIDP) furnace is designed for efficiency by radically minimizing the vacuum volume and enabling rapid component swaps. Instead of placing the entire melting operation inside a massive vacuum chamber, the crucible itself acts as the compact vacuum chamber, drastically cutting down on gas evacuation time and simplifying maintenance.

The fundamental advantage of the VIDP furnace is its design philosophy: the crucible is the vacuum chamber. This dramatically reduces the volume that needs to be evacuated, leading to faster pump-down times, lower energy consumption, and greater overall production speed compared to traditional chamber-type furnaces.

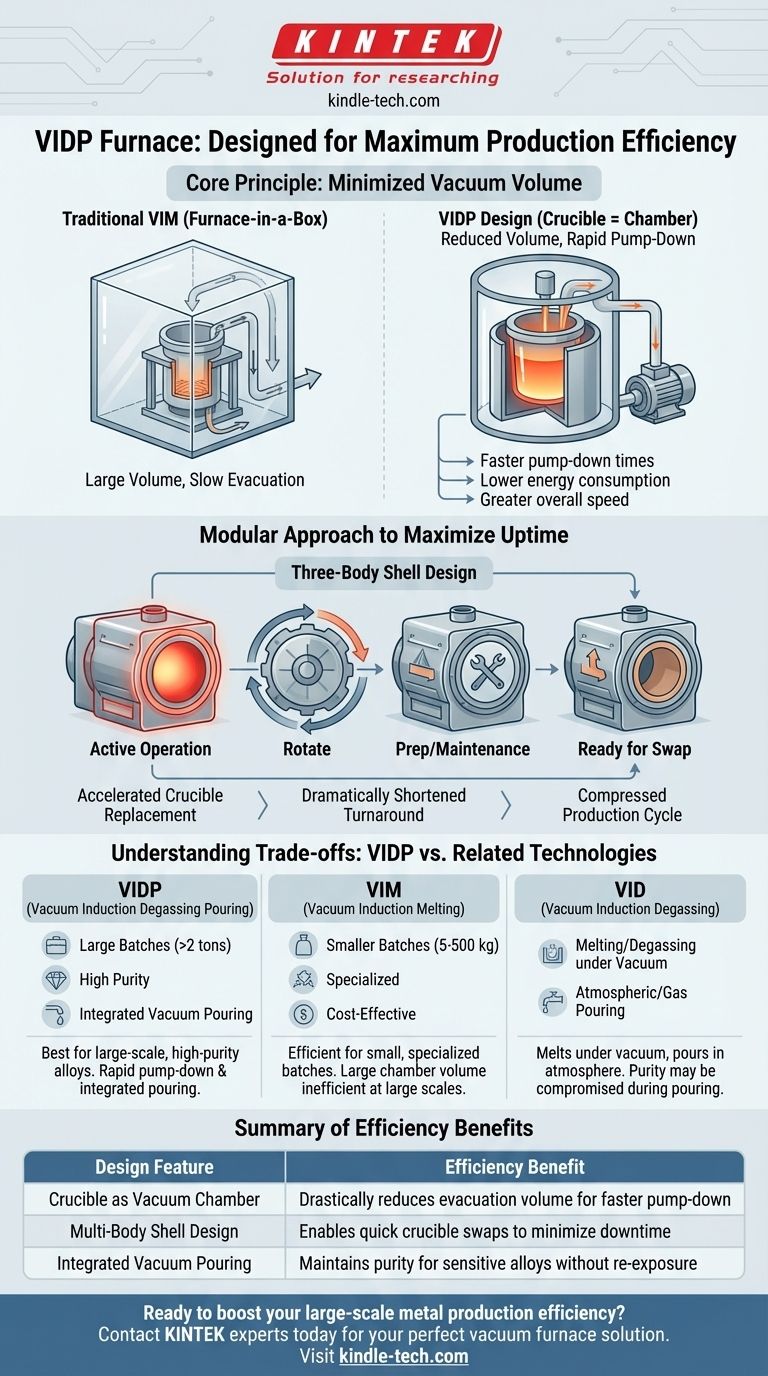

The Core Design Principle: Minimizing Vacuum Volume

The most significant efficiency gain in a VIDP furnace comes from its intelligent and compact structure. This design directly impacts multiple stages of the production process.

How the Crucible Becomes the Chamber

Unlike traditional Vacuum Induction Melting (VIM) furnaces that place a crucible inside a large vacuum vessel, the VIDP design integrates the vacuum chamber around the melting assembly itself.

Only the essential smelting and pouring components are enclosed, creating a much smaller and more efficient vacuum environment.

The Direct Impact on Pump-Down Times

A smaller chamber volume allows vacuum pumps to achieve the required low pressure much more quickly.

This shorter evacuation time directly reduces the cycle time for each batch, a critical factor for efficiency, especially in furnaces designed for larger charge weights (over 2 tons).

Reduced Leakage and Easier Maintenance

The compact design means there is less surface area for potential vacuum leaks, which simplifies leak detection and repair.

Furthermore, the smaller, more accessible interior makes essential tasks like cleaning and replacing thermocouples significantly faster and easier.

A Modular Approach to Maximize Uptime

Beyond the core vacuum design, the VIDP furnace incorporates modularity to minimize downtime between melting cycles.

The Three-Body Shell Design

To maximize operational readiness, the furnace shell is often equipped with three separate furnace bodies. This design facilitates a streamlined workflow for crucible management.

Accelerating Crucible Replacement

This multi-body configuration allows one crucible to be in operation while another is being prepared with a new lining or undergoing maintenance.

When a crucible change is needed, the prepared body can be swapped in quickly, dramatically shortening the turnaround time compared to relining a crucible in place.

Shortening the Overall Production Cycle

By nearly eliminating the time spent waiting for crucible relining and preparation, the overall production cycle is significantly compressed, leading to a direct and substantial boost in production efficiency.

Understanding the Trade-offs: VIDP vs. Related Technologies

To fully appreciate the VIDP's design, it's helpful to compare it to other vacuum furnace technologies.

VIDP vs. VIM (Vacuum Induction Melting)

Traditional VIM furnaces are excellent for smaller, highly specialized batches (typically 5-500 kg). However, their "furnace-in-a-box" design becomes inefficient at larger scales due to the massive chamber volume that must be evacuated.

The VIDP design is specifically optimized for larger melts (above 2 tons), where its rapid pump-down time provides a decisive efficiency advantage.

VIDP vs. VID (Vacuum Induction Degassing)

A standard VID furnace melts and degasses material under vacuum but then pours the molten metal into a mold in an atmospheric or protective gas environment.

The integrated "Pouring" (the "P" in VIDP) is the key differentiator. A VIDP furnace maintains the vacuum from the melting chamber through a vacuum runner and into the ingot chamber, preventing any re-exposure to atmospheric gases and ensuring the highest purity for sensitive alloys.

Making the Right Choice for Your Goal

Selecting the right furnace technology depends entirely on your specific production requirements.

- If your primary focus is producing large batches (>2 tons) of high-purity alloys: The VIDP's rapid pump-down time and integrated vacuum pouring make it the most efficient choice.

- If your primary focus is maximizing throughput and minimizing downtime: The VIDP's multi-body shell design for quick crucible replacement is a critical advantage.

- If your primary focus is smaller, specialized melts requiring vacuum integrity: A traditional VIM furnace may offer a more suitable and cost-effective solution for that scale.

By fundamentally rethinking the relationship between the crucible and the vacuum chamber, the VIDP furnace delivers a powerful and efficient solution for the large-scale production of advanced metals.

Summary Table:

| Design Feature | Efficiency Benefit |

|---|---|

| Crucible as Vacuum Chamber | Drastically reduces evacuation volume for faster pump-down |

| Multi-Body Shell Design | Enables quick crucible swaps to minimize downtime |

| Integrated Vacuum Pouring | Maintains purity for sensitive alloys without re-exposure |

Ready to boost your large-scale metal production efficiency? KINTEK specializes in advanced lab equipment like the VIDP furnace, designed for high-purity alloy production with maximum uptime. Contact our experts today to find the perfect vacuum furnace solution for your laboratory's specific needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- Can induction furnace melt iron? Unlock High-Efficiency, Clean Melting for Iron & Alloys

- What is the difference between core type furnace and coreless induction furnace? Choose the Right Tool for Your Foundry

- What is the temperature of induction heating process? Unlock Precise Control from Gentle Warming to 1800°C+

- What is the primary advantage of the vacuum environment in this type of furnace? Achieve Oxidation-Free Precision

- What is the furnace used to melt gold? Discover the Clean, Fast Induction Method

- What type of furnace do I need to melt steel? The Definitive Guide to Induction Furnaces

- How does vacuum induction melting improve nickel-base alloy properties? Boost Corrosion Resistance for Reactor Safety

- Does induction heating work on non-ferrous metals? A Guide to Efficiently Heating Copper, Aluminum & More