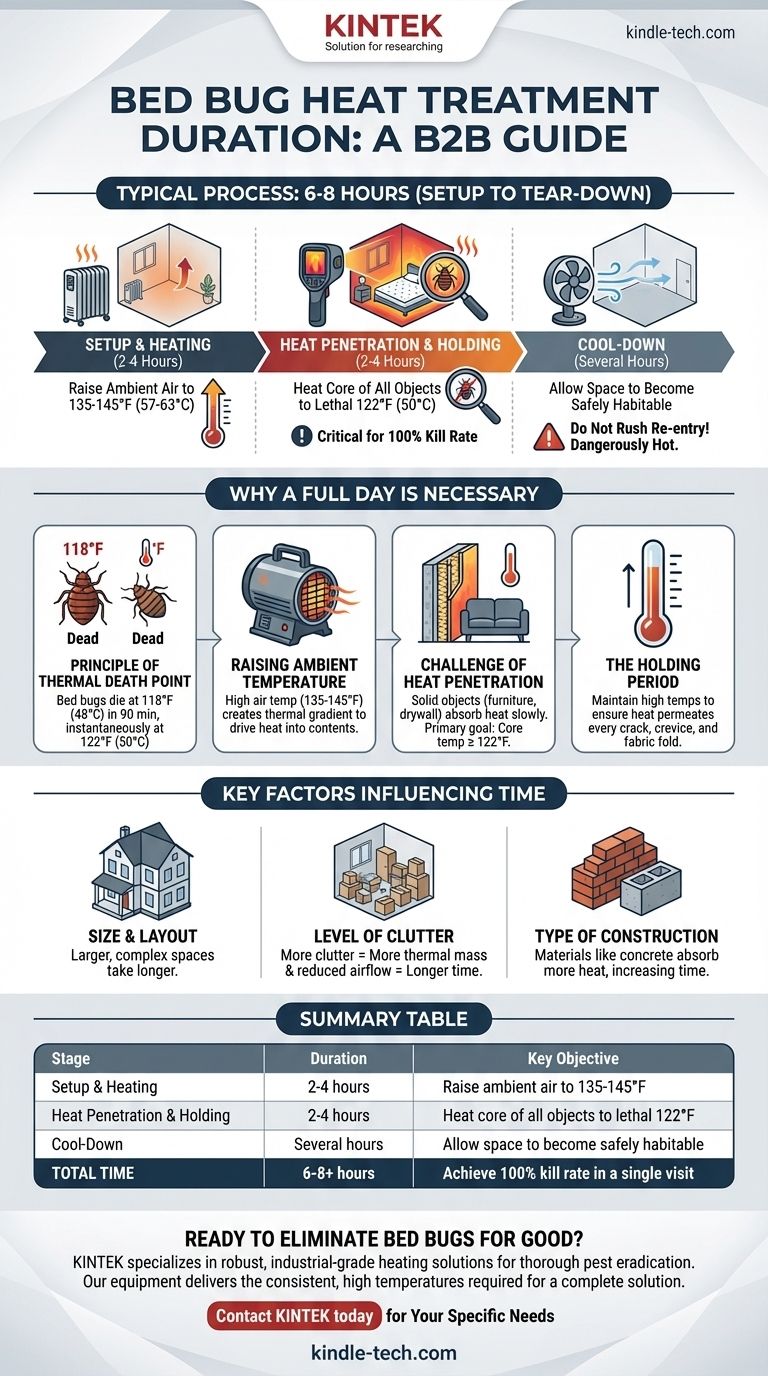

For a typical bed bug heat treatment, the entire process usually takes between six and eight hours to complete from setup to tear-down. While the insects themselves die relatively quickly at lethal temperatures, the majority of this time is spent ensuring that heat fully penetrates every object and hiding spot in the treatment area.

The critical factor isn't how long it takes to kill a bed bug in open air, but how long it takes to heat the core of the most insulated object in a room—like a mattress or sofa—to the lethal temperature and hold it there.

Why a Full Day is Necessary

A professional heat treatment is a methodical process. The time required is dictated by the laws of thermodynamics and the goal of achieving a 100% kill rate, leaving no cold spots where pests could survive.

The Principle of Thermal Death Point

The foundation of the treatment is simple science. Bed bugs and their eggs die when exposed to specific temperatures for a certain duration.

According to research, bed bugs and their eggs die in 90 minutes at 118°F (48°C). At 122°F (50°C), they die almost instantaneously.

Raising the Ambient Temperature

To achieve this, professionals use powerful, specialized heaters to raise the ambient air temperature in the room to between 135°F (57.2°C) and 145°F (62.7°C).

This much higher air temperature creates a significant thermal gradient, which is necessary to drive heat into all the contents of the room effectively.

The Challenge of Heat Penetration

This is the most time-consuming phase of the treatment. Air heats up quickly, but solid objects like furniture, books, and drywall absorb heat very slowly.

The primary goal is to ensure the core temperature of every item and structural void reaches the lethal target of at least 122°F. Technicians use thermal sensors and infrared thermometers to monitor the hardest-to-heat locations, often called cold spots.

The Holding Period

Once the coldest spot in the treatment area reaches the target temperature, a "holding period" begins. The high temperatures are maintained for a sustained period to guarantee that heat has permeated every last crack, crevice, and fabric fold, ensuring a complete kill.

Key Factors That Influence Treatment Time

While 6-8 hours is a reliable average, several variables can extend or shorten the process.

Size and Layout of the Space

A larger home with multiple rooms and complex layouts will naturally take longer to heat than a single, small room or studio apartment.

Level of Clutter

This is one of the most significant factors. A cluttered room contains more "thermal mass"—objects that must be heated through. This dramatically increases the time required for full heat penetration and reduces airflow, creating more potential cold spots.

Type of Construction

The building materials themselves play a role. For instance, concrete floors and plaster walls absorb a tremendous amount of heat and can increase the time needed to reach the target temperature compared to a standard wood-frame and drywall structure.

The Non-Negotiable Part of the Process: The Cool-Down

The treatment doesn't end the moment the heaters are turned off. A critical, and often overlooked, part of the timeline is allowing the space to cool down.

Why You Can't Rush Re-entry

The treated area will be dangerously hot for several hours after the equipment is removed. Attempting to re-enter too soon is unsafe.

This cool-down period must be factored into your plans, as it adds several hours to the total time before the space is habitable again.

Making the Right Choice for Your Goal

When planning for a heat treatment, it's best to set aside a full day. Understanding the variables helps you prepare for the most effective outcome.

- If your primary focus is a small, lightly furnished area: You can likely expect the process to be on the shorter end of the 6-hour estimate.

- If your primary focus is a larger, multi-room, or cluttered home: You should plan for a full 8-hour day, and potentially longer, to ensure a thorough result.

- Regardless of your situation: Always account for a multi-hour cool-down period before you can safely return to the treated space.

Ultimately, understanding the complete timeline ensures you are prepared for a process designed to solve the problem comprehensively in a single visit.

Summary Table:

| Stage | Duration | Key Objective |

|---|---|---|

| Setup & Heating | 2-4 hours | Raise ambient air to 135-145°F (57-63°C) |

| Heat Penetration & Holding | 2-4 hours | Heat core of all objects to lethal 122°F (50°C) |

| Cool-Down | Several hours | Allow space to become safely habitable |

| Total Time | 6-8+ hours | Achieve 100% kill rate in a single visit |

Ready to eliminate bed bugs for good?

A successful heat treatment requires precise temperature control and reliable equipment to ensure every hiding spot reaches the lethal threshold. KINTEK specializes in the robust, industrial-grade heating solutions needed for thorough pest eradication.

Our equipment delivers the consistent, high temperatures required to penetrate deep into furniture and structures, guaranteeing a complete solution. Let us provide you with the right tools for a 100% effective treatment.

Contact KINTEK today to discuss your specific needs and ensure your next heat treatment is a total success.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What precautions should be observed during heat treatment? Essential Safety Protocols for Your Lab

- Why is a thin film circuit important? Achieve Unmatched Precision for High-Frequency Electronics

- What are the advantages of pyrolysis over incineration? Achieve Cleaner Waste Transformation with Resource Recovery

- What is the difference between balanced and unbalanced magnetron? Choose the Right Tool for Your Thin-Film Process

- What is diffusion in sintering? Unlocking the Atomic Mechanism for Stronger Materials

- Why is continuous stirring equipment utilized during the drying impregnation stage? Ensure Catalyst Activity & Stability

- What is the difference between AC and DC sputtering? Choose the Right Method for Your Material

- What is the manufacturing process of sintering? A Guide to Solid-State Powder Bonding