The force a hydraulic press can produce varies dramatically, ranging from a few thousand pounds for a small workshop press to many millions of pounds for massive industrial machines. For example, a common 20 kg (44 lb) benchtop press might have a recommended working force of 9,500 kg (about 21,000 pounds) and a maximum structural limit of 15,200 kg (over 33,000 pounds). The force is not a single number but a function of the machine's design and operating pressure.

A hydraulic press does not have one fixed force output. Its capability is defined by its tonnage rating, which is determined by the hydraulic pressure it can generate and the size of its piston. This can range from under 10 tons for benchtop models to over 50,000 tons for industrial forging presses.

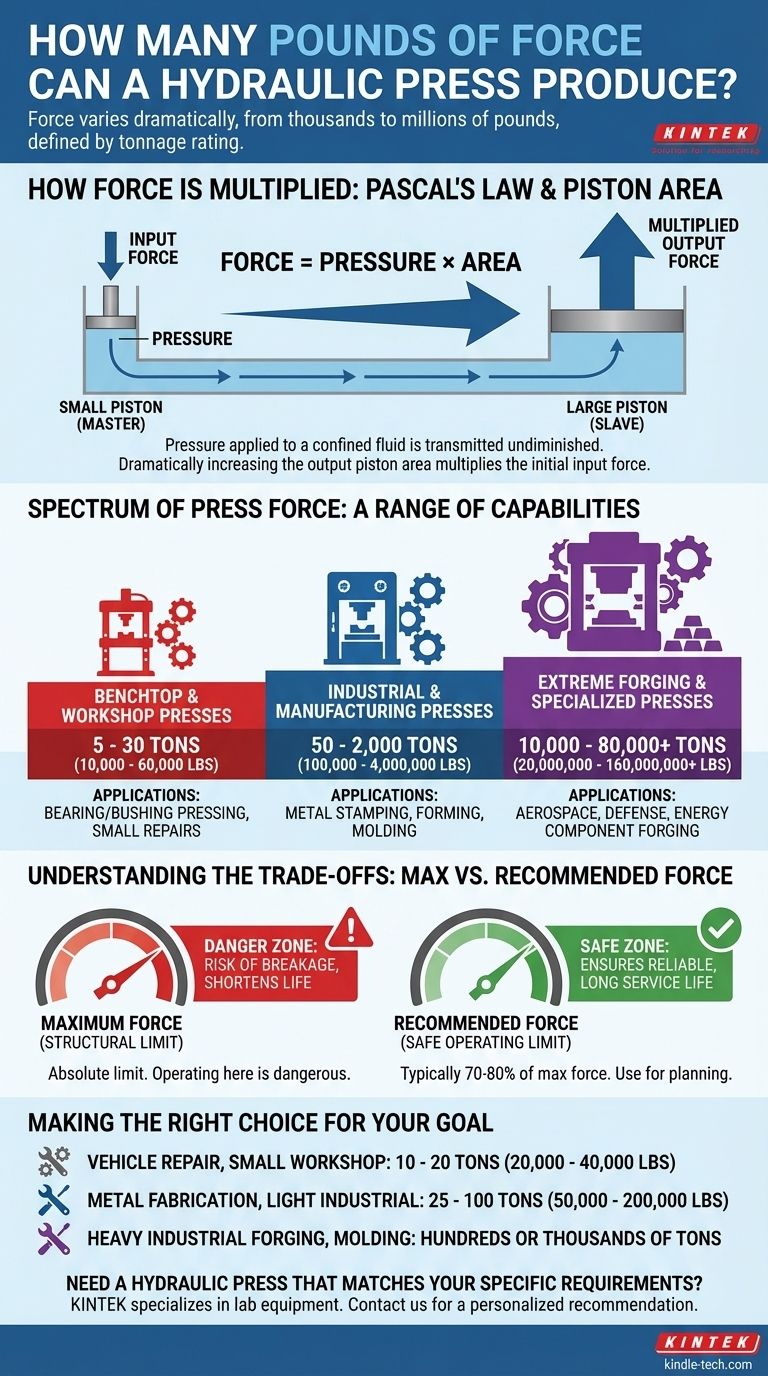

How a Hydraulic Press Multiplies Force

To understand the capability of any press, you must first grasp the principle that makes it work. The immense force is not created from nothing; it is multiplied.

The Core Principle: Pascal's Law

A hydraulic press operates on Pascal's Law, which states that pressure applied to a confined fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

Imagine applying a small amount of force to a small piston (the master cylinder). This creates pressure in the hydraulic fluid.

The Force Multiplier: Piston Area

This pressure travels through the fluid to a much larger piston (the slave cylinder). Because the surface area of this second piston is much larger, the same pressure exerts a proportionally larger total force.

The formula is simple: Force = Pressure × Area. By dramatically increasing the area of the output piston, the system multiplies the initial input force many times over.

Why Force is Measured in Tonnage

In industry, the force of a hydraulic press is almost always rated in tons. This provides a standardized way to compare the maximum force a press can exert. A 20-ton press can exert 40,000 pounds of force, while a 1,000-ton press can exert 2,000,000 pounds.

The Spectrum of Press Force

The tonnage of a press is directly related to its intended application, leading to a vast range of sizes and capabilities.

Benchtop and Workshop Presses

These are the most common types found in repair shops and small fabrication facilities. They are typically used for tasks like pressing bearings, bushings, or straightening small parts.

Their force ratings usually fall between 5 and 30 tons (10,000 to 60,000 pounds). The press described in the technical specifications, with its 9.5-ton recommended force, is a classic example of this category.

Industrial and Manufacturing Presses

These are much larger machines used for processes like metal forming, stamping, molding, and forging. Their capabilities are scaled to the demands of production.

These presses can range from 50 tons to over 2,000 tons (100,000 to over 4,000,000 pounds). They are the workhorses of heavy manufacturing.

Extreme Forging and Specialized Presses

At the highest end are the machines used for forging massive components for the aerospace, defense, and energy sectors.

These colossal presses can achieve forces of 10,000 to 80,000 tons or more, which translates to tens or even hundreds of millions of pounds of force, capable of shaping huge ingots of steel or titanium.

Understanding the Trade-offs: Maximum vs. Recommended Force

When evaluating a press, you will often see two different force ratings. Understanding the distinction is critical for safety and machine longevity.

What 'Maximum Force' Really Means

The maximum force (or "maximum power allowed") is the absolute structural and hydraulic limit of the machine. It is the point beyond which something is likely to break—be it the frame, the seals, or the cylinder itself.

Operating at or near this limit is dangerous and will drastically shorten the life of the press. It is a specification of capacity, not a target for regular operation.

The Importance of 'Recommended Force'

The recommended force (or "working force") is the safe, continuous operating limit specified by the manufacturer. This value is typically 70-80% of the absolute maximum force.

Working within this recommended range ensures the machine operates without undue stress on its components, leading to a long and reliable service life. For any practical purpose, this is the number you should use for planning your work.

Making the Right Choice for Your Goal

Selecting a press requires matching its force capability to your specific task. Using a press with insufficient tonnage will fail to do the job, while using one with excessive force can be inefficient and create a higher risk of damaging the part or operator.

- If your primary focus is vehicle repair or small workshop tasks: A press rated for 10 to 20 tons (20,000 to 40,000 lbs) provides ample force for jobs like pressing bearings, U-joints, and bushings.

- If your primary focus is metal fabrication or light industrial work: Look for presses in the 25 to 100-ton range (50,000 to 200,000 lbs) for stamping, forming, and assembly operations.

- If your primary focus is heavy industrial forging or molding: You require a specialized press where the force, measured in hundreds or thousands of tons, is engineered specifically for the application.

Ultimately, understanding the relationship between pressure, area, and tonnage empowers you to select the right tool and use it safely and effectively.

Summary Table:

| Press Type | Typical Tonnage Range | Approximate Pound Force Range | Common Applications |

|---|---|---|---|

| Benchtop/Workshop | 5 - 30 tons | 10,000 - 60,000 lbs | Bearing/bushing pressing, small repairs |

| Industrial/Manufacturing | 50 - 2,000 tons | 100,000 - 4,000,000 lbs | Metal stamping, forming, molding |

| Extreme Forging/Specialized | 10,000 - 80,000+ tons | 20,000,000 - 160,000,000+ lbs | Aerospace, defense, energy component forging |

Need a hydraulic press that matches your specific force requirements? KINTEK specializes in lab equipment and consumables, offering a range of hydraulic presses tailored to your laboratory's needs. Our experts can help you select the perfect press with the right tonnage for your applications, ensuring safety, efficiency, and longevity. Contact us today to discuss your project and get a personalized recommendation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Lab Heat Press

People Also Ask

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability