There is no fixed number of times you can use a crucible. Its lifespan is not measured in a set number of uses but by its condition, which is determined by material, temperature, contents, and handling. A well-maintained silicon carbide crucible used under ideal conditions might last for dozens of melts, while a clay-graphite crucible subjected to thermal shock and aggressive flux could fail on its second use.

The central takeaway is to shift your mindset: a crucible's lifespan isn't a number you count up to, but a condition you must constantly evaluate. Your primary job is not to maximize uses, but to identify the signs of failure before it happens.

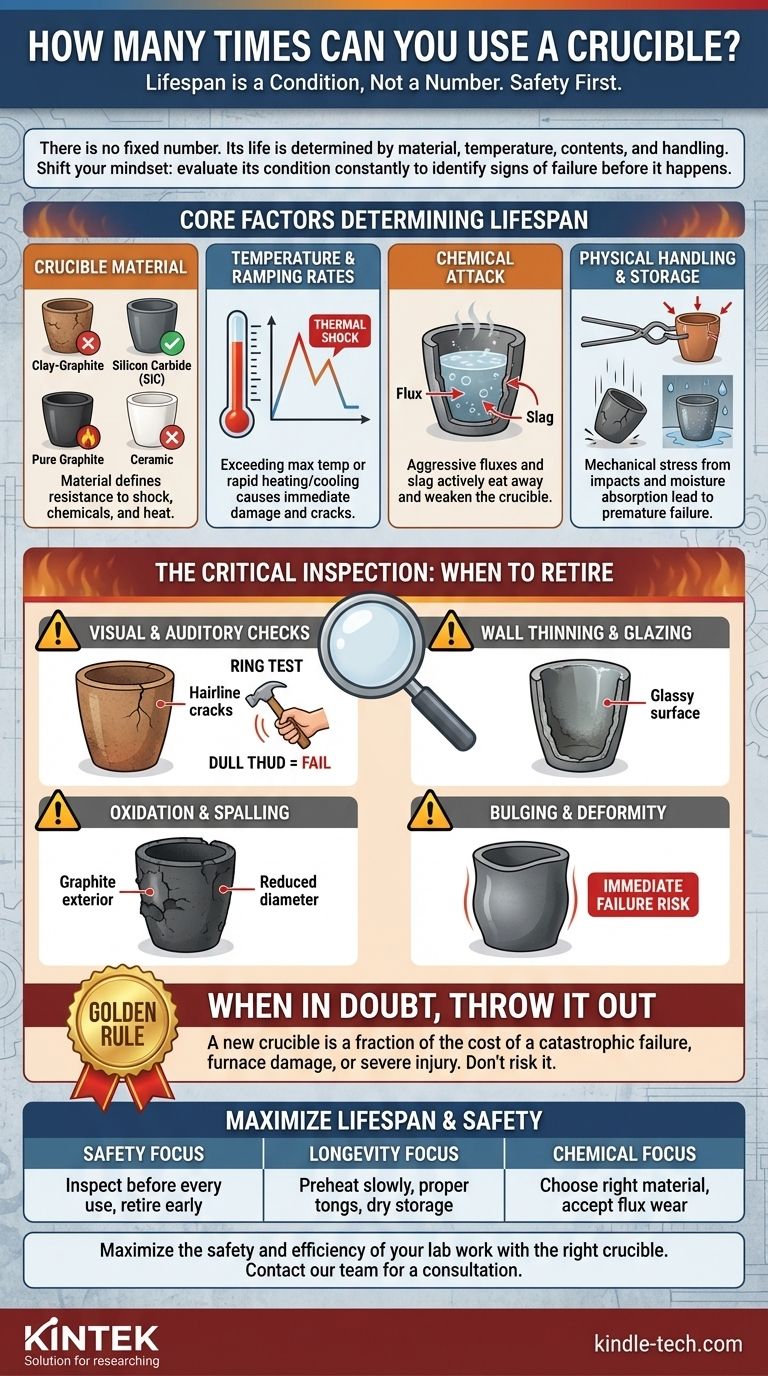

The Core Factors That Determine Crucible Lifespan

A crucible is a consumable tool, but several key factors directly influence how long it will remain safely in service. Understanding them is critical to both safety and efficiency.

Crucible Material

The material is the most significant factor. Each type has distinct properties.

- Clay-Graphite: A common and affordable choice, but it is more susceptible to thermal shock and physical damage.

- Silicon Carbide (SiC): More expensive but offers superior strength and excellent resistance to thermal shock. They generally offer a much longer service life.

- Pure Graphite: Excellent for high temperatures but oxidizes (burns away) in the presence of oxygen, especially at the rim. Its lifespan is often measured in how quickly it degrades.

- Ceramic (e.g., Alumina, Zirconia): Used for specialty applications. They have very high temperature resistance but are often brittle and can crack easily from thermal shock or physical impact.

Operating Temperature and Ramping Rates

Extreme heat is the primary stressor.

- Exceeding Maximum Temperature: Pushing a crucible beyond its rated temperature, even briefly, can cause immediate and irreversible structural damage.

- Thermal Shock: The most common killer of crucibles is rapid heating or cooling. This creates internal stress that leads to cracks. Proper pre-heating and controlled cooling are non-negotiable for extending crucible life.

Chemical Attack from Contents

What you melt inside the crucible actively works to destroy it.

- Flux: Many fluxes, especially those containing borax or soda ash, are designed to be chemically aggressive. They will actively eat away at the crucible wall, particularly those containing silica.

- Slag: The impurities that float to the top of a melt can be highly corrosive and can etch or "glaze" the interior, weakening the structure over time.

Physical Handling and Storage

Mechanical stress is an easily avoidable cause of premature failure.

- Improper Tongs: Using tongs that don't fit correctly can create pressure points, leading to cracks. Steel tools scraping the inside or outside will also cause damage.

- Impact: Dropping a crucible, even from a small height, can create micro-fractures that are not immediately visible but will fail catastrophically under heat.

- Storage: Storing a crucible in a damp or humid environment allows it to absorb moisture. When heated, this moisture turns to steam and can crack the crucible from the inside out. Always store them in a warm, dry place.

The Critical Inspection: When to Retire a Crucible

You must inspect your crucible before every single use. This is your most important safety check. Look for these undeniable signs of impending failure.

Visual and Auditory Checks for Cracks

A crack of any size is a death sentence for a crucible.

- Hairline Fissures: Carefully examine the entire surface, especially around the rim, base, and pouring spout. A small crack will quickly become a large one at temperature.

- The "Ring Test": Gently tap the side of a cool, empty crucible with a piece of wood or your knuckle. A healthy crucible will produce a clear, high-pitched ringing sound. A damaged one will sound like a dull thud, indicating a hidden crack.

Wall Thinning and Glazing

The interior surface tells a story of chemical wear.

- Erosion: Feel the walls for any thin spots or noticeable degradation, especially just below the typical fill line.

- Glazing: A shiny, glassy interior surface indicates that flux has deeply penetrated and reacted with the crucible material, making it brittle.

Oxidation and Spalling

This is especially relevant for graphite-based crucibles.

- Spalling: Look for any flaking or peeling on the exterior surface. This shows the graphite is oxidizing and losing structural mass.

- Reduced Diameter: If the crucible's outer walls look "eaten away" or noticeably thinner than when new, its structural integrity is compromised.

Bulging or Deformity

Any change in shape is a major red flag. If the crucible is bulging or warped, it has lost its structural rigidity and is at extreme risk of failure. Retire it immediately.

Understanding the Trade-offs: Pushing Limits vs. Ensuring Safety

It can be tempting to try and get "one more use" out of a worn crucible to save money. This is a dangerous and costly calculation.

The Cost of a Failure

A crucible failure during a melt is a catastrophic event. It results in the loss of your molten material, potential damage or destruction of your furnace, and most importantly, an extremely dangerous risk of fire and severe burns.

The Myth of "Just One More"

If you are questioning whether a crucible is safe to use, it isn't. The very presence of a visible crack, a dull ring, or significant wall thinning means the crucible has already failed its inspection.

The Golden Rule: When in Doubt, Throw It Out

A new crucible costs a fraction of a new furnace, a trip to the emergency room, or rebuilding your workshop. There is no economic or practical justification for taking the risk.

How to Maximize Your Crucible's Lifespan

Follow these principles to get the most safe and effective service from your equipment.

- If your primary focus is safety (as it should be): Inspect the crucible before every use and retire it at the first sign of a crack, bulge, or significant wear.

- If your primary focus is extending longevity: Always preheat your crucible slowly, avoid rapid cooling, use properly fitting tongs, and store it in a warm, dry location.

- If your primary focus is managing chemical attack: Choose a crucible material rated for your specific application and accept that aggressive fluxes will inevitably shorten its life.

Ultimately, treating your crucible as a critical piece of safety equipment, not just a consumable pot, is the key to safe and successful work.

Summary Table:

| Factor | Impact on Lifespan | Key Consideration |

|---|---|---|

| Material | Most significant | Silicon carbide lasts longer; clay-graphite is more susceptible to shock. |

| Temperature & Ramping | High stressor | Avoid exceeding max temperature and thermal shock with controlled heating/cooling. |

| Chemical Attack | Actively degrades | Fluxes and slag can corrode walls; choose material rated for your application. |

| Handling & Storage | Avoidable damage | Use proper tongs, avoid impact, and store in a warm, dry place to prevent moisture absorption. |

Maximize the safety and efficiency of your lab work with the right crucible for your application.

At KINTEK, we specialize in providing high-quality laboratory equipment and consumables, including a wide range of crucibles designed for durability and performance. Whether you're working with high temperatures, aggressive fluxes, or need superior thermal shock resistance, our experts can help you select the perfect crucible to extend its lifespan and protect your lab.

Don't compromise on safety—contact our team today for a personalized consultation and ensure your next melt is both successful and secure.

Visual Guide

Related Products

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

People Also Ask

- What is a crucible material for a furnace? A Guide to Choosing the Right High-Temperature Container

- What are the safety precautions of a crucible? Protect Your Lab from Thermal Shock and Hazards

- What is the temperature range of alumina crucibles? Key Factors for Safe High-Temp Use

- How much heat can a ceramic crucible withstand? A Guide to Material-Specific Temperature Limits

- What is a crucible porcelain? Choosing the Right High-Temperature Lab Vessel