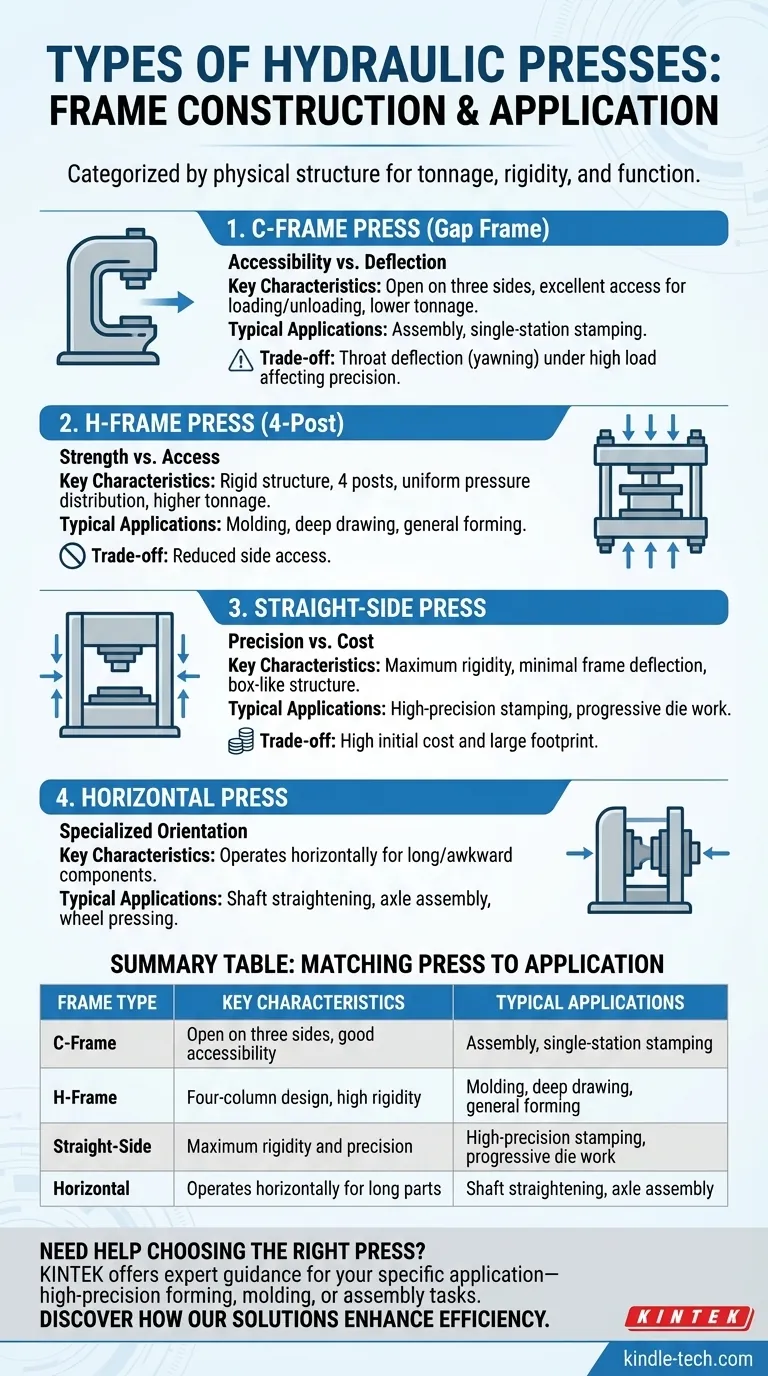

While there is no single definitive number, hydraulic presses are most commonly categorized by their physical frame structure. The main types are the C-frame (or gap frame), the H-frame (or 4-post), the straight-side press, and the less common horizontal press. These designs are then further specialized based on their intended function, such as forging, stamping, or forming.

The "type" of a hydraulic press is fundamentally defined by its frame. This physical structure is the most important factor as it dictates the machine's tonnage capacity, rigidity, and overall suitability for specific manufacturing operations.

The Primary Classification: Frame Construction

The frame is the backbone of the press. Its design determines how it handles the immense forces generated during an operation and dictates the kind of work it can perform effectively.

The C-Frame Press (Gap Frame)

The C-frame press has a distinctive shape like the letter "C." The work area is open on three sides, offering excellent access for loading, unloading, and integrating automation.

These presses are typically used for applications requiring lower tonnage. Their open design makes them ideal for assembly, single-station stamping, and jobs where operators need easy access to the die area.

The H-Frame Press (4-Post)

An H-frame press, also known as a 4-column or 4-post press, provides a much more rigid and evenly supported structure. The ram and bolster are supported by four posts, which ensures the force is distributed evenly across the workpiece.

This design is the standard for higher-tonnage applications. H-frames are commonly used for molding, deep drawing, and other forming jobs that demand significant force and stability over a large surface area.

The Straight-Side Press

Straight-side presses are an evolution of the H-frame, built for maximum rigidity and precision. They use solid steel frames or pre-stressed tie rods to create an extremely robust, box-like structure.

These machines are engineered to minimize any frame deflection under load, making them essential for high-precision stamping, progressive die operations, and deep drawing where consistent accuracy is critical. They represent the high-end of performance and rigidity.

The Horizontal Press

As the name implies, these presses operate horizontally rather than vertically. This orientation is specialized for specific tasks that are impractical on a vertical press.

Common applications include straightening long shafts or plates, pressing wheels or bearings onto axles, and other assembly operations on elongated parts.

Understanding the Trade-offs

Choosing a press type involves balancing performance, accessibility, and cost. Each design has inherent strengths and weaknesses.

C-Frame: Accessibility vs. Deflection

The greatest strength of the C-frame is its accessibility. However, its open front design can lead to "throat deflection" or "yawning" under very high tonnage, where the C-shape slightly opens. This can compromise the parallelism of the die and affect part accuracy.

H-Frame: Strength vs. Access

The H-frame provides excellent strength and uniform pressure distribution, making it a reliable workhorse. The trade-off is reduced access to the work area from the sides, which can be a limitation for certain part handling or automation setups.

Straight-Side: Precision vs. Cost

Straight-side presses offer the highest level of precision and rigidity available, virtually eliminating frame deflection. This performance comes at a significantly higher initial cost and a larger machine footprint compared to other types of similar tonnage.

Matching the Press to the Application

To select the correct machine, you must align the press's fundamental design with your primary operational goal. The applications you mentioned—forging, punching, deep drawing, and forming—each place different demands on a press.

- If your primary focus is assembly or smaller-part stamping: A C-frame press is your most practical choice due to its excellent access and lower cost.

- If your primary focus is general-purpose molding or forming at high tonnage: An H-frame press offers the best balance of power, stability, and value.

- If your primary focus is high-volume, high-precision deep drawing or progressive stamping: A straight-side press is necessary to ensure the required accuracy and tool life.

- If your primary focus is working on long or awkwardly shaped components: A horizontal press may be the only effective solution for your specific application.

Understanding the core differences in frame construction empowers you to look beyond simple specifications and choose the right tool for the job.

Summary Table:

| Frame Type | Key Characteristics | Typical Applications |

|---|---|---|

| C-Frame | Open on three sides, good accessibility | Assembly, single-station stamping |

| H-Frame | Four-column design, high rigidity | Molding, deep drawing, general forming |

| Straight-Side | Maximum rigidity and precision | High-precision stamping, progressive die work |

| Horizontal | Operates horizontally for long parts | Shaft straightening, axle assembly |

Still unsure which hydraulic press is right for your lab or production line? KINTEK specializes in lab equipment and consumables, offering expert guidance to help you select the perfect hydraulic press for your specific application—whether it's for high-precision forming, molding, or assembly tasks. Contact our team today to discuss your requirements and discover how our solutions can enhance your operational efficiency and accuracy!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability