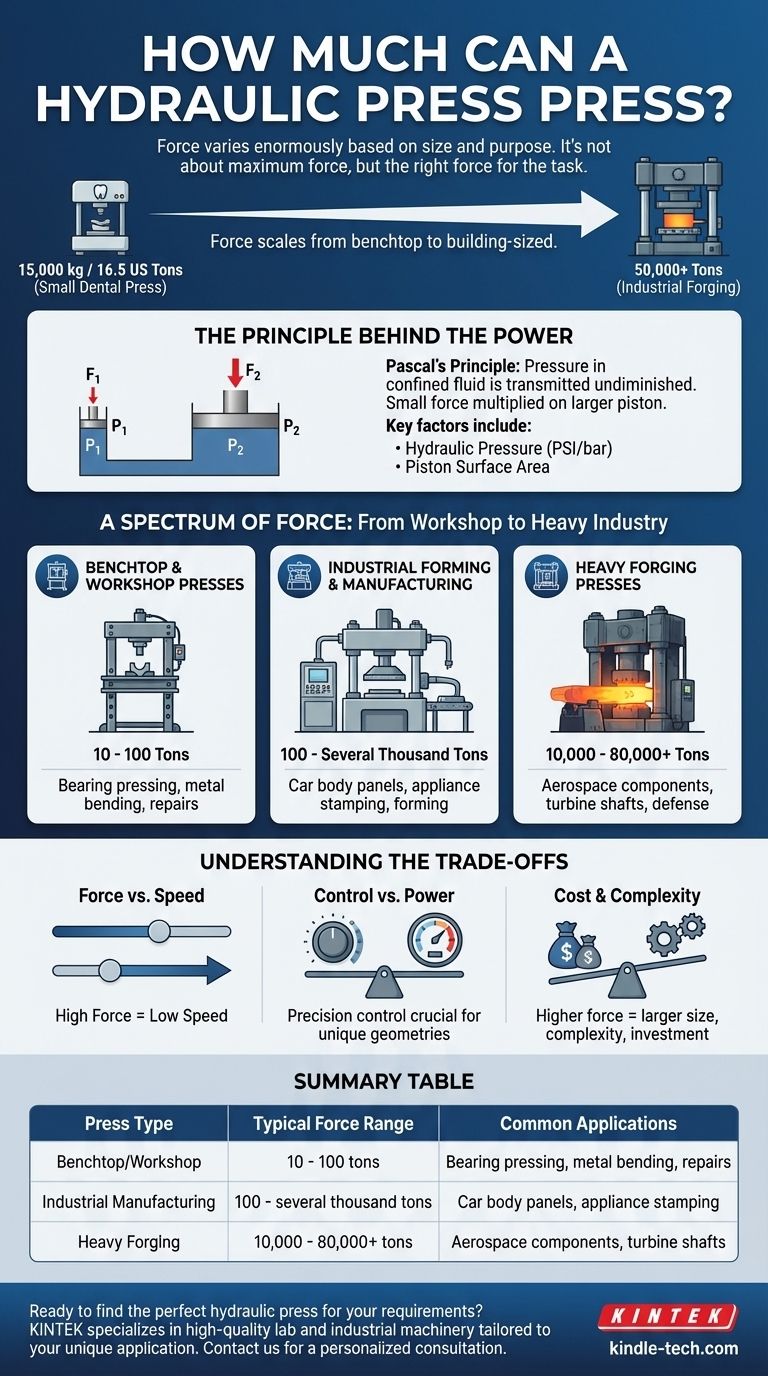

To be direct, the pressing force of a hydraulic press varies enormously based on its size and purpose. A small dental press can exert a force of 15,000 kilograms (about 16.5 US tons), while massive industrial forging presses can generate forces exceeding 50,000 tons. The answer depends entirely on the specific application the press was designed for.

The question is not "how much can a press press," but rather "what force is required for a specific task?" The power of a hydraulic press is a direct function of its design, scaling from small benchtop units to building-sized industrial machines.

The Principle Behind the Power

To understand the vast range of forces, you first need to understand the simple principle that makes it all possible.

The Power of Force Multiplication

A hydraulic press operates on Pascal's Principle. This law of physics states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid.

In a press, a small force is applied to a small piston, which creates pressure in the hydraulic fluid. This pressure then acts on a much larger piston, multiplying the initial force exponentially.

This is how a relatively light machine, like a 20 kg dental press, can generate a crushing force of 15,000 kg. It's a masterful application of mechanical advantage.

Key Factors Determining Force

The final output force of a hydraulic press is determined by two primary factors:

- Hydraulic Pressure: The pressure generated by the pump, measured in pounds per square inch (PSI) or bar.

- Piston Surface Area: The size of the piston face that the pressurized fluid pushes against.

A larger piston area or higher system pressure will result in a greater output force.

A Spectrum of Force: From Workshop to Heavy Industry

The application dictates the required force, leading to a massive spectrum of press sizes and capabilities.

Benchtop and Workshop Presses

These are the most common types of presses, found in machine shops, garages, and small-scale manufacturing.

Their force typically ranges from 10 to 100 tons. They are used for tasks like pressing bearings, bending metal, and general assembly or repair work. The dental press mentioned in the reference, with its 16.5-ton capacity, fits into the lower end of this category.

Industrial Forming and Manufacturing Presses

These are significantly larger machines used in factory production lines for shaping and forming metal parts.

These presses can range from 100 to several thousand tons. They are essential for manufacturing car body panels, appliance housings, and other large-scale stamped components.

Heavy Forging Presses

At the absolute peak of the scale are the heavy forging presses used to shape massive pieces of metal, called ingots or billets.

These colossal machines can exert forces from 10,000 to over 80,000 tons. They forge critical components for the aerospace, defense, and power generation industries, such as aircraft landing gear or turbine shafts.

Understanding the Trade-offs

Choosing or designing a hydraulic press involves balancing competing factors. It's never just about achieving the maximum possible force.

Force vs. Speed

There is often an inverse relationship between force and speed. Presses designed for extremely high tonnage typically move very slowly to allow the immense pressure to build and act on the workpiece.

Control vs. Power

As the reference material notes, a key advantage of hydraulic systems is control over speed and pressure. For delicate or complex operations, this precision can be more important than raw force. Forging unique geometries requires careful modulation, not just maximum crushing power.

Cost and Complexity

Unsurprisingly, as the force capacity increases, so do the size, complexity, and cost of the machine. A 50,000-ton press is a monumental piece of engineering requiring a massive foundation and infrastructure, representing a significant capital investment.

Matching the Press to the Purpose

The right amount of force is the amount needed for your specific goal.

- If your primary focus is workshop repair or small fabrication: A press in the 10-50 ton range is typically the most versatile and cost-effective choice.

- If your primary focus is specialized manufacturing: The force requirement is dictated entirely by the material and process, where precision control may be as crucial as tonnage.

- If your primary focus is heavy industrial forging: You are in the realm of custom-engineered machines where force is measured in the tens of thousands of tons.

Ultimately, the capability of a hydraulic press is defined by its intended task, not by an arbitrary limit.

Summary Table:

| Press Type | Typical Force Range | Common Applications |

|---|---|---|

| Benchtop/Workshop | 10 - 100 tons | Bearing pressing, metal bending, repairs |

| Industrial Manufacturing | 100 - several thousand tons | Car body panels, appliance stamping |

| Heavy Forging | 10,000 - 80,000+ tons | Aerospace components, turbine shafts |

Ready to find the perfect hydraulic press for your specific force and control requirements?

KINTEK specializes in providing high-quality lab equipment and industrial machinery, including hydraulic presses tailored to your unique application—whether for a research laboratory, a workshop, or a large-scale manufacturing line. Our experts can help you select a press that delivers the precise force, speed, and control you need.

Contact us today for a personalized consultation and discover how the right press can enhance your efficiency and results.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System