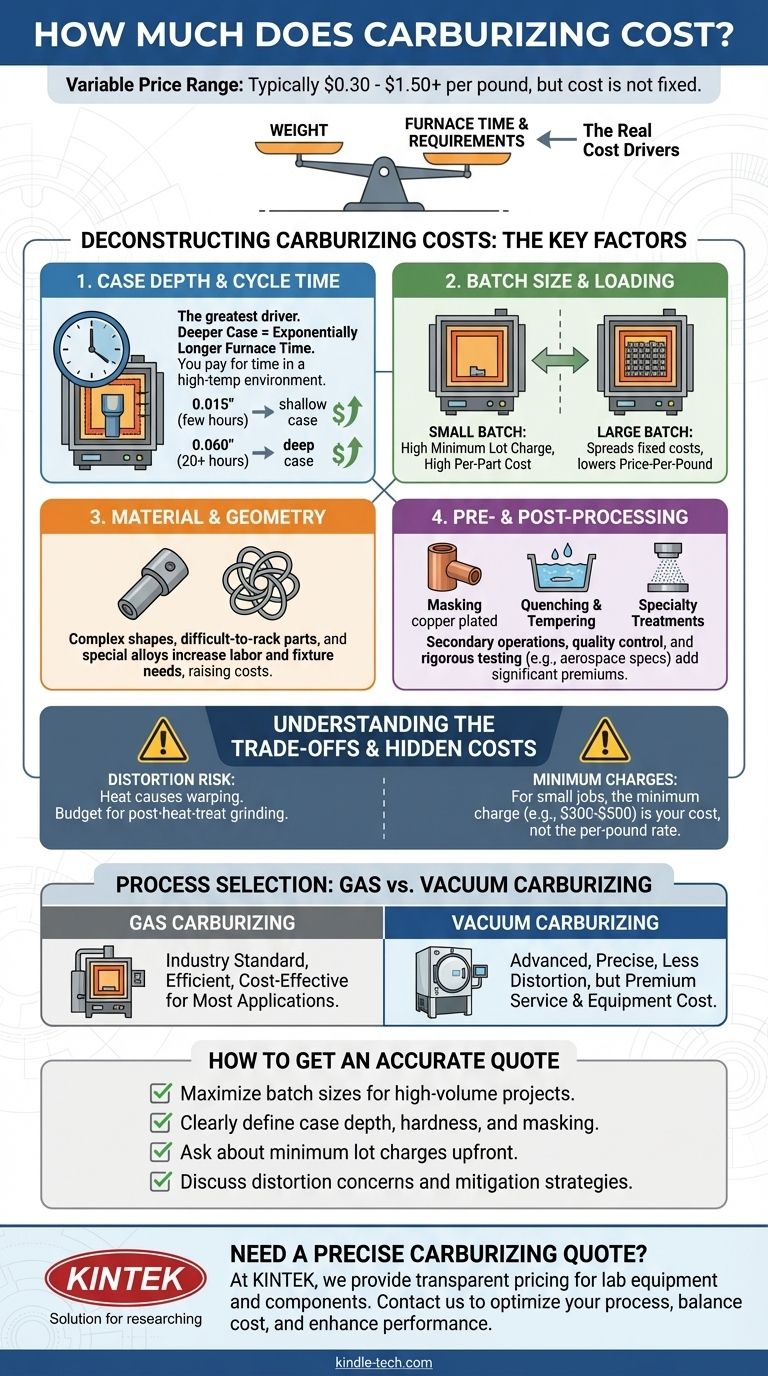

In reality, there is no single, fixed price for carburizing. The cost is highly variable, typically ranging from $0.30 to over $1.50 per pound, but this figure is heavily influenced by specific technical requirements, part geometry, and order volume. The final price is less about the weight and more about the furnace time and specialized handling your project demands.

The total cost of carburizing is not a simple commodity price but a calculation based on furnace cycle time, batch size, material composition, and any required secondary operations. Understanding these cost drivers is the key to accurately budgeting for the process and securing a fair price.

Deconstructing Carburizing Costs: The Key Factors

To understand a quote from a heat treater, you must first understand what you are paying for. The cost is an aggregate of several critical process variables.

The Dominant Factor: Case Depth and Cycle Time

The single greatest driver of carburizing cost is the required case depth. Achieving a deeper hardened case requires exponentially longer furnace times.

Furnace time is the most valuable and expensive resource in a heat treatment facility. A shallow case depth of 0.015" might take a few hours, while a deep case of 0.060" could require the furnace to run for 20 hours or more. You are essentially paying rent for time in a highly specialized, high-temperature environment.

Economies of Scale: Batch Size and Furnace Loading

A heat treater's goal is to run a full furnace whenever possible. The cost to run a furnace cycle is relatively fixed, whether it contains 100 pounds or 2,000 pounds of parts.

This is why batch size is so critical. A large, heavy batch allows the fixed operational cost to be spread across more parts, dramatically lowering the price-per-pound. Conversely, a very small batch will likely incur a minimum lot charge that can make the per-part cost seem exceptionally high.

Material and Part Geometry

The part itself influences the cost. Certain low-alloy steels like 8620, 4320, and 9310 are standard for carburizing and require no special considerations.

However, complex part geometries can increase costs. Parts that are difficult to rack, prone to tangling, or require special fixtures demand more labor for loading and unloading. Extremely large or heavy parts may require specialized equipment that not all facilities possess.

Pre- and Post-Processing Requirements

Carburizing is rarely a standalone process. The cost of these necessary secondary operations must be factored into the total price.

- Masking: If certain surfaces must remain soft, they are often protected with copper plating or specialized stop-off paints. This is a labor-intensive step that adds significant cost.

- Quenching & Tempering: All carburized parts must be quenched and then tempered to achieve the final desired properties. This is usually included in the base carburizing price.

- Specialty Treatments: Additional processes like cryogenic treatment (for converting retained austenite) or shot peening (for improved fatigue life) are separate services with their own costs.

Quality Control and Certification

The level of documentation and testing required directly impacts the price. A general industrial part may only need a hardness test and a basic certification.

In contrast, aerospace or medical components demand extensive metallurgical testing, microstructural analysis, detailed reports, and lot traceability. This rigorous quality assurance adds a significant premium to the service.

Understanding the Trade-offs and Hidden Costs

Focusing solely on the price-per-pound can lead to unexpected expenses and production issues down the line.

The Inevitable Risk of Distortion

Carburizing involves heating parts to over 1700°F (925°C) and then rapidly cooling (quenching) them. This thermal shock inherently introduces stress and can cause parts to warp, shrink, or grow.

While skilled heat treaters work to minimize distortion, it can never be eliminated entirely. You must budget for the possibility of needing post-heat-treat grinding or machining to bring critical dimensions back into tolerance. This can be a major hidden cost.

The Trap of "Minimum Lot Charges"

For prototypes or small repair jobs, the minimum lot charge is often the entire cost. A heat treater may have a minimum charge of $300-$500 or more to cover the cost of running a furnace cycle. If you are only carburizing 10 pounds of parts, your effective price is $30-$50 per pound, not the "standard" rate.

Process Selection: Gas vs. Vacuum Carburizing

Gas carburizing is the industry standard—it is efficient, reliable, and cost-effective for most applications.

Vacuum carburizing (or low-pressure carburizing) is a more advanced, precise process that offers better uniformity and can reduce distortion. However, the equipment is far more expensive to own and operate, making it a premium service reserved for the most demanding applications. Expect to pay a significant surcharge for vacuum carburizing.

How to Get an Accurate Quote

To get a reliable and competitive price for your project, you must provide your heat treater with a complete and accurate set of specifications.

- If your primary focus is minimizing cost on a high-volume project: Maximize your batch sizes and provide your heat treater with drawings well in advance to discuss opportunities for simplifying part handling.

- If your primary focus is achieving precise technical specifications: Clearly define the required effective case depth, surface hardness, core hardness, and any areas that require masking.

- If you are working with a small batch or prototype: Ask about minimum lot charges upfront and inquire if your job can be scheduled alongside other parts with similar requirements to reduce costs.

- If your part is prone to distortion: Discuss this concern with your heat treater, as they may suggest press quenching, fixture quenching, or adjusted process parameters to mitigate the risk.

Providing clear and detailed information is the most effective way to ensure you receive an accurate quote that aligns with your project's technical and financial goals.

Summary Table:

| Cost Factor | Impact on Price | Key Consideration |

|---|---|---|

| Case Depth | High | Deeper case = exponentially longer furnace time. |

| Batch Size | High | Larger batches lower the cost-per-pound significantly. |

| Part Geometry | Medium | Complex parts may require special fixtures or handling. |

| Material Type | Low | Standard alloys (e.g., 8620) are most cost-effective. |

| Quality Control | Variable | Aerospace/medical certifications add a premium. |

| Secondary Operations | Variable | Masking, grinding, or special treatments increase cost. |

Need a precise carburizing quote for your lab equipment or components?

At KINTEK, we specialize in providing transparent, detailed pricing for heat treatment services tailored to the unique needs of laboratories and research facilities. Whether you're processing small batches of specialized components or high-volume production parts, our expertise ensures you get the right balance of cost, quality, and performance.

We understand that lab equipment demands precision and reliability. Let us help you optimize your carburizing process to enhance durability and performance while managing costs effectively.

Contact KINTEK today for a personalized consultation and quote – and let's discuss how our carburizing solutions can meet your specific laboratory requirements.

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vertical Laboratory Tube Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What are the disadvantages of quenching? Managing the Risks of Distortion and Cracking

- What role does a precision laboratory oven play in the hydrothermal synthesis of copper sulfate nanocrystals?

- What materials are used in high temperature brazing? Joining Superalloys, Ceramics & More

- Why use a vacuum drying oven for LAGP pellets? Secure High Performance for All-Solid-State Batteries

- What is the difference between annealing tempering and quenching? Master Metal Hardness and Toughness

- What is the purpose of flux in brazing? Ensure Strong, Clean Joints Every Time

- What role does a high-precision tempering furnace play in 42CrMo4 steel treatment? Optimize Strength and Toughness

- What is the secondary melting process? Achieve Superior Metal Purity for Critical Applications