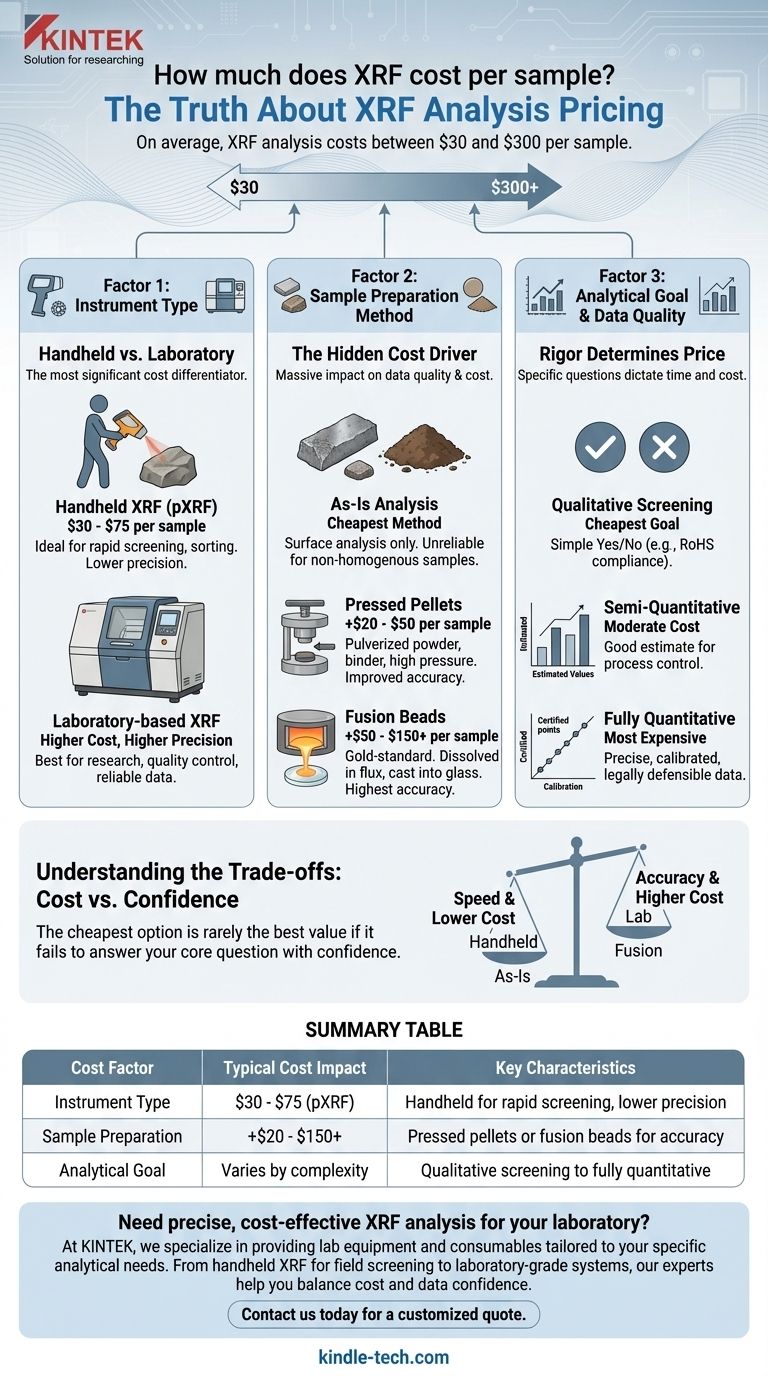

On average, XRF analysis costs between $30 and $300 per sample. This wide range exists because the final price is not for a single, uniform service. The cost is directly determined by the type of XRF instrument used (portable vs. lab-based), the complexity of sample preparation required, and the level of analytical precision your project demands.

The core takeaway is that the cost of XRF is a direct reflection of the quality and complexity of the data you require. The cheapest option is rarely the best value if it fails to answer your core scientific or business question with sufficient confidence.

The Three Core Factors Driving XRF Costs

To accurately budget for XRF analysis, you must understand how the service is priced. The cost is not arbitrary; it's a function of the labor, equipment, and consumables needed to meet your specific analytical goal.

Factor 1: Instrument Type (Handheld vs. Laboratory)

The most significant cost differentiator is the instrument itself.

Handheld XRF (pXRF) is the fastest and most affordable option, typically ranging from $30 to $75 per sample. It's ideal for rapid screening, sorting, and semi-quantitative work where portability is key and a high degree of precision is not the primary goal.

Laboratory-based XRF (WDXRF or EDXRF) is more expensive but provides significantly higher precision and accuracy. This is the choice for research, quality control, and any application where data must be highly reliable and defensible.

Factor 2: Sample Preparation Method

How a sample is prepared before analysis has a massive impact on both data quality and cost. This is often the most significant variable in laboratory-based analysis.

"As-Is" Analysis is the cheapest method. The instrument, often a handheld XRF, analyzes the material's surface directly. This is suitable for homogenous samples like metal alloys but is unreliable for soils, rocks, or powders.

Pressed Pellets are the mid-range option, adding $20 to $50 per sample in labor and consumables. The sample is pulverized into a fine powder, mixed with a binder, and pressed into a dense pellet. This creates a uniform surface, dramatically improving accuracy for many sample types.

Fusion Beads are the gold-standard and most expensive method, often adding $50 to $150+ per sample. The sample is dissolved in a molten lithium borate flux and cast into a perfect glass disc. This eliminates inconsistencies related to particle size and mineralogy, providing the highest possible accuracy for complex materials like rocks, ores, and ceramics.

Factor 3: Analytical Goal & Data Quality

The specific question you need to answer dictates the level of rigor, calibration, and time required for the analysis.

Qualitative Screening is the most basic and cheapest goal. It answers a simple "yes/no" question, such as "Does this plastic contain lead?" This is common for compliance testing (e.g., RoHS).

Semi-Quantitative Analysis provides a good estimate of elemental concentrations. It's more rigorous than a simple screening but lacks the full calibration of a high-precision analysis. This is often sufficient for process control or exploratory work.

Fully Quantitative Analysis is the most expensive and time-consuming. It requires running multiple certified reference materials to create a precise calibration curve for your specific material type, delivering the most accurate and legally defensible data possible.

Understanding the Trade-offs: Cost vs. Confidence

Choosing an XRF analysis method is a balancing act. Opting for the cheapest path without understanding the implications can lead to useless data, wasting your entire investment.

The Speed vs. Accuracy Dilemma

Handheld XRF provides answers in seconds, making it invaluable for field sorting. However, that speed comes at the cost of precision. Lab-based fusion analysis can take hours or days but delivers data you can base high-stakes decisions on.

The Hidden Cost of Poor Preparation

Saving money by skipping proper sample preparation is a false economy. Analyzing a non-homogenous soil sample "as-is" with a pXRF will produce data that is, at best, a rough estimate and, at worst, completely misleading. The money spent on the analysis is wasted if the results cannot be trusted.

Volume Discounts and Setup Fees

Commercial labs operate on economies of scale. Analyzing a single sample is inefficient and will often incur a high minimum charge or setup fee. The per-sample cost can drop significantly when submitting a large batch (e.g., 50 or more samples) because the cost of calibration and setup is spread across the entire job.

Making the Right Choice for Your Goal

Select the XRF method that directly aligns with the confidence you need in your results.

- If your primary focus is rapid field sorting or screening (e.g., scrap metal, RoHS compliance): A handheld XRF provides the most cost-effective path for immediate pass/fail decisions.

- If your primary focus is quality control of homogenous powders or solids: Lab-based XRF with pressed pellet preparation offers the best balance of reliable quantitative data and moderate cost.

- If your primary focus is high-accuracy research or geological exploration: Lab-based XRF using fusion beads is non-negotiable, as the higher cost is required for scientifically or legally defensible data.

Ultimately, understanding these factors allows you to invest wisely, paying only for the data quality your specific goal requires.

Summary Table:

| Cost Factor | Typical Cost Impact | Key Characteristics |

|---|---|---|

| Instrument Type | $30 - $75 (pXRF) | Handheld for rapid screening, lower precision |

| Sample Preparation | +$20 - $150+ | Pressed pellets or fusion beads for accuracy |

| Analytical Goal | Varies by complexity | Qualitative screening to fully quantitative |

Need precise, cost-effective XRF analysis for your laboratory?

At KINTEK, we specialize in providing lab equipment and consumables tailored to your specific analytical needs. Whether you require handheld XRF for rapid field screening or laboratory-grade systems for high-precision quantitative analysis, our experts can help you select the right solution to balance cost and data confidence.

Contact us today to discuss your project requirements and receive a customized quote. Let KINTEK be your trusted partner in achieving accurate, reliable material analysis results.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What is the maximum sieving deviation permitted? A Guide to ASTM & ISO Precision Limits

- What can be separated by sieving? A Guide to Particle Size Separation for Various Materials

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- What are the advantages and disadvantages of sieve analysis? A Guide to Cost-Effective Particle Sizing

- Which Cannot be separated by sieving? Understanding the Limits of Particle Size Separation