The power of a hydraulic press is defined by two distinct metrics: the system's internal pressure (measured in bar or PSI) and the resulting force it can exert (measured in tons or kilograms). While a specialized dental press might operate at 400 bar to produce 15 tons of force, larger industrial presses can generate thousands of tons, with their internal pressure ratings varying based on design.

The most important concept to understand is that a press's output force is the true measure of its power. This force is a product of the hydraulic system's pressure and the size of its piston, meaning a press with lower pressure but a larger piston can be more powerful than one with higher pressure and a smaller piston.

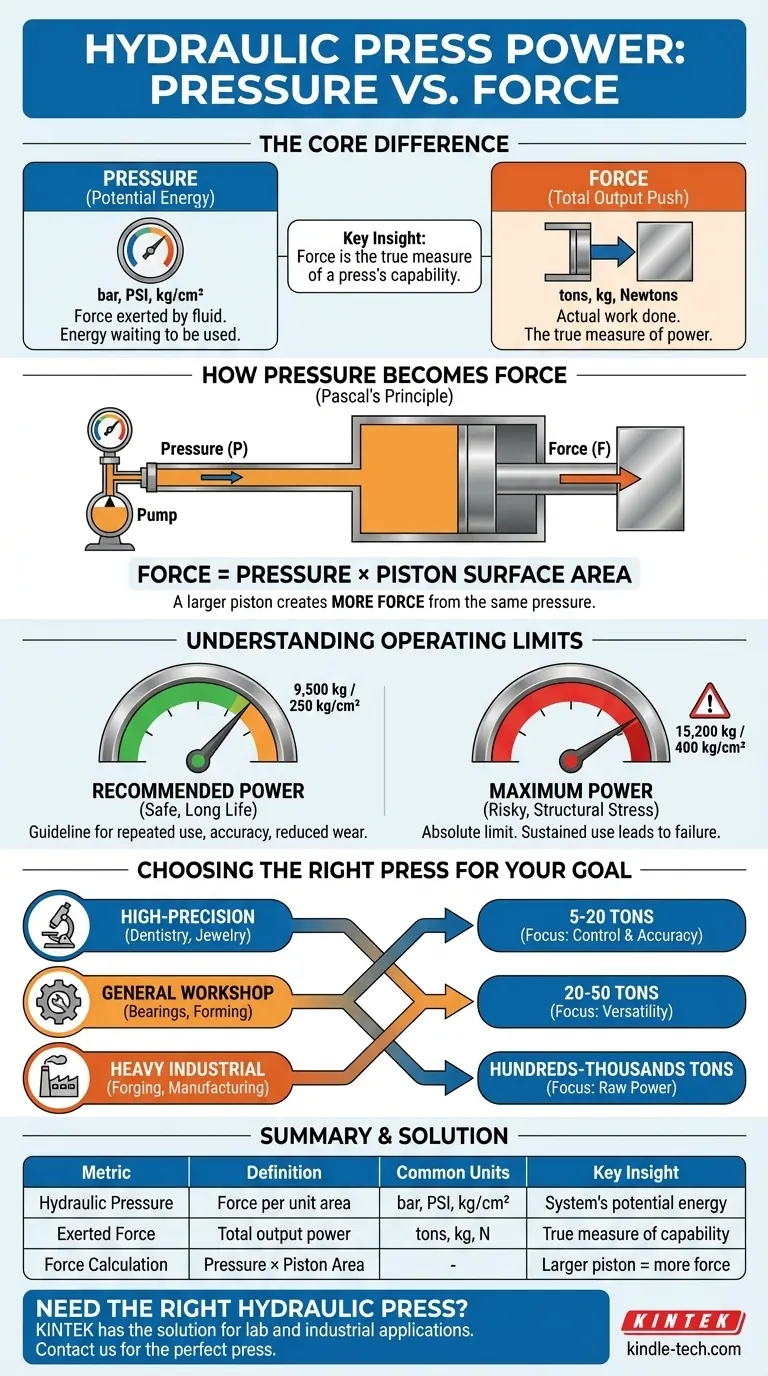

The Key Difference: Pressure vs. Force

Many people use the terms "pressure" and "force" interchangeably, but for a hydraulic press, they are fundamentally different. Understanding this distinction is the key to evaluating a machine's true capability.

What is Hydraulic Pressure?

Pressure is the amount of force exerted by the hydraulic fluid within the enclosed system. It is typically measured in bar, pounds per square inch (PSI), or kilograms per square centimeter (kg/cm²). Think of this as the system's "potential" – it's the energy waiting to be used. A system rated for 400 bar, like the dental press in the example, can safely contain fluid at that high pressure.

What is Exerted Force?

Force is the total output power, or "push," that the press applies to an object. It is measured in kilograms (kg), Newtons (N), or tons. This is the number that tells you how much work the machine can actually do. The 15,000 kg (approximately 15 tons) figure is the press's force rating.

How Pressure Becomes Force

The magic of a hydraulic press comes from Pascal's Principle. A pump creates pressure in the hydraulic fluid, and that pressure acts on a large piston. The machine's final output force is calculated by multiplying the system's pressure by the surface area of the piston. This is why a massive industrial press can achieve immense force without necessarily having astronomically higher fluid pressure than a smaller one—it uses a much larger piston.

Understanding the Trade-offs: Maximum vs. Recommended Power

It's critical to distinguish between what a machine can do and what it should do for sustained, reliable operation. Manufacturers provide two key ratings for this reason.

Maximum Allowed Power

This is the absolute limit the press is designed to handle without immediate structural failure. In the example, this is 15,200 kg of force (at 400 kg/cm² pressure). Operating at this level places extreme stress on the frame, seals, and hydraulic components.

Recommended Operating Power

This is the manufacturer's guideline for normal, repeated use. The example's recommended power is 9,500 kg (at 250 kg/cm² pressure). Running the press at or below this level ensures a longer operational life, maintains accuracy, and significantly reduces the risk of wear and tear or catastrophic failure. Consistently pushing a press to its maximum limit is a recipe for premature breakdown.

Making the Right Choice for Your Goal

When selecting or evaluating a hydraulic press, your focus should be on the final output force required for your specific task.

- If your primary focus is on specialized, high-precision tasks (like dentistry or jewelry): A smaller press with a force rating of 5 to 20 tons is often sufficient, where control and accuracy are more important than raw power.

- If your primary focus is on general workshop tasks (like pressing bearings or forming small parts): A press in the 20 to 50-ton range provides the versatility needed for most fabrication and repair jobs.

- If your primary focus is on heavy industrial applications (like forging or large-scale manufacturing): You will need a press rated for hundreds or even thousands of tons, where the machine's force is the single most critical specification.

Ultimately, understanding that system pressure enables force, but does not solely define it, empowers you to select the right tool for the job.

Summary Table:

| Metric | Definition | Common Units | Key Insight |

|---|---|---|---|

| Hydraulic Pressure | Force per unit area of the fluid | bar, PSI, kg/cm² | The system's potential energy |

| Exerted Force | Total output power on an object | tons, kg, Newtons | The true measure of a press's capability |

| Force Calculation | Pressure × Piston Surface Area | - | A larger piston can create more force from the same pressure |

Need the Right Hydraulic Press for Your Lab or Workshop?

Whether you require a compact, high-precision press for delicate tasks or a powerful industrial model for heavy-duty applications, KINTEK has the solution. Our expertise in lab equipment ensures you get a hydraulic press that delivers the exact force and reliability you need.

Contact KINTEK today to discuss your requirements and let our specialists help you select the perfect press for your workflow.

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- What are the methods of cooling hydraulic system? Prevent Overheating with Passive & Active Cooling

- What is the XRF method of preparation? Ensure Accurate Elemental Analysis with Proper Sample Prep

- What is the cake thickness from a filter press? Optimize Your Filtration Cycle & Efficiency

- What metal is a hydraulic press made of? The Critical Role of High-Strength Steel

- How do a pelletizing die and a laboratory hydraulic press contribute to magnesium pellet formation? Optimize Your Lab.

- Why KBr is used in the KBr pellet method? The Ideal Matrix for Clear IR Spectroscopy

- What is the necessity of using a laboratory hydraulic press for RDF TGA? Optimize Your Thermal Analysis Accuracy

- What are the samples for XRF analysis? A Guide to Preparing Solids, Powders, and Liquids