Properly maintaining electrolytic cell electrodes involves a disciplined cycle of inspection, careful handling, immediate post-experiment cleaning, and correct storage to prevent physical damage, chemical contamination, and corrosion. This routine is essential for ensuring both the accuracy of your results and the longevity of your equipment.

The core principle of electrode maintenance is preventative care. Rather than reacting to poor performance, a systematic approach focused on preserving the electrode's physical and chemical integrity before, during, and after each use will guarantee reliable and repeatable outcomes.

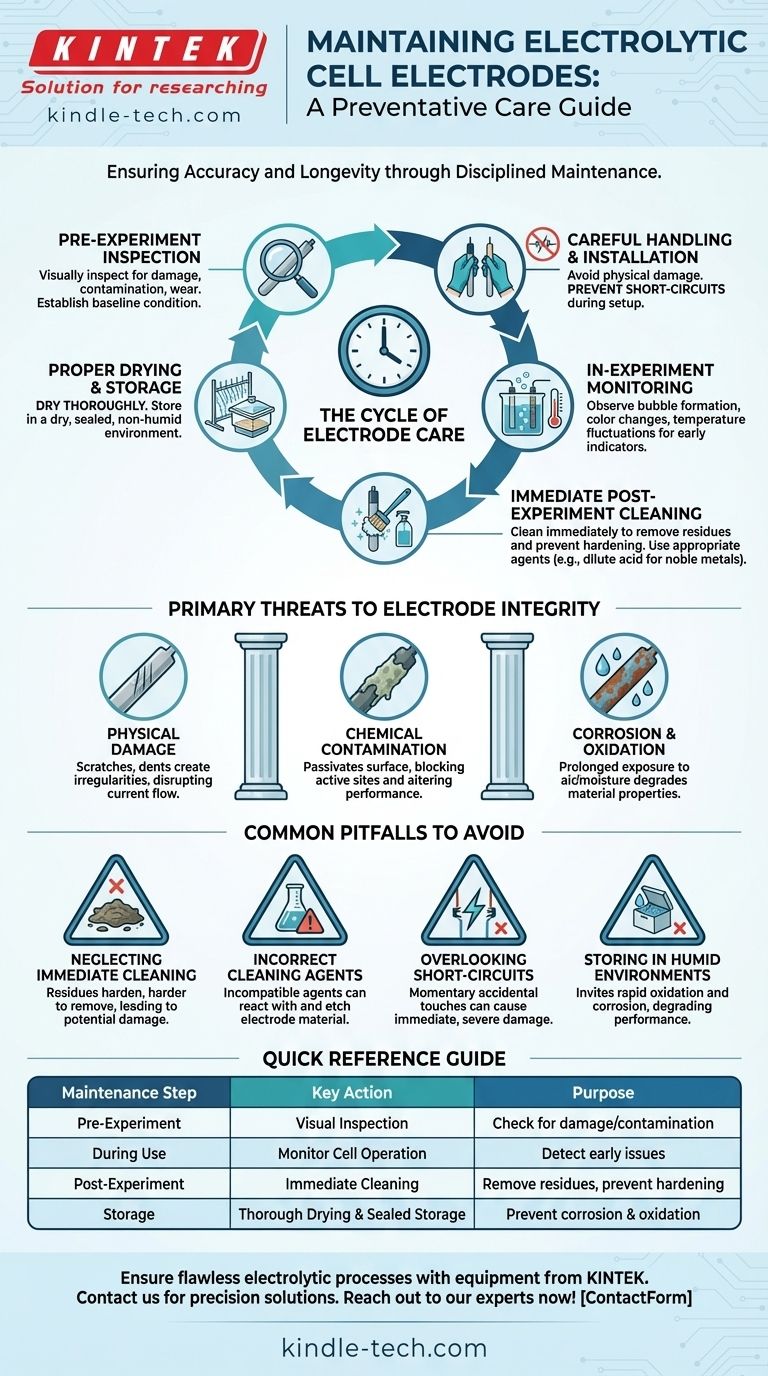

The Maintenance Protocol: A Step-by-Step Guide

Effective electrode care is not a single action but a continuous process. Integrating these steps into your standard operating procedure is the most effective way to protect your investment.

Pre-Experiment Inspection

Before every use, visually inspect the electrode surfaces. Look for any signs of pre-existing wear, corrosion, deformation, or contamination from previous experiments. This establishes a baseline for the electrode's condition.

Careful Handling and Installation

Electrodes are precision instruments. Avoid collisions or scratching the active surfaces, as physical damage can alter current distribution and reaction kinetics.

Crucially, you must prevent the electrodes from short-circuiting during installation. A short circuit will generate an extremely large current, which can cause immediate and irreversible damage to the electrodes and the cell.

In-Experiment Monitoring

During operation, closely monitor the electrolytic cell. Observe for consistent bubble formation, unexpected color changes in the electrolyte, or significant temperature fluctuations. These are early indicators of potential issues with the reaction or electrode performance.

Post-Experiment Cleaning

Clean the electrodes and reaction vessel immediately after each experiment. This prevents reaction products and residues from drying and hardening on the surface, which makes them much more difficult to remove later.

Use an appropriate cleaning agent to remove dirt and oxides. For noble metal electrodes like platinum, a common and effective method is to soak them in a dilute acid (e.g., 1M nitric acid), followed by a thorough rinse with deionized water.

Proper Drying and Storage

After cleaning, the electrodes and vessel must be dried thoroughly. Moisture is a primary catalyst for corrosion and oxidation.

Store the dried components in a dry, non-humid environment. For long-term storage, pour the electrolyte out into a separate, sealed container and ensure the cell and electrodes are completely dry before sealing and storing them.

Understanding the Primary Threats to Electrode Integrity

The maintenance protocol is designed to mitigate three primary threats: physical damage, chemical contamination, and environmental degradation.

Physical Damage

Scratches, dents, or deformations create irregularities on the electrode surface. This disrupts the uniform flow of current and can create localized "hot spots" that lead to inconsistent results and accelerated electrode wear.

Chemical Contamination

Residue from previous reactions can "passivate" the electrode surface. This contamination effectively blocks active sites, reducing the electrode's efficiency and altering its electrochemical behavior.

Corrosion and Oxidation

Prolonged exposure to air and moisture will degrade most electrode materials. This chemical change alters the fundamental properties of the electrode, leading to performance decline and eventual failure. This is why proper drying and storage are non-negotiable.

Common Pitfalls to Avoid

Even with a protocol, simple mistakes can undermine your efforts and lead to costly damage.

Neglecting Immediate Cleaning

Allowing residues to build up makes them significantly harder to remove. This often requires more aggressive cleaning methods that can inadvertently scratch or damage the electrode surface.

Using Incorrect Cleaning Agents

Using a cleaner that is chemically incompatible with your electrode material can cause more harm than good. Always verify that your cleaning agent will not react with or etch the electrode itself.

Overlooking Short-Circuits

A momentary accidental touch between electrodes during setup can be catastrophic. This is the most common cause of sudden, severe damage and must be consciously avoided.

Storing in a Humid Environment

Storing electrodes in an open or humid lab environment is a direct invitation for oxidation and corrosion. This slow, silent damage will steadily degrade performance over time.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your operational tempo and objectives.

- If your primary focus is routine experimental accuracy: Make pre- and post-use inspection and cleaning an unbreakable habit.

- If your primary focus is long-term storage and asset preservation: Prioritize removing the electrolyte, thoroughly drying all components, and storing them in a sealed, non-humid environment.

- If your primary focus is preventing catastrophic failure: Emphasize careful handling to avoid physical damage and, above all, prevent short-circuiting during installation.

By treating electrode maintenance as an integral part of the scientific process, you ensure the reliability of your data and the longevity of your critical equipment.

Summary Table:

| Maintenance Step | Key Action | Purpose |

|---|---|---|

| Pre-Experiment | Visual Inspection | Check for damage/contamination |

| During Use | Monitor Cell Operation | Detect early issues (bubbles, temperature) |

| Post-Experiment | Immediate Cleaning | Remove residues and prevent hardening |

| Storage | Thorough Drying & Sealed Storage | Prevent corrosion and oxidation |

Ensure your lab's electrolytic processes run flawlessly with equipment from KINTEK. Proper maintenance is key, but it starts with reliable lab equipment and consumables. Our expertise supports your laboratory's needs for precision and durability. Contact us today to find the right solutions for your experiments and to learn more about maximizing your equipment's performance. Reach out to our experts now!

Visual Guide

Related Products

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Benchtop Laboratory Freeze Dryer for Lab Use

People Also Ask

- What is the precaution regarding temperature when using an all-PTFE electrolytic cell? Essential Thermal Safety Tips

- What are the primary functions of a high-performance electrolytic cell in the eCO2R process? Optimize Your Lab Results

- Why is the design of a high-airtightness H-type electrolytic cell critical? Ensure CO2RR Product Fidelity

- What are the technical advantages of a three-electrode configuration in PEC? Achieve Precise Catalyst Characterization

- What is the primary role of a three-electrode electrolytic cell system? Achieve Precision in Semiconductor Oxidation