The thickness of a pellet mill die is not a single, fixed number. Instead, it is a critical engineering variable that changes based on the raw material being processed, the desired final pellet quality, and the specific design of the pellet mill itself. The "total thickness" provides the structural strength needed to withstand immense pressure during operation.

The crucial insight is that absolute die thickness is less important than its relationship to the die's hole diameter. This ratio, known as the compression ratio, is what truly determines the quality, density, and durability of the final pellets.

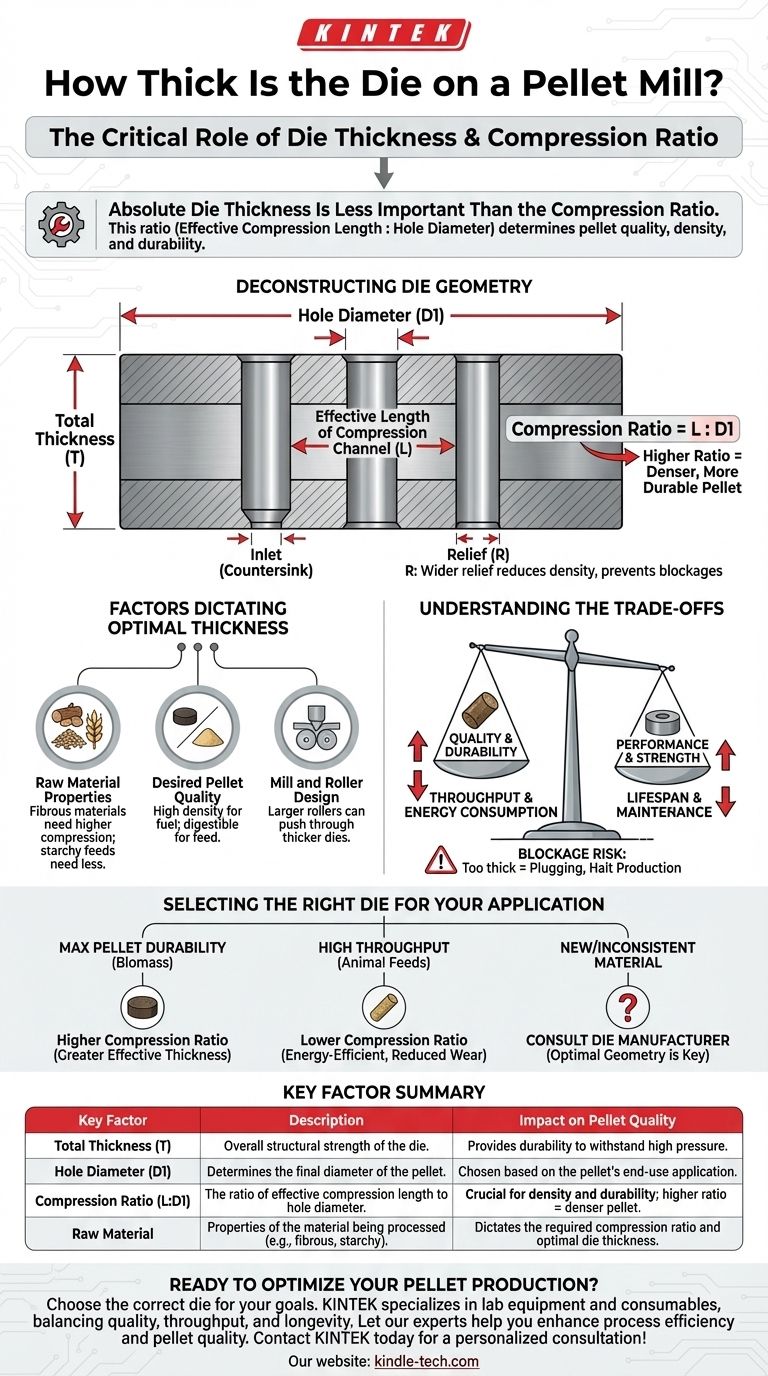

Deconstructing Die Geometry

To understand die thickness, you must look at it as one part of a system of critical dimensions. Each feature serves a specific purpose in transforming loose material into a dense, uniform pellet.

Total Thickness (T)

This is the overall measurement of the die from face to face. Its primary function is to provide the necessary structural mass and strength to prevent the die from breaking or deforming under the extreme pressures of the pelleting process.

Hole Diameter (D1)

This dimension directly determines the final diameter of the pellet. It is the starting point for all other die calculations and is chosen based on the end-use application, from small aquatic feeds to larger biomass fuel pellets.

The Compression Ratio

This is the most critical factor for pellet quality. It is the ratio of the effective length of the compression channel to the hole diameter (D1). A higher ratio means the material is compressed for longer, resulting in a denser, more durable pellet. The die's thickness is the primary component of this effective length.

Inlet Depth and Relief (R)

The inlet is a countersink on the entry side of the hole that helps guide raw material into the compression channel. The relief (R) is a slight widening of the hole on the exit side. A smaller relief increases pellet density, while a larger relief makes it easier for the pellet to exit, reducing the risk of blockages but potentially lowering compactness.

Factors That Dictate Optimal Die Thickness

The ideal die thickness is a carefully balanced calculation based on several interconnected factors. A die that is perfect for one material will be inefficient or ineffective for another.

Raw Material Properties

Different materials have unique compression characteristics. Fibrous materials like softwood may require a die with a higher compression ratio (and thus greater effective thickness) to create a durable pellet. In contrast, starchy feed grains may require less compression.

Desired Pellet Quality

The end goal for the pellet dictates the die design. If the priority is creating extremely hard, high-density fuel pucks, a die with a very high compression ratio is necessary. For softer animal feed that needs to be digestible, a lower ratio is preferable.

Mill and Roller Design

The power of the pellet mill and the size of its rollers influence the choice of die. As the references note, larger diameter rollers have a greater "grabbing force" and can push material through thicker dies more effectively, enabling higher compression and potentially greater throughput.

Understanding the Trade-offs

Selecting a die thickness is an exercise in balancing competing priorities. Optimizing for one factor often means compromising on another.

Quality vs. Throughput

Increasing the die thickness to achieve a higher compression ratio generally improves pellet density and durability. However, it also increases resistance, which can slow down the production rate (throughput) and significantly increase energy consumption per ton.

Performance vs. Lifespan

While a thick die is structurally strong, forcing material through a high-compression channel generates immense friction and stress. This accelerates wear on both the die and the press rollers, potentially increasing maintenance costs and downtime.

The Risk of Blockages

Using a die that is too thick for a specific material is a primary cause of blockages. If the pressure generated by the rollers is insufficient to extrude the compressed material, the die holes will plug, bringing production to a halt.

Selecting the Right Die for Your Application

Choosing the correct die specification is essential for efficient and cost-effective operation. The decision should always be based on your specific operational goals.

- If your primary focus is maximum pellet durability and density (e.g., biomass fuel): You will need a die with a higher compression ratio, meaning a greater effective thickness relative to its hole diameter.

- If your primary focus is high throughput for easily compressed materials (e.g., certain animal feeds): A die with a lower compression ratio will be more energy-efficient and productive, reducing wear on your equipment.

- If you are processing a new or inconsistent raw material: It is critical to consult directly with the die manufacturer to determine the optimal geometry, as a generic, off-the-shelf thickness will likely be inefficient.

Ultimately, the correct die thickness is a precisely engineered specification that balances final pellet quality with your overall operational efficiency.

Summary Table:

| Key Factor | Description | Impact on Pellet Quality |

|---|---|---|

| Total Thickness (T) | Overall structural strength of the die. | Provides durability to withstand high pressure. |

| Hole Diameter (D1) | Determines the final diameter of the pellet. | Chosen based on the pellet's end-use application. |

| Compression Ratio (L:D1) | The ratio of effective compression length to hole diameter. | Crucial for density and durability; higher ratio = denser pellet. |

| Raw Material | Properties of the material being processed (e.g., fibrous, starchy). | Dictates the required compression ratio and optimal die thickness. |

Ready to Optimize Your Pellet Production?

Choosing the correct die thickness and compression ratio is essential for achieving your specific goals, whether it's maximum pellet durability for biomass fuel or high throughput for animal feed. The wrong die can lead to poor quality, low efficiency, and costly blockages.

KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories and R&D facilities. Our expertise ensures you get the right specifications for your pellet mill die, balancing quality, throughput, and equipment longevity.

Let our experts help you enhance your process efficiency and pellet quality. Contact KINTELK today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

People Also Ask

- How do laboratory hydraulic presses facilitate biomass pelletization? Optimize Biofuel Density and Prevent Slagging

- Why is a laboratory hydraulic press used for Li3V2(PO4)3 pellets? Optimize Solid-State Sintering for Li-ion Materials

- What are the advantages of using a laboratory manual hydraulic pellet press for FTIR? Enhance Your Spectral Data

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the function of a laboratory hydraulic press during the fabrication of Beta-Al2O3 solid electrolyte pellets?