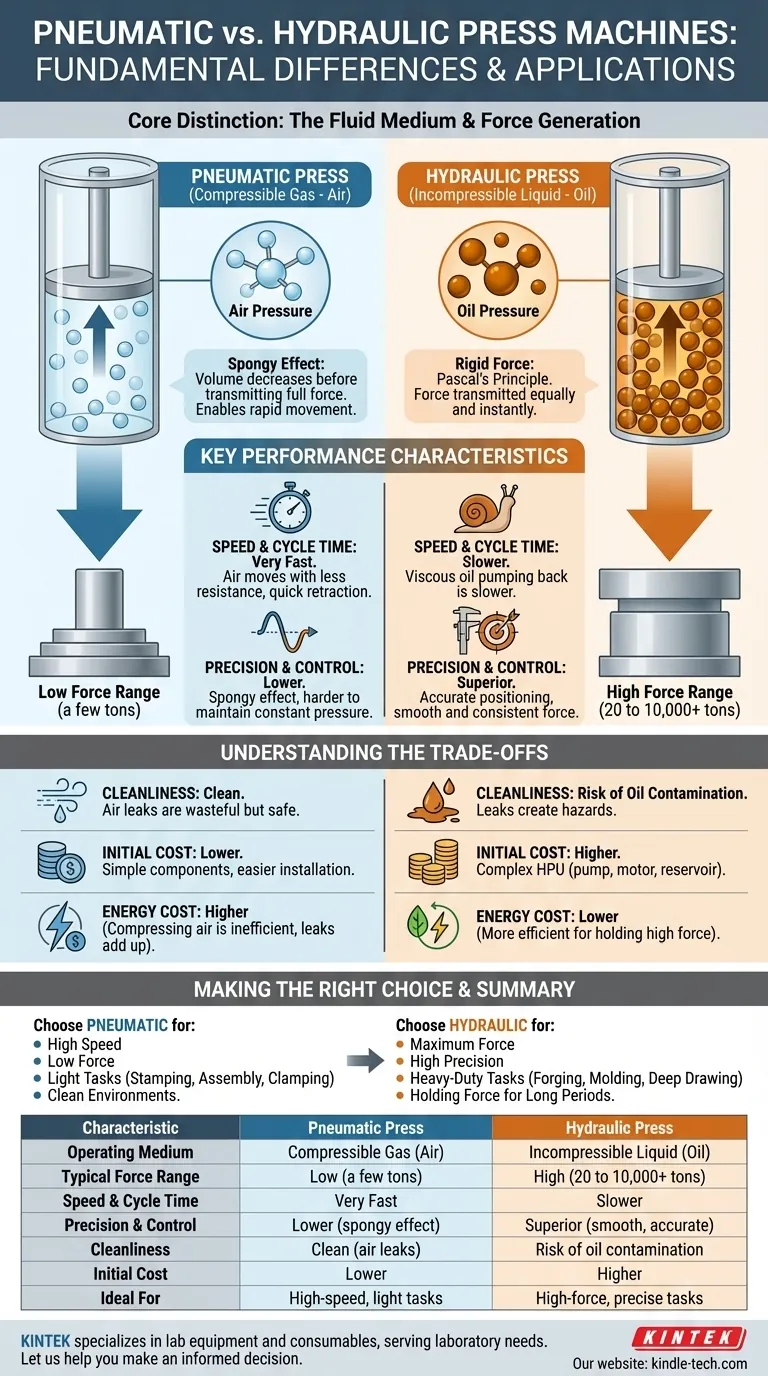

No, a pneumatic press and a hydraulic press are fundamentally different technologies. While both use a fluid to generate force, the nature of that fluid dictates their capabilities and applications. Hydraulic presses use an incompressible liquid, typically oil, to transmit immense force, whereas pneumatic presses use a compressible gas, like air, for faster, lower-force operations.

The core distinction lies in the medium: hydraulics use incompressible liquid for high force and precision, while pneumatics use compressible gas for high speed and cost-effectiveness in lighter applications. Choosing the right press means understanding this foundational trade-off.

The Core Difference: How They Generate Force

The behavior of each press type is a direct result of the physical properties of the fluid it uses. This single difference explains nearly all the variations in performance, cost, and complexity.

Hydraulic Presses: Incompressible Liquid Power

A hydraulic system operates on Pascal's Principle, which states that pressure applied to a confined, incompressible fluid is transmitted equally in all directions.

Because the oil cannot be compressed, any force applied by the pump is instantly converted into work at the cylinder. This allows hydraulic presses to generate extremely high, consistent, and controllable forces, often reaching thousands of tons.

Pneumatic Presses: Compressible Gas Power

Pneumatic systems use compressed air. Unlike oil, air is a compressible gas. When you apply pressure, the air's volume decreases before it begins to transmit the full force.

This compressibility creates a "spongy" effect, meaning the force is not applied as rigidly. However, it also allows for very rapid movement, as air can be quickly directed into and exhausted from the cylinder.

Comparing Key Performance Characteristics

Understanding the physics allows us to compare these two press types across the metrics that matter most in an industrial setting.

Force and Tonnage

Hydraulic presses are the clear winners for high-force applications. Their use of incompressible fluid allows them to easily achieve forces from 20 tons to over 10,000 tons, making them ideal for heavy-duty metal forming, molding, and forging.

Pneumatic presses operate in a much lower force range. They are typically used for tasks requiring just a few tons of force, such as clamping, stamping, crimping, and light assembly.

Speed and Cycle Time

Pneumatic presses are generally faster. Air moves with less resistance than oil and can be rapidly exhausted directly into the atmosphere, allowing for quick cylinder retraction and very high cycle rates.

Hydraulic systems are slower because the viscous oil must be pumped back to a reservoir. While advanced hydraulics can be fast, they cannot typically match the raw speed of a simple pneumatic system for light tasks.

Precision and Control

Hydraulics offer superior control and precision. The incompressible nature of oil means the press ram can be positioned with extreme accuracy and will hold its position without fluctuation. The force can be applied smoothly and consistently throughout the entire stroke.

Pneumatic presses are harder to control with precision due to the "springiness" of compressed air. The force can fluctuate as the air compresses, making them less suitable for tasks that require a specific, constant pressure through the stroke.

Understanding the Trade-offs

Choosing a press is not just about performance; it's also about managing complexity, cost, and operational realities.

System Cleanliness and Leaks

A major consideration for hydraulic systems is the potential for oil leaks. These leaks can create safety hazards (slip and fall), contaminate products, and require significant cleanup.

Pneumatic systems leak air, which is clean. While an air leak is wasteful and reduces system efficiency, it does not create the contamination or safety issues associated with a hydraulic fluid leak.

Initial Investment and Maintenance

Pneumatic systems are typically less expensive to purchase and install. The components (cylinders, valves, fittings) are simpler and more standardized. They run on a central air compressor, which may already exist in a facility.

Hydraulic systems are more complex and costly. They require a dedicated hydraulic power unit (HPU) which includes a motor, pump, reservoir, filters, and coolers. Maintenance is also more involved, requiring fluid monitoring and filter changes.

Energy and Operational Cost

Compressed air is often called the "fourth utility," but it is an expensive one. Compressing air is an inefficient process that generates significant waste heat. Constant air leaks can dramatically increase energy costs.

Hydraulic systems are generally more energy-efficient for high-force applications, especially when holding a load under pressure for an extended period. The pump only needs to run to build pressure, after which it can be maintained with minimal energy input.

Making the Right Choice for Your Application

The decision between pneumatic and hydraulic technology is a direct function of your operational goals.

- If your primary focus is maximum force and precision: A hydraulic press is the correct choice for tasks like deep drawing, plastic molding, or forging.

- If your primary focus is high speed and lower cost for light tasks: A pneumatic press excels at applications like stamping, riveting, clamping, or parts assembly.

- If your primary focus is a clean environment (e.g., food or electronics): A pneumatic press is often the safer, cleaner option due to the risk of hydraulic oil contamination.

- If your primary focus is holding a constant force for long periods: A hydraulic system is more energy-efficient and stable for press-and-hold applications.

By matching the fundamental capabilities of each technology to your specific requirements, you can ensure you are selecting the most effective and efficient tool for the job.

Summary Table:

| Characteristic | Pneumatic Press | Hydraulic Press |

|---|---|---|

| Operating Medium | Compressible Gas (Air) | Incompressible Liquid (Oil) |

| Typical Force Range | Low (a few tons) | High (20 to 10,000+ tons) |

| Speed & Cycle Time | Very Fast | Slower |

| Precision & Control | Lower (spongy effect) | Superior (smooth, accurate) |

| Cleanliness | Clean (air leaks) | Risk of oil contamination |

| Initial Cost | Lower | Higher |

| Ideal For | High-speed, light tasks (clamping, stamping, assembly) | High-force, precise tasks (forging, molding, deep drawing) |

Still Unsure Which Press is Right for Your Lab?

Choosing the correct press technology is critical for the efficiency and success of your operations. The wrong choice can lead to inadequate force, poor precision, or unnecessary costs.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you analyze your specific application requirements—whether it's high-force material testing or high-speed sample preparation—to recommend the perfect press solution.

Let us help you make an informed decision. Contact our technical team today for a personalized consultation and discover how the right press can enhance your lab's productivity and results.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability