Yes, in all practical and engineering contexts, brazing creates a permanent joint. A properly executed brazed joint forms a strong, metallurgical bond that is not designed for disassembly and is intended to last the life of the assembly. The process is fundamentally different from mechanical fastening with bolts or screws.

While a brazed joint is considered permanent and can even be stronger than the metals it joins, its true permanence is defined by its application. It offers a powerful alternative to welding but has distinct limitations, particularly regarding service temperature.

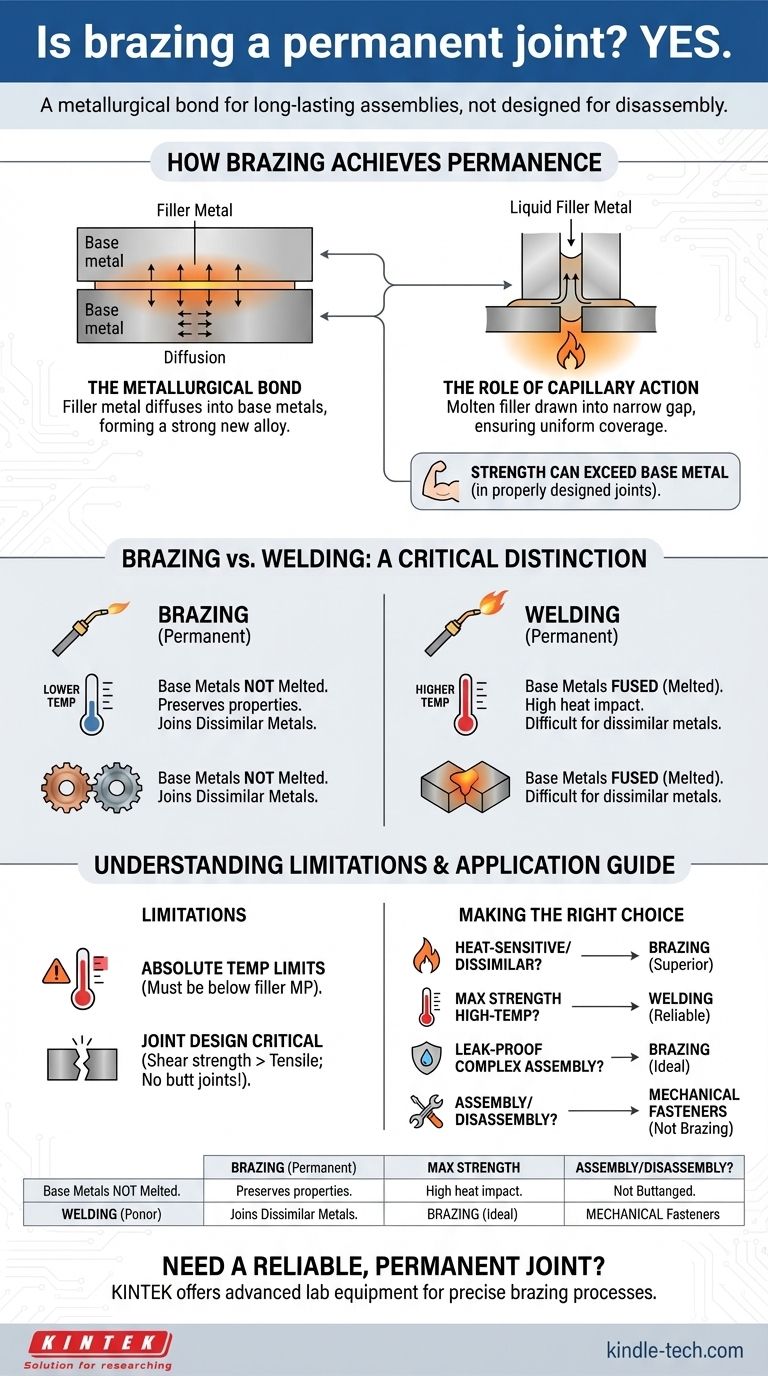

How Brazing Achieves Permanence

The Metallurgical Bond

Brazing is not simply a high-temperature gluing process. It creates a metallurgical bond where the filler metal diffuses slightly into the surface of the base metals, forming a new, strong alloy at the interface.

This is a chemical connection, not a simple mechanical one, which is the source of its strength and permanence.

The Role of Capillary Action

The process works by heating two closely fitted parent metals to a temperature above the melting point of the filler metal, but below the melting point of the parent metals.

The molten filler is then drawn into the gap between the parts by capillary action, ensuring complete and uniform coverage. This is why joint design and cleanliness are so critical.

Strength Can Exceed the Base Metal

A common misconception is that a brazed joint is only as strong as its relatively soft filler metal.

However, in a properly designed joint (like a lap joint with a very thin gap), the filler metal's properties are enhanced by the geometry. This can result in a completed joint that has a tensile strength greater than the base metals themselves.

Brazing vs. Welding: A Critical Distinction

To understand brazing's permanence, it's useful to compare it to welding, the other common method for creating permanent metal joints.

Base Metals Are Not Melted

This is the single most important difference. Welding fuses metals by melting them together, often with a filler. Brazing joins metals without melting them.

Preserving Material Properties

Because brazing occurs at a much lower temperature, it has a minimal thermal impact on the base metals. This is a major advantage when joining materials that have been heat-treated, work-hardened, or have delicate microstructures.

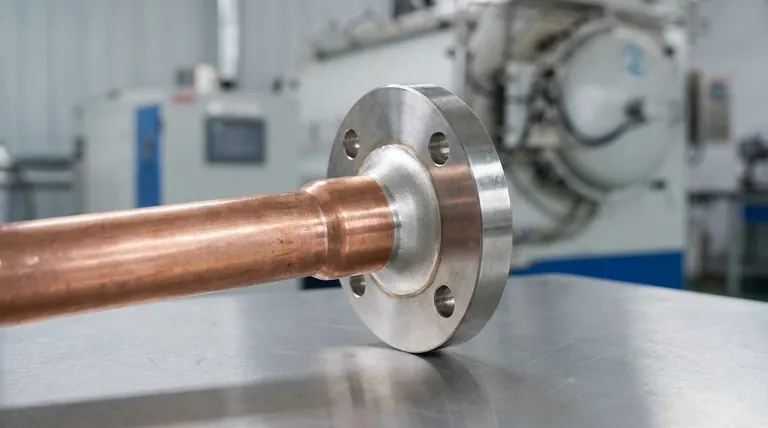

Joining Dissimilar Metals

Brazing excels at joining fundamentally different metals, such as copper to steel or aluminum to copper. This is often extremely difficult or impossible to achieve with conventional welding processes.

Understanding the Trade-offs and Limitations

No joining method is perfect for every situation. Objectivity requires acknowledging brazing's limitations.

Absolute Temperature Limits

A brazed joint's primary weakness is its performance at high temperatures. The service temperature of the assembly must always remain well below the melting point of the filler metal used.

If the joint is exposed to temperatures that approach the filler's melting point, it will rapidly lose all its strength.

Joint Design is Non-Negotiable

Brazing relies heavily on shear strength, not tensile strength. Joints must be designed with an overlapping surface area (like a lap or scarf joint) to maximize strength.

A simple butt joint, where two pieces meet end-to-end, will be inherently weak and is not a suitable application for brazing.

Disassembly is a Repair, Not a Feature

While a brazed joint can technically be taken apart by reheating it until the filler melts, this is a repair or rework procedure. It is not a form of non-destructive disassembly like unbolting a fastener. The process often requires specialized skill and can damage the components.

Making the Right Choice for Your Application

Use these guidelines to determine if brazing is the correct approach for your project.

- If your primary focus is joining heat-sensitive or dissimilar metals: Brazing is almost always the superior choice over welding due to its low-temperature process.

- If your primary focus is maximum strength in a high-temperature environment: Welding is the more reliable method, as it creates a joint from the base metals themselves.

- If your primary focus is creating a leak-proof seal in a complex assembly: Brazing is ideal, as capillary action can draw the filler into tight spaces that are inaccessible to a welding torch.

- If your primary focus is assembly and disassembly: You must use mechanical fasteners; brazing is a permanent joining method.

Choosing the right joining method is about matching the process to the specific demands of the application and its service environment.

Summary Table:

| Feature | Brazing | Welding |

|---|---|---|

| Base Metals Melted? | No | Yes |

| Joint Type | Metallurgical Bond | Fusion Weld |

| Service Temperature | Limited by filler metal | Limited by base metal |

| Ideal For | Dissimilar metals, complex assemblies | High-temperature environments |

| Permanence | Permanent (not designed for disassembly) | Permanent |

Need a reliable, permanent joint for your application?

Brazing offers a superior solution for joining dissimilar or heat-sensitive metals while preserving their integrity. At KINTEK, we specialize in providing the advanced lab equipment and consumables needed for precise brazing processes.

Let our experts help you select the right solution for your laboratory's specific needs. Contact KINTEL today to discuss how we can support your project with durable, high-performance joining solutions.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the physical process of deposition? A Guide to PVD Thin-Film Coating

- What are the advantages and disadvantages of electron beam evaporation? Achieve High-Purity Thin Films

- What XRF Cannot detect? Uncover the Critical Limitations of XRF Analysis

- Why is an ultrasonic cleaner used with ethanol to treat alloy specimens? Ensure Superior Diffusion Bonding Results

- What are the types of annealing? Choose the Right Process for Your Metal's Properties

- What are metal sintering processes? Unlock the Power of Powder Metallurgy

- Why is sputtering more useful for alloy deposition? Achieve Precise Alloy Composition Control

- What precautions should be observed during heat treatment? Essential Safety Protocols for Your Lab