Yes, electron beam (e-beam) assisted evaporation is not only used for metals—it is a cornerstone technology for their deposition. This physical vapor deposition (PVD) method is specifically chosen for its ability to vaporize materials with very high melting points, including many metals and dielectrics that are impossible to process with simpler thermal techniques. Its high degree of control over film thickness and purity makes it indispensable for advanced applications.

E-beam evaporation is the preferred method for depositing high-melting-point metals or when precise control over film thickness and structure is paramount. It overcomes the temperature limitations of simpler thermal evaporation techniques, enabling the use of a wider range of high-performance materials.

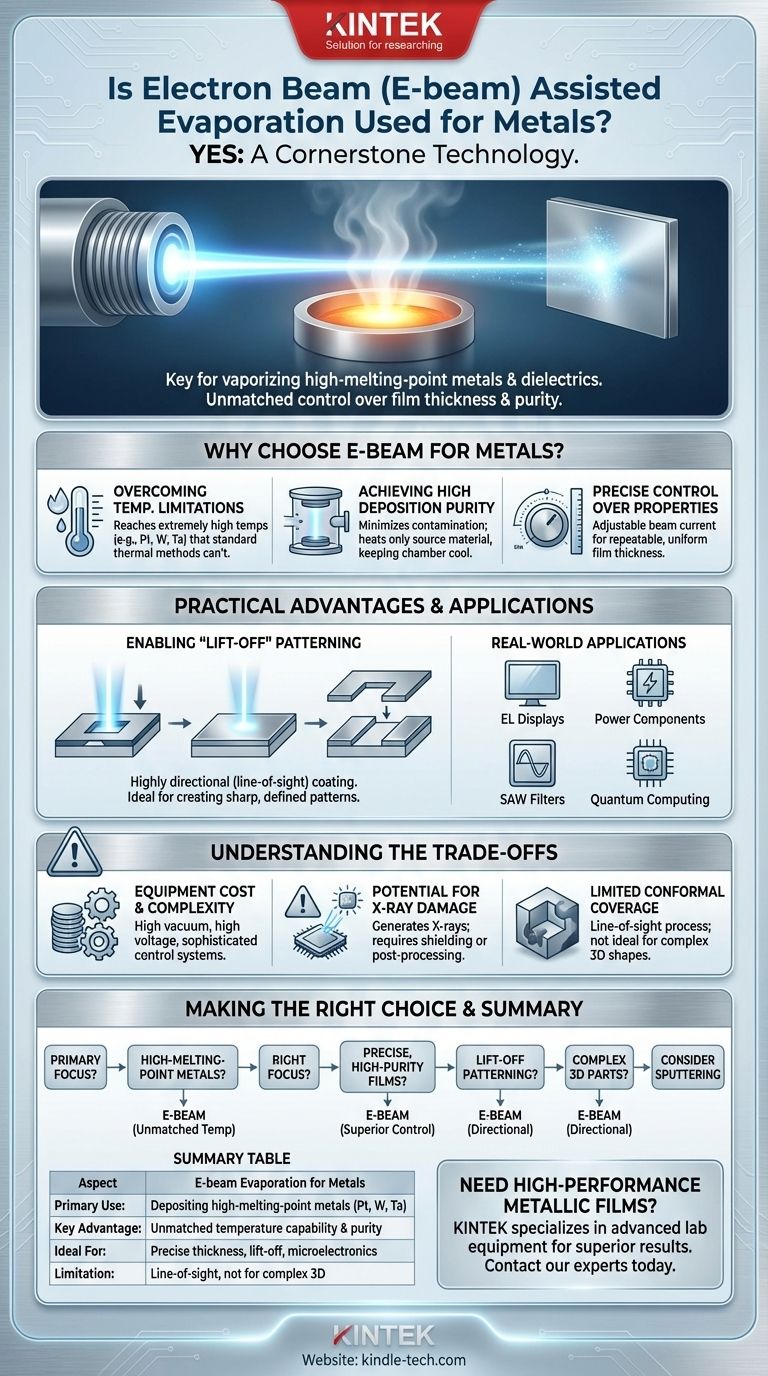

Why Choose E-beam Evaporation for Metals?

The decision to use e-beam evaporation over other methods is driven by distinct technical advantages related to temperature, purity, and control.

Overcoming Temperature Limitations

Many technologically important metals, such as platinum, tungsten, and tantalum, have extremely high evaporation temperatures. Standard thermal evaporation, which uses a resistively heated boat or filament, simply cannot reach these temperatures effectively or without contaminating the film.

The e-beam process uses a high-energy beam of electrons to heat the source material directly and locally. This intense, focused energy can vaporize virtually any material, making it a highly versatile and capable tool.

Achieving High Deposition Purity

Because the electron beam heats only the source material in its crucible, the surrounding vacuum chamber components remain relatively cool. This minimizes outgassing and contamination from the equipment itself.

This results in a much purer deposited film compared to methods where a heating element is in close proximity to the source material.

Gaining Precise Control Over Film Properties

The deposition rate in an e-beam system can be controlled with exceptional precision by adjusting the beam's current. This allows for the creation of films with highly repeatable and uniform thickness, from a few angstroms to many microns.

This level of control is critical in applications like optical coatings and microelectronics, where film thickness directly impacts device performance.

The Practical Advantages of the E-beam Process

Beyond its fundamental capabilities, the nature of the e-beam process yields benefits for specific manufacturing techniques.

Enabling "Lift-Off" Patterning

E-beam evaporation is a line-of-sight process, meaning the evaporated material travels in a straight line from the source to the substrate. This results in a highly directional, or anisotropic, coating.

This property is ideal for a patterning technique called "lift-off," where a mask is applied to the substrate before deposition. The directional coating ensures clean edges with no material deposited on the sidewalls of the mask, allowing for easy removal and the creation of very sharp, well-defined patterns.

Real-World Applications

The precision and material versatility of e-beam evaporation are leveraged across many industries. You can find e-beam deposited metallic films in:

- Organic and inorganic electroluminescent (EL) displays

- Power pack components

- Surface acoustic wave (SAW) filters

- Components for watches and lithium-ion batteries

- Josephson junctions for quantum computing

Understanding the Trade-offs

No technology is without its limitations. Being a trusted advisor means presenting an objective view.

Equipment Complexity and Cost

E-beam evaporators are significantly more complex and expensive than standard thermal evaporators. They require a high-vacuum environment, high-voltage power supplies, and sophisticated control systems, leading to higher initial investment and maintenance costs.

Potential for X-ray Damage

The high-energy electron beam generates X-rays as a byproduct when it strikes the source material. These X-rays can potentially damage sensitive substrates or electronic devices. While often manageable with shielding or post-processing, it is a critical factor for certain applications.

Limited Conformal Coverage

The same line-of-sight property that is an advantage for lift-off is a disadvantage for coating complex, three-dimensional shapes. The process cannot easily coat "shadowed" areas, leading to non-uniform coverage on non-flat surfaces. For such applications, a more conformal technique like sputtering is often preferred.

Making the Right Choice for Your Metal

To determine if e-beam evaporation is the correct approach, consider your primary objective.

- If your primary focus is depositing high-melting-point metals (e.g., platinum, tungsten, titanium): E-beam is often the only practical evaporation method due to its unmatched temperature capabilities.

- If your primary focus is creating precise, high-purity films for electronics or optics: The fine control over deposition rate and the inherently clean process make e-beam a superior choice.

- If your primary focus is patterning using a lift-off process: The directional, line-of-sight deposition of e-beam is perfectly suited for creating sharp, well-defined features.

- If your primary focus is coating complex 3D parts or minimizing equipment cost: You should evaluate alternative methods like sputtering for coverage or standard thermal evaporation for lower-temperature metals.

Ultimately, understanding these capabilities allows you to select e-beam evaporation not just as a method, but as the right tool for achieving high-performance metallic films.

Summary Table:

| Aspect | E-beam Evaporation for Metals |

|---|---|

| Primary Use | Depositing high-melting-point metals (e.g., Pt, W, Ta) |

| Key Advantage | Unmatched temperature capability and high film purity |

| Ideal For | Precise film thickness control, lift-off patterning, microelectronics |

| Limitation | Line-of-sight process; not ideal for complex 3D coatings |

Need to deposit high-performance metallic films with precision and purity? KINTEK specializes in advanced lab equipment, including electron beam evaporation systems, to meet the demanding needs of research and production laboratories. Our solutions are designed to help you achieve superior results with high-melting-point metals and delicate substrates. Contact our experts today to discuss how we can support your specific application and enhance your laboratory's capabilities.

Visual Guide

Related Products

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Tungsten Evaporation Boat for Thin Film Deposition

- Ceramic Evaporation Boat Set Alumina Crucible for Laboratory Use

People Also Ask

- What is the difference between thermal evaporation and magnetron sputtering? Choose the Right PVD Coating Method

- What is the process of thin film evaporation? A Guide to High-Purity PVD Coating

- What is electron beam physical vapor deposition method? A High-Purity Coating Technique for Demanding Applications

- What are the advantages of using a covered ceramic boat as a carrier during the high-temperature sulfidation of tungsten oxide?

- What is the meaning of thermal evaporation? A Guide to Simple, Cost-Effective Thin Film Coating

- How does e-beam evaporation work? A Guide to High-Purity Thin Film Deposition

- What is vacuum thin-film deposition? The Key to Advanced Surface Engineering

- What is thermal evaporation of thin film deposition? A Simple Guide to PVD Coating