For all practical purposes, yes. Induction heating feels instant because it does not waste time heating a middleman, like a gas grate or an electric coil. Instead, it uses an electromagnetic field to generate heat directly and immediately inside the cookware itself, making it the most responsive cooking technology available.

The term "instant heat" describes induction's ability to begin heating your pan the moment it is activated. By eliminating the delay required by traditional methods that must first warm a separate element, this direct-to-pan energy transfer provides unparalleled speed and temperature control.

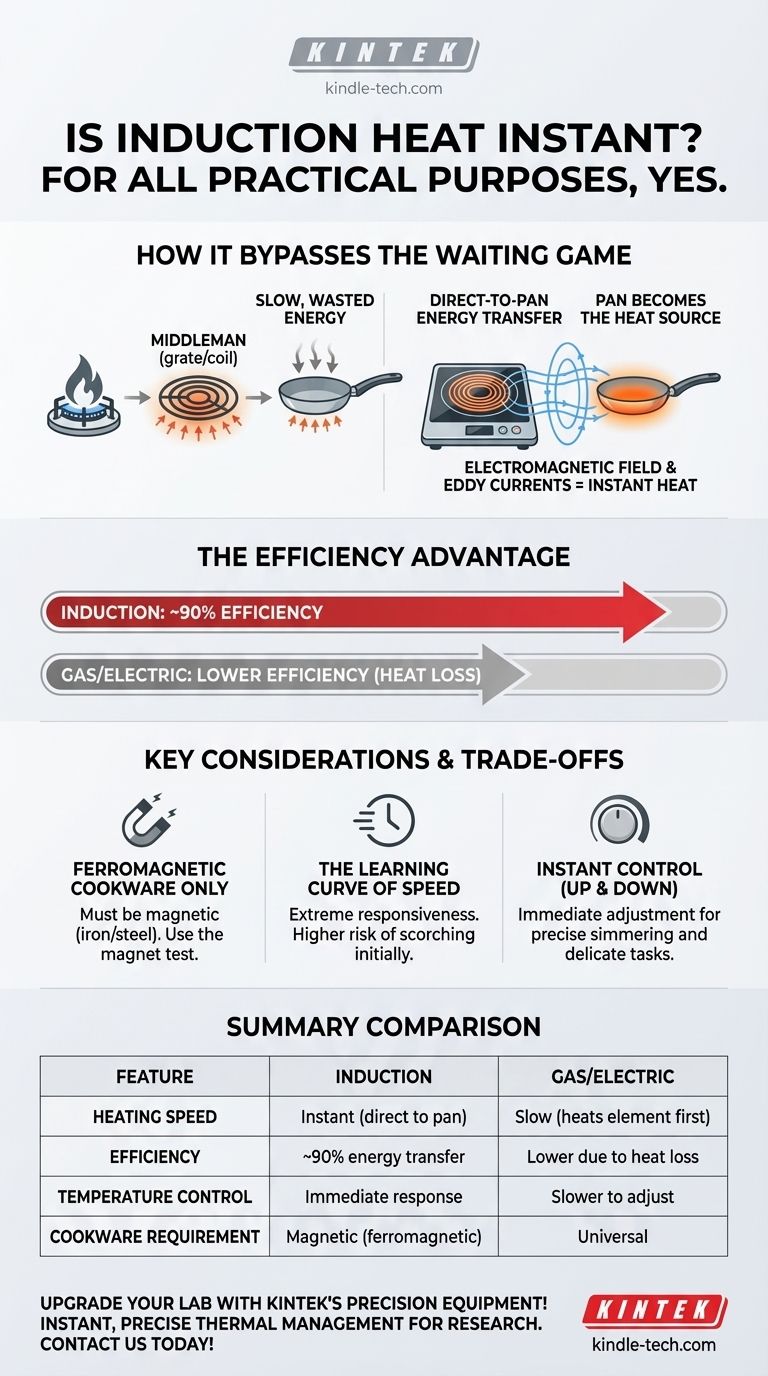

How Induction Bypasses the Waiting Game

The "magic" of induction's speed lies in its unique method of heat generation. It fundamentally changes the relationship between the cooktop, energy, and the cookware.

The Role of Electromagnetism

Beneath the glass surface of an induction cooktop sits a tightly-wound copper coil. When you turn the unit on, an electric current flows through this coil, creating a high-frequency alternating magnetic field.

This field itself is not hot. However, it extends upwards into the base of your pan.

Your Cookware Becomes the Heat Source

When a pan made of a magnetic material (like cast iron or stainless steel) is placed in this field, the field induces tiny, swirling electrical currents within the metal of the pan. This is known as an eddy current.

The pan's natural electrical resistance fights against these currents, and this struggle instantly generates immense heat. Your pan becomes the heater, not the cooktop surface.

No Wasted Energy, No Wasted Time

This process is remarkably efficient. Approximately 90% of the electrical energy is converted directly into heat within your pan.

Compare this to gas or traditional electric, where a significant amount of energy is first used to heat the burner and the surrounding air before it ever begins to heat your pan. Induction skips these slow, wasteful steps entirely.

Understanding the Trade-offs

While the speed is a primary benefit, the technology comes with specific requirements and considerations that differ from traditional cooking methods.

The Critical Cookware Requirement

Induction only works with ferromagnetic cookware. The magnetic field requires a material like iron or magnetic-grade stainless steel to create the heating effect.

Pots and pans made of glass, copper, or aluminum will not work unless they have a specific steel plate bonded to their base. A simple test is to see if a magnet sticks firmly to the bottom of your pan.

The Learning Curve of Speed

The sheer responsiveness of induction can be jarring for new users. Water boils significantly faster, and oils can get to their smoke point in seconds.

This requires a more attentive cooking style initially, as the familiar delays of gas or electric stoves are completely eliminated. The risk of scorching food is higher until you adapt to the speed.

Instant Control in Both Directions

The "instant" nature also applies when you turn the power down or off. The moment you lower the setting, the magnetic field weakens, and heat generation decreases immediately.

This gives you precise control over simmering and delicate sauces that is difficult to achieve on an electric stove that retains heat long after being turned down.

Making the Right Choice for Your Goal

Deciding if induction is right for you depends on what you value most in the cooking process.

- If your primary focus is speed and precision: Induction is the undisputed leader, offering the fastest heating and most responsive temperature control for exacting culinary tasks.

- If your primary focus is compatibility with all cookware: Traditional gas or electric cooktops offer universal compatibility, though they sacrifice the significant speed and efficiency benefits of induction.

- If your primary focus is energy efficiency: Induction's direct heating method makes it the most efficient choice, transferring more energy to the food and wasting less as ambient heat.

Ultimately, understanding this principle of direct, instantaneous heating empowers you to leverage induction's incredible responsiveness for better results in your kitchen.

Summary Table:

| Feature | Induction | Gas/Electric |

|---|---|---|

| Heating Speed | Instant (direct to pan) | Slow (heats element first) |

| Efficiency | ~90% energy transfer | Lower due to heat loss |

| Temperature Control | Immediate response | Slower to adjust |

| Cookware Requirement | Magnetic (ferromagnetic) | Universal |

Upgrade your lab's heating capabilities with KINTEK's precision equipment! Just as induction heating revolutionizes speed and control in the kitchen, our advanced lab furnaces and heaters deliver instant, precise thermal management for your most demanding applications. Whether you need rapid heating for materials testing or exact temperature control for research, KINTEK specializes in reliable, efficient lab equipment tailored to your needs. Contact us today to find the perfect heating solution for your laboratory!

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What is the advantage of induction brazing? Speed vs. Integrity for Your Assembly Needs

- What is the role of a high-frequency induction melting furnace in super duplex stainless steel prep? Achieve Precision

- What are the factors that affect melting? Master Temperature, Pressure & Chemistry for High-Quality Results

- What are the disadvantages of induction melting? Key Limitations in Metallurgy and Operation

- How does vacuum arc melting equipment facilitate Ti-Cr-Al-Nb alloy prep? Precision High-Temp Melting Explained

- What is the difference between resistance furnace and induction furnace? Choose the Right Heating Method for Your Lab

- What is the primary function of a Vacuum Induction Melting Furnace? Achieving Pure Cu-Si Alloy Synthesis

- How hot does a furnace need to be to melt copper? Achieve a Perfect Pour at 1150-1200°C