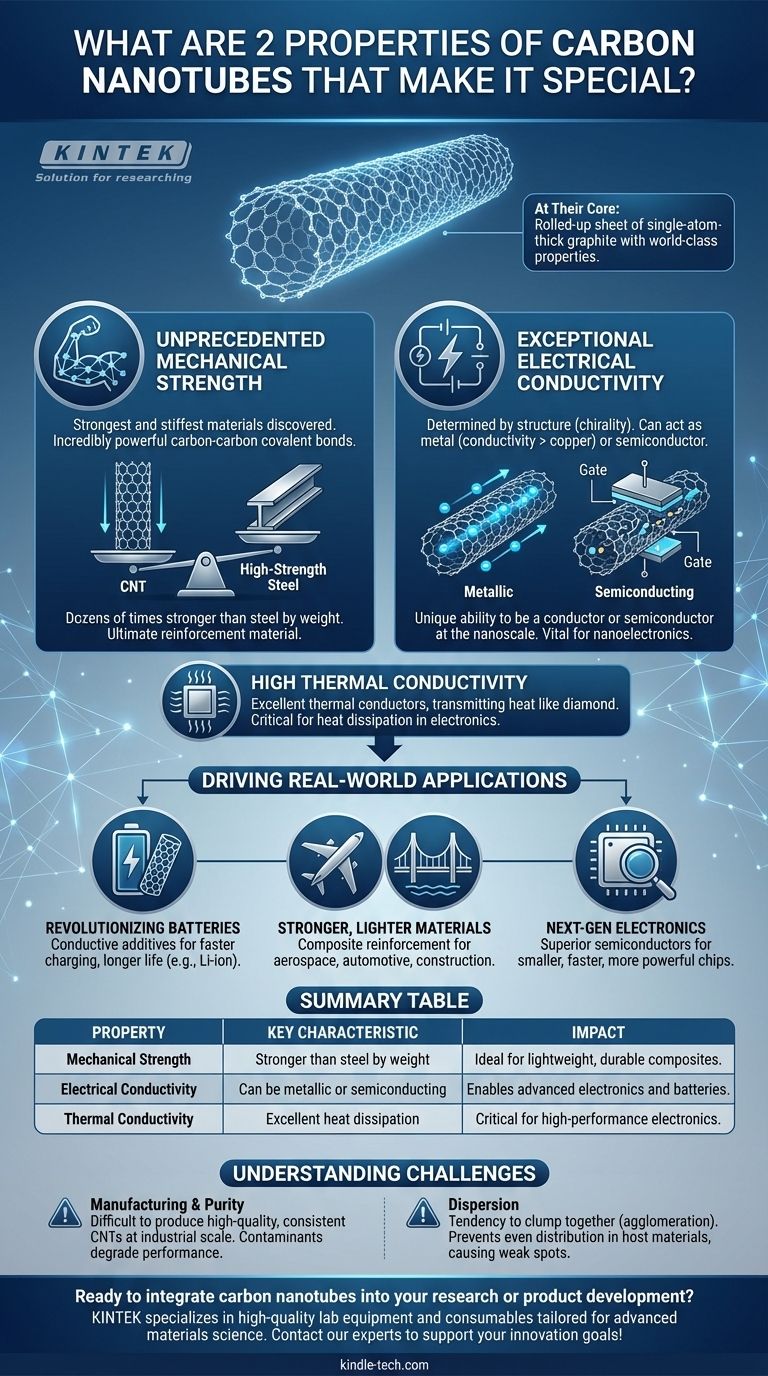

At their core, two of the most remarkable properties of carbon nanotubes (CNTs) are their exceptional mechanical strength and their unique electrical conductivity. These attributes, possessed by a material that is essentially a rolled-up sheet of single-atom-thick graphite, allow CNTs to outperform traditional materials in a vast range of applications, from reinforcing concrete to building next-generation batteries.

The true significance of carbon nanotubes is not just having one elite property, but combining world-class strength, low weight, and tunable electrical and thermal conductivity at the nanoscale. This unprecedented combination is what makes them a foundational material for future technology.

The Core Properties Explained

To understand why CNTs are so revolutionary, we must look at their specific characteristics. While they have many unique qualities, their mechanical and electrical properties are the most transformative.

Unprecedented Mechanical Strength

Carbon nanotubes are the strongest and stiffest materials yet discovered in terms of tensile strength and elastic modulus. The carbon-carbon covalent bonds that form their structure are incredibly powerful.

To put this into perspective, a CNT is dozens of times stronger than high-strength steel by weight. This phenomenal strength-to-weight ratio makes them the ultimate reinforcement material.

Exceptional Electrical Conductivity

The electrical properties of a carbon nanotube are determined by its structure—specifically, the angle at which the graphite sheet is "rolled up" (its chirality).

Depending on this structure, a CNT can act as a metal with conductivity higher than copper, or it can behave as a semiconductor, similar to silicon. This ability to be either a conductor or a semiconductor at the molecular level is unique and highly valuable for nanoelectronics.

High Thermal Conductivity

In addition to their other properties, CNTs are also excellent thermal conductors. They can transmit heat as effectively as diamond or graphite along their length.

This ability to efficiently manage and dissipate heat is critical for applications in electronics, where overheating is a primary cause of performance degradation and failure.

Understanding the Trade-offs and Challenges

Despite their groundbreaking potential, the widespread adoption of carbon nanotubes is hindered by significant practical challenges. Their performance in a lab is often difficult to replicate in mass-produced products.

The Challenge of Manufacturing and Purity

Producing high-quality CNTs with consistent properties (like length, diameter, and chirality) at an industrial scale is difficult and expensive.

Contaminants, such as amorphous carbon or residual metal catalysts from the production process, can degrade their performance and create reliability issues in sensitive applications like electronics.

The Problem of Dispersion

Carbon nanotubes have a strong tendency to clump together due to powerful intermolecular forces. This agglomeration prevents them from being evenly distributed within a host material, like a polymer or concrete mix.

If not properly dispersed, you get a composite with weak spots rather than a uniformly reinforced material, completely negating the benefits of adding CNTs in the first place.

How These Properties Drive Real-World Applications

The unique combination of properties in CNTs directly translates into tangible benefits across multiple industries.

Revolutionizing Energy Storage

In lithium-ion batteries, CNTs are used as conductive additives. Their high conductivity creates an efficient electrical network within the electrode, allowing for faster charging and discharging and improving overall battery longevity. This is one of their most successful commercial applications to date.

Creating Stronger, Lighter Materials

By integrating CNTs into polymers, metals, or concrete, engineers can create composite materials that are significantly stronger and lighter. This has profound implications for the aerospace, automotive, and construction industries, enabling more fuel-efficient vehicles and more durable infrastructure.

Powering Next-Generation Electronics

Because CNTs can act as superior semiconductors, they are a leading candidate to replace silicon in future transistors. Their small size could allow for even more densely packed and powerful computer chips, pushing beyond the physical limits of current technology.

Making the Right Choice for Your Goal

Understanding the core properties of CNTs allows you to see where they can provide the most value for a specific objective.

- If your primary focus is energy storage: Leverage their electrical conductivity to enhance the performance and lifespan of batteries and supercapacitors.

- If your primary focus is materials science: Use their mechanical strength as a lightweight reinforcement agent to create next-generation composite materials.

- If your primary focus is advanced electronics: Explore their unique semiconductor properties to design smaller, faster, and more efficient transistors and sensors.

Ultimately, mastering the use of carbon nanotubes is about harnessing their combination of elite properties while navigating the very real challenges of manufacturing and implementation.

Summary Table:

| Property | Key Characteristic | Impact |

|---|---|---|

| Mechanical Strength | Stronger than steel by weight | Ideal for lightweight, durable composites |

| Electrical Conductivity | Can be metallic or semiconducting | Enables advanced electronics and batteries |

| Thermal Conductivity | Excellent heat dissipation | Critical for high-performance electronics |

Ready to integrate carbon nanotubes into your research or product development? KINTEK specializes in providing high-quality lab equipment and consumables tailored for advanced materials science. Our expertise ensures you have the right tools to harness the unique properties of CNTs for your specific applications, from energy storage to composite materials. Contact our experts today to discuss how we can support your innovation goals!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- What are nanotubes drawbacks? The 4 Major Hurdles Limiting Their Real-World Use

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance