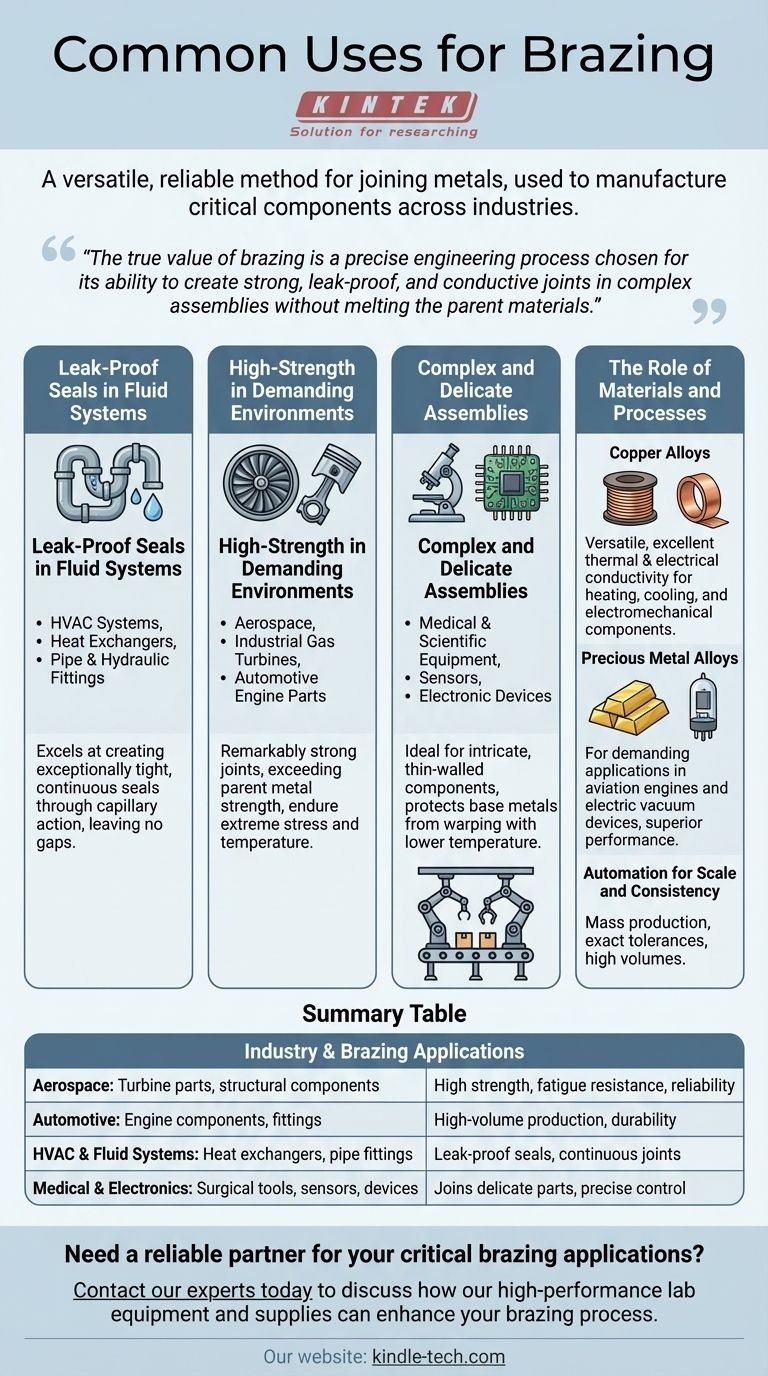

At its core, brazing is a highly versatile and reliable method for joining metals. It is commonly used to manufacture critical components across a vast range of industries, including automotive parts, HVAC systems, aerospace components, medical devices, and electronics.

The true value of brazing isn't just in joining two pieces of metal. It's a precise engineering process chosen for its ability to create strong, leak-proof, and conductive joints in complex assemblies without melting or damaging the parent materials.

Why Brazing is Chosen for Critical Components

Brazing operates at a lower temperature than welding, melting only a filler metal that flows between the closely fitted surfaces of the parts being joined. This fundamental difference is what makes it uniquely suitable for a variety of high-stakes applications.

For Leak-Proof Seals in Fluid Systems

Many brazing applications involve managing the flow of gas or liquid. Brazing excels at creating exceptionally tight, continuous seals.

This is why it's the standard for HVAC system components, heat exchangers, pipe fittings, and hydraulic fittings. The capillary action of the molten filler metal ensures it penetrates the entire joint, leaving no gaps.

For High-Strength in Demanding Environments

A properly brazed joint is remarkably strong, often exceeding the strength of the parent metals themselves. This makes it essential for parts that must endure extreme stress, vibration, and temperature.

Applications like aerospace components, industrial gas turbine parts, and automotive engine components rely on brazing to ensure structural integrity and operational reliability under harsh conditions.

For Complex and Delicate Assemblies

Because brazing doesn't melt the base metals, it is ideal for joining intricate or thin-walled components that would be warped or destroyed by higher-temperature processes like welding.

This makes it perfect for medical and scientific equipment, sensors, and electronic devices. The process allows for precise control, which is critical for maintaining the tight tolerances of these sophisticated parts.

The Role of Materials and Processes

The choice of filler metal and the brazing method are tailored to the specific demands of the application, from mass-produced automotive parts to mission-critical aerospace assemblies.

The Versatility of Copper Alloys

Copper-based filler metals are the workhorses of the brazing world. They are used to join a wide variety of materials, including carbon steel, stainless steel, and cast iron.

Their excellent thermal and electrical conductivity makes them the primary choice for heating and cooling assemblies as well as electromechanical components.

The Precision of Precious Metal Alloys

For the most demanding applications, specialized filler metals are used. Gold-based alloys, for example, are used to braze critical parts in aviation engines and electric vacuum devices.

These materials are chosen for their superior performance and reliability in environments where failure is not an option.

Automation for Scale and Consistency

In sectors like automotive manufacturing, consistency and volume are paramount. Automatic brazing machines are employed for mass production.

These systems can be programmed to produce huge volumes of parts with exact tolerances, ensuring that every brazed component meets precise engineering specifications.

Making the Right Choice for Your Goal

Understanding the unique strengths of brazing helps clarify when it is the superior joining method for a given engineering challenge.

- If your primary focus is creating leak-tight seals: Brazing is the definitive choice for hydraulic, pneumatic, and HVAC systems.

- If your primary focus is joining dissimilar or delicate materials: Brazing's lower temperature protects sensitive components, making it ideal for medical devices, sensors, and electronics.

- If your primary focus is high-strength and fatigue resistance: Brazing is trusted for mission-critical aerospace, automotive, and industrial components.

- If your primary focus is high-volume, repeatable production: Automated brazing provides a fast and reliable method for manufacturing parts with precise tolerances.

Ultimately, brazing is a sophisticated joining solution used when the performance and integrity of the final bond are absolutely critical.

Summary Table:

| Industry | Common Brazing Applications | Key Benefits |

|---|---|---|

| Aerospace | Turbine parts, structural components | High strength, fatigue resistance, reliability |

| Automotive | Engine components, fittings | High-volume production, durability |

| HVAC & Fluid Systems | Heat exchangers, pipe fittings | Leak-proof seals, continuous joints |

| Medical & Electronics | Surgical tools, sensors, devices | Joins delicate parts, precise control |

Need a reliable partner for your critical brazing applications? The right equipment and consumables are essential for creating strong, leak-proof, and precise joints. KINTEK specializes in high-performance lab equipment and supplies for thermal processing, serving industries from aerospace to medical devices. Contact our experts today to discuss how our solutions can enhance your brazing process and ensure the integrity of your most critical components.

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- Can nitrogen gas be heated? Leverage Inert Heat for Precision and Safety

- What provides an inert atmosphere? Achieve Safety and Purity with Nitrogen, Argon, or CO2

- What is meant by inert atmosphere? A Guide to Preventing Oxidation & Ensuring Safety

- What is an inert atmosphere heat treatment? Protect Your Metals from Oxidation & Decarburization

- How we can develop inert atmosphere for a chemical reaction? Master Precise Atmospheric Control for Your Lab