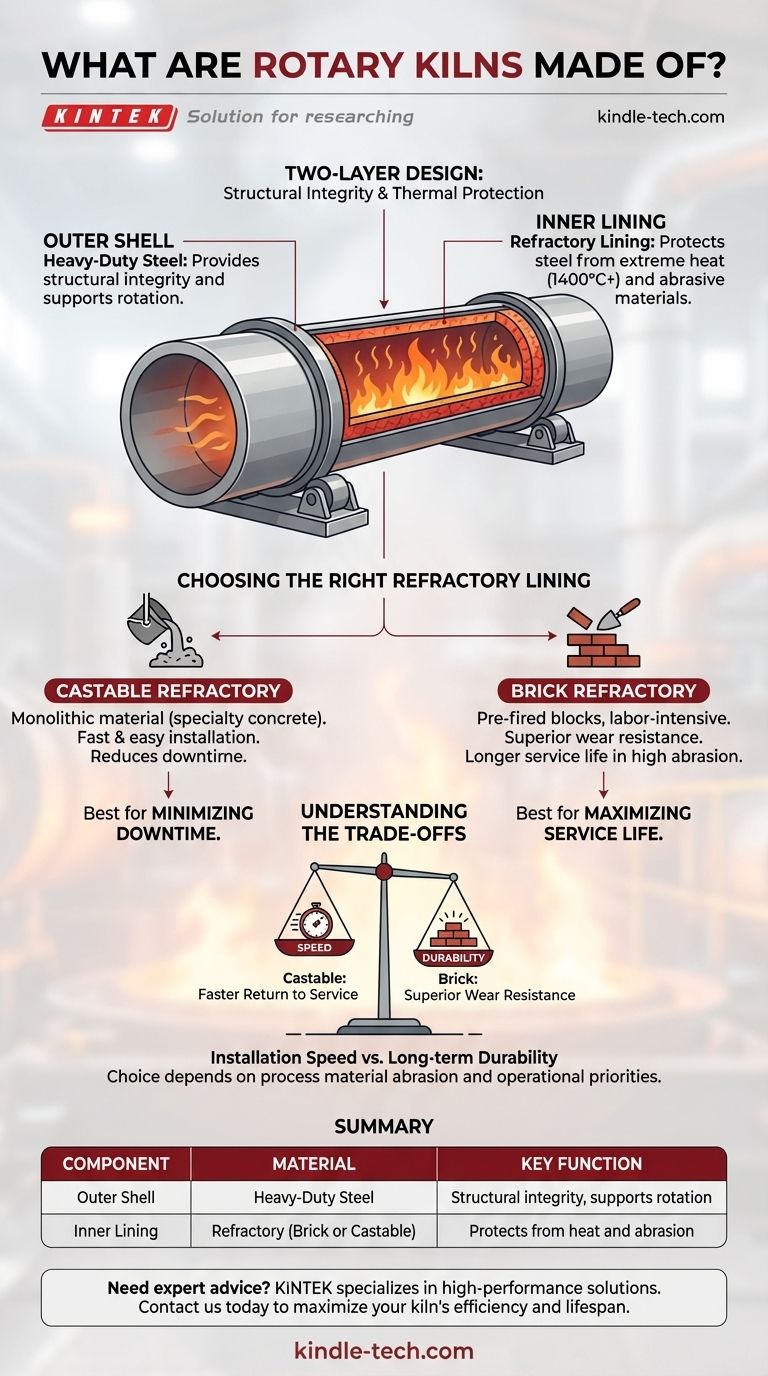

At its core, a rotary kiln is constructed from two primary materials: a strong outer steel shell and a highly durable inner refractory lining. This two-layer design is fundamental to its function, allowing the kiln to maintain structural integrity while withstanding the extreme internal conditions required for industrial thermal processing.

The selection of materials for a rotary kiln is not a single choice but a strategic balance. The outer steel cylinder provides the structure, while the internal refractory lining—either castable or brick—is chosen specifically to protect that structure from the intense heat and abrasion of the process material.

The Fundamental Two-Layer Design

A rotary kiln's construction is a direct response to its operational demands: containing and processing materials at extremely high temperatures while rotating continuously. This is achieved through a robust, two-part system.

The Outer Shell: Structural Steel

The main body of the kiln is a large, cylindrical tube made of heavy-duty steel. This shell provides the necessary structural rigidity to span across support rollers and maintain its shape during rotation.

The steel is chosen for its strength and durability, forming the backbone of the entire apparatus. It is this steel cylinder that is slightly inclined and rotated by a motor, enabling the slow movement of material from one end to the other.

The Inner Lining: Protective Refractory

The steel shell cannot be directly exposed to the process. The intense heat from fuels like pulverized coal and the abrasive nature of materials like cement clinker would quickly destroy it.

To solve this, the inside of the steel shell is coated with a refractory lining. This layer acts as a thermal and physical shield, protecting the steel from temperatures that can exceed 1400°C (2550°F) and the constant wear from tumbling solids.

Choosing the Right Refractory Lining

The choice of refractory material is one of the most critical decisions in kiln design and maintenance, as it directly impacts performance and operational lifespan. The two main options are castable and brick.

Castable Refractory

Castable refractory is a monolithic material, similar to a high-performance specialty concrete. It is mixed and then poured or gunned into place inside the kiln shell, hardening to form a solid, seamless lining.

Its primary advantage is the speed and ease of installation, which can significantly reduce downtime during maintenance or repair cycles.

Brick Refractory

Brick refractory consists of pre-fired, high-density blocks that are individually installed by skilled masons to create a tightly-fitted lining. This method is more labor-intensive and time-consuming than using castable.

However, refractory bricks generally offer superior wear resistance, making them the preferred choice for zones that experience high levels of abrasion from the process material.

Understanding the Trade-offs

While both lining types are comparably priced for similar chemical compositions, the true difference lies in their performance characteristics and the labor required to install them.

Installation Speed vs. Durability

The central trade-off is between installation speed and long-term durability. Castable linings can get a kiln back into service faster, a critical factor for minimizing production loss.

Brick linings, while taking longer to install, often provide a longer service life in highly abrasive applications, leading to fewer shutdowns for relining over the kiln's lifetime.

The Impact of Process Material

The material being processed inside the kiln is a deciding factor. For extremely abrasive materials like iron ore pellets or certain types of cement clinker, the superior mechanical strength of brick refractory is often necessary.

For less abrasive processes or in sections of the kiln with lower wear, castable refractory can be a more than adequate and cost-effective solution. The choice is about matching the lining's properties to the specific demands of the process.

Making the Right Choice for Your Application

The optimal material selection depends entirely on your operational priorities and the specific nature of your thermal process.

- If your primary focus is minimizing downtime during installation: Castable refractory is the superior choice due to its faster, monolithic application.

- If your primary focus is maximizing service life with highly abrasive materials: Brick refractory provides the best resistance to mechanical wear and will often last longer in harsh conditions.

- If your primary focus is overall structural integrity: This is non-negotiable and relies on a properly engineered steel shell designed to handle the specific rotational stresses and load of your operation.

Ultimately, understanding the interplay between the steel shell and the refractory lining is key to ensuring a rotary kiln's reliability and efficiency.

Summary Table:

| Component | Material | Key Function |

|---|---|---|

| Outer Shell | Heavy-Duty Steel | Provides structural integrity and supports rotation |

| Inner Lining | Refractory (Brick or Castable) | Protects steel from extreme heat and abrasive materials |

Need expert advice on selecting the right materials for your rotary kiln? KINTEK specializes in high-performance lab equipment and industrial thermal processing solutions. Our team can help you choose the optimal refractory lining and structural components to maximize your kiln's efficiency and lifespan. Contact us today to discuss your specific application needs!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the temperature for activated carbon regeneration? Key Ranges from 220°C to 900°C

- Can you regenerate activated charcoal? The Truth About Reusing Spent Carbon Filters

- What temperature is needed for pyrolysis of plastic? Unlock the Right Heat for Your Desired Output

- What are the distinct regions within the material bed during the rolling mode of motion? Optimize Mixing Efficiency

- How does pyrolysis start? Unlock the Molecular Trigger for Efficient Biomass Conversion

- What are the features of a rotary kiln? Achieve Uniform High-Temperature Processing

- What is a rotary kiln reactor? A Guide to Industrial Thermal Processing

- What are the catalysts for fast pyrolysis? Overcoming Biomass Conversion Challenges