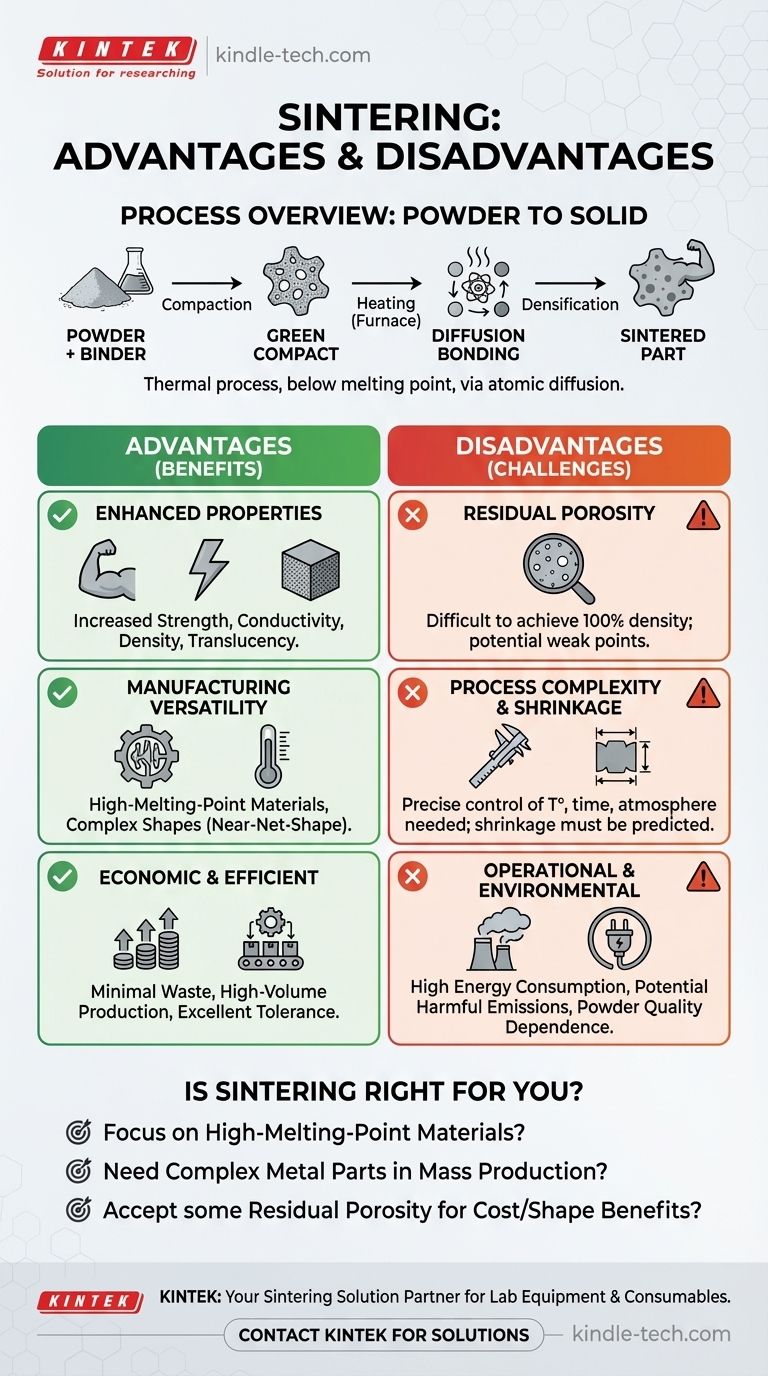

In short, sintering is a thermal process used to create dense, strong objects from a powder compact, offering significant advantages in material properties and manufacturing efficiency. Its primary benefits include the ability to process high-melting-point materials, create complex shapes with minimal waste, and enhance strength, conductivity, and density. However, these benefits are balanced by challenges such as achieving full density, the need for precise process control, and potential environmental emissions.

Sintering's core value lies in its ability to transform loose powder into a solid, high-performance part without melting it. This makes it uniquely suited for materials and geometries that are difficult or expensive to produce with other methods, but success requires a deep understanding of its inherent trade-offs.

How Sintering Fundamentally Transforms Materials

Sintering is not a melting process. Instead, it relies on atomic diffusion at temperatures below the material's melting point to fundamentally alter its structure and properties.

The Starting Point: The "Green" Compact

The process begins with a powder that is compacted into a desired shape, often using a binder. This initial, fragile object is known as a "green" compact or "green body."

The Mechanism: Diffusion Bonding

The green compact is heated in a furnace. At high temperatures, the powder particles begin to diffusion bond at their points of contact. Atoms move across the boundaries of the particles, causing the contact points to grow and pull the particle centers closer together.

The Result: Densification and Pore Removal

This atomic movement gradually eliminates the empty spaces, or pores, between the powder particles. The result is a denser, stronger, and more consolidated final part with significantly reduced porosity and improved integrity.

Key Advantages of the Sintering Process

The unique mechanism of sintering gives rise to several distinct advantages in both material science and manufacturing operations.

Enhanced Material Properties

By eliminating internal pores, sintering directly improves a material's physical characteristics. It leads to a significant increase in material strength, thermal conductivity, and electrical conductivity, as the consolidated structure provides a clearer path for energy and load transfer. In ceramics, it can even increase translucency.

Manufacturing Versatility

Sintering excels where other processes fail. Because it operates below the melting point, it is one of the few viable methods for fabricating parts from materials with extremely high melting points, such as tungsten or molybdenum. It also enables the creation of highly complex parts and intricate shapes directly from a mold, a method known as near-net-shape manufacturing.

Economic and Production Efficiency

Compared to subtractive manufacturing (like machining), sintering produces very little material waste, making it highly cost-effective. The process is also well-suited for high-volume production, offering consistent results and excellent tolerance control and surface finishes with fewer imperfections than casting.

Understanding the Trade-offs and Limitations

While powerful, sintering is not without its challenges. An objective evaluation requires acknowledging its inherent limitations.

The Challenge of Residual Porosity

Although sintering significantly reduces porosity, achieving 100% density is extremely difficult. Some residual porosity often remains, which can act as a stress concentration point and limit the ultimate mechanical performance of the component.

Process Complexity and Shrinkage

The sintering process is highly sensitive to parameters like temperature, time, and atmosphere. As the part densifies, it also shrinks. This shrinkage must be precisely predicted and controlled to achieve the desired final dimensions, which can be a complex engineering challenge.

Material and Powder Quality

The entire process is dependent on the quality of the initial powder. Factors like particle size, shape, and purity have a profound impact on the final properties of the sintered part. Inconsistent powder can lead to inconsistent results.

Environmental and Regulatory Hurdles

Sintering furnaces operate at very high temperatures. This can lead to the burnout of binders and the release of harmful emissions, which are often subject to strict environmental regulations. While the process reduces material waste (a positive), managing its energy consumption and emissions is a critical operational consideration.

Is Sintering the Right Choice for Your Application?

Choosing a manufacturing process requires aligning its capabilities with your primary goal. Sintering should be considered when its unique advantages directly solve your core engineering or business problem.

- If your primary focus is performance with high-melting-point materials: Sintering is often the most practical and sometimes the only viable manufacturing method available.

- If your primary focus is mass production of complex metal parts: Sintering offers a compelling economic advantage through near-net-shape manufacturing, drastically reducing material waste and post-processing costs compared to machining.

- If your primary focus is achieving absolute maximum density and strength: Be aware that standard sintering may leave residual porosity. You may need to consider it as a precursor to secondary densification processes like Hot Isostatic Pressing (HIP).

Ultimately, mastering sintering involves leveraging its unique ability to build strong parts from powder while diligently managing its process variables and inherent constraints.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Material Properties | Increased strength, conductivity, and density | Difficult to achieve 100% density (residual porosity) |

| Manufacturing | Processes high-melting-point materials; creates complex shapes with minimal waste | Precise control of temperature, time, and atmosphere is critical |

| Economics | Cost-effective for high-volume production; excellent tolerance control | High dependence on consistent, high-quality powder feedstock |

| Operational | Near-net-shape manufacturing reduces post-processing | High energy consumption and potential for harmful emissions |

Ready to leverage sintering for your lab's material processing needs?

At KINTEK, we specialize in providing the high-quality lab equipment and consumables essential for mastering the sintering process. Whether you are developing new materials or optimizing production, our solutions help you achieve precise temperature control, consistent results, and superior material properties.

Contact us today using the form below to discuss how our expertise can enhance your sintering applications and drive your research or production forward.

Contact KINTEK for Your Sintering Solutions

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations