Sealed quench furnaces provide superior process control and metallurgical consistency by integrating heating and quenching in a single, controlled-atmosphere chamber. Their primary advantages include producing a uniform temperature field for repeatable results, high energy efficiency, and delivering a clean, bright part finish that often eliminates the need for post-processing.

The core advantage of a sealed quench furnace is its ability to maintain a precisely controlled, oxygen-free atmosphere throughout the entire heat treatment and quenching cycle. This prevents oxidation and decarburization, ensuring predictable metallurgical outcomes and a superior surface finish.

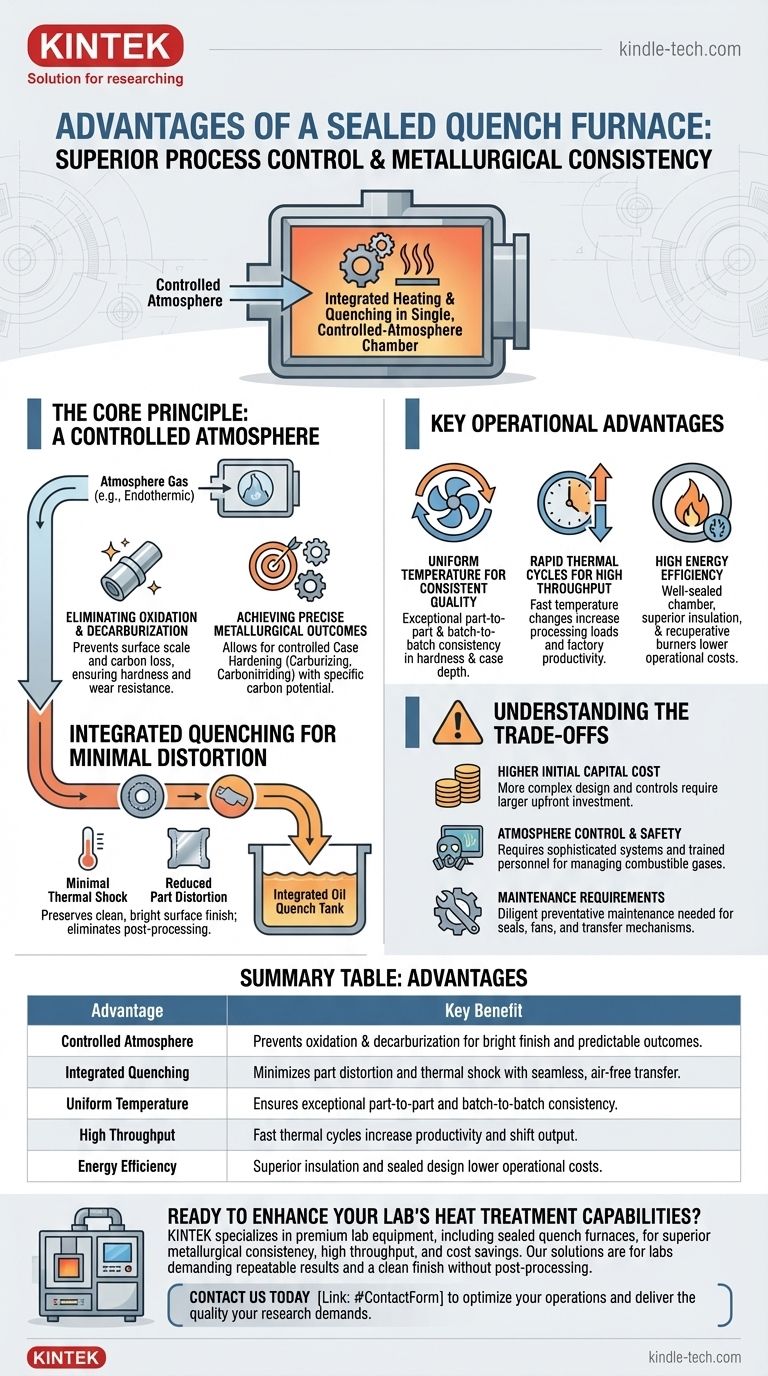

The Core Principle: A Controlled Atmosphere

The defining feature of a sealed quench furnace, also known as an Integral Quench (IQ) furnace, is its sealed chamber. This design is fundamental to all of its primary benefits.

Eliminating Oxidation and Decarburization

By sealing the heating chamber from outside air, the furnace prevents oxygen from reacting with the hot steel parts. This process, called oxidation, creates scale on the part surface that must be cleaned off later.

The controlled atmosphere also prevents decarburization, which is the loss of carbon from the surface of the steel. This ensures the material's surface hardness and wear resistance are not compromised.

Achieving Precise Metallurgical Outcomes

The furnace atmosphere isn't just a vacuum; it's a carefully managed environment. Gases like endothermic gas are introduced to achieve a specific carbon potential.

This allows for precise control over case hardening processes like carburizing and carbonitriding, where carbon is intentionally added to the steel's surface to a specified depth and concentration.

Integrated Quenching for Minimal Distortion

The "quench" in the name refers to the integrated, sealed quenching tank, typically filled with oil. Parts are transferred from the hot zone to the quench vestibule without ever being exposed to ambient air.

This seamless transfer minimizes thermal shock and part distortion, while also preserving the clean, bright surface finish achieved in the heating chamber.

Key Operational Advantages

The design of a sealed quench furnace leads directly to significant improvements in efficiency, consistency, and throughput.

Uniform Temperature for Consistent Quality

These furnaces are engineered with powerful circulation fans and advanced heating systems (gas-fired or electric) to create a highly uniform temperature field.

This ensures that every part in the load, whether at the top, bottom, or center, receives the exact same thermal cycle. The result is exceptional part-to-part and batch-to-batch consistency in hardness and case depth.

Rapid Thermal Cycles for High Throughput

Modern sealed quench furnaces use lightweight ceramic fiber insulation and efficient heating systems. This allows them to achieve fast temperature rise and fall times.

Faster cycles mean more loads can be processed per shift, directly increasing factory throughput and productivity.

High Energy Efficiency

The combination of a well-sealed chamber, superior insulation, and often recuperative burner systems (which use exhaust heat to preheat combustion air) makes these furnaces highly energy efficient.

This significantly reduces heat loss to the surrounding environment, lowering operational fuel or electricity costs compared to older, less contained designs.

Understanding the Trade-offs

While highly effective, sealed quench furnaces are not the solution for every application. Understanding their limitations is key to making an informed decision.

Higher Initial Capital Cost

The complexity of the sealed design, atmosphere controls, and integrated mechanics results in a higher upfront investment compared to simpler equipment like open-fire or pit furnaces.

Atmosphere Control and Safety

Managing a combustible atmosphere gas requires sophisticated control systems, including oxygen probes and flow meters, as well as strict safety protocols. This adds a layer of operational complexity and requires trained personnel.

Maintenance Requirements

The seals, internal fans, radiant tubes, and transfer mechanisms are critical components that require a diligent preventative maintenance program to ensure reliability and safety.

Making the Right Choice for Your Goal

Selecting the right furnace technology depends entirely on your production requirements and quality standards.

- If your primary focus is high-volume, repeatable case hardening: The sealed quench furnace is the industry standard due to its unmatched process control and efficiency.

- If your primary focus is minimizing post-treatment processing: The bright, clean finish produced by this furnace eliminates the need for shot blasting, saving significant labor and operational costs.

- If your primary focus is process flexibility: These furnaces can be easily programmed for carburizing, carbonitriding, neutral hardening, and annealing by simply adjusting the cycle and atmosphere.

Ultimately, investing in a sealed quench furnace is an investment in process repeatability, final part quality, and overall operational efficiency.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Controlled Atmosphere | Prevents oxidation & decarburization for a bright finish and predictable outcomes. |

| Integrated Quenching | Minimizes part distortion and thermal shock with seamless, air-free transfer. |

| Uniform Temperature | Ensures exceptional part-to-part and batch-to-batch consistency. |

| High Throughput | Fast thermal cycles increase productivity and shift output. |

| Energy Efficiency | Superior insulation and sealed design lower operational costs. |

Ready to enhance your lab's heat treatment capabilities?

KINTEK specializes in premium lab equipment, including sealed quench furnaces, to help you achieve superior metallurgical consistency, high throughput, and significant cost savings. Our solutions are designed for laboratories that demand repeatable results and a clean finish without post-processing.

Contact us today to discuss how a sealed quench furnace can optimize your operations and deliver the quality your research demands.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vertical Laboratory Tube Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What is the structure of a vacuum furnace? A Guide to Its Core Components & Functions

- What are the advantages of a vacuum furnace? Achieve Superior Purity and Control in Heat Treatment

- What is a vacuum furnace? The Ultimate Guide to Contamination-Free Thermal Processing