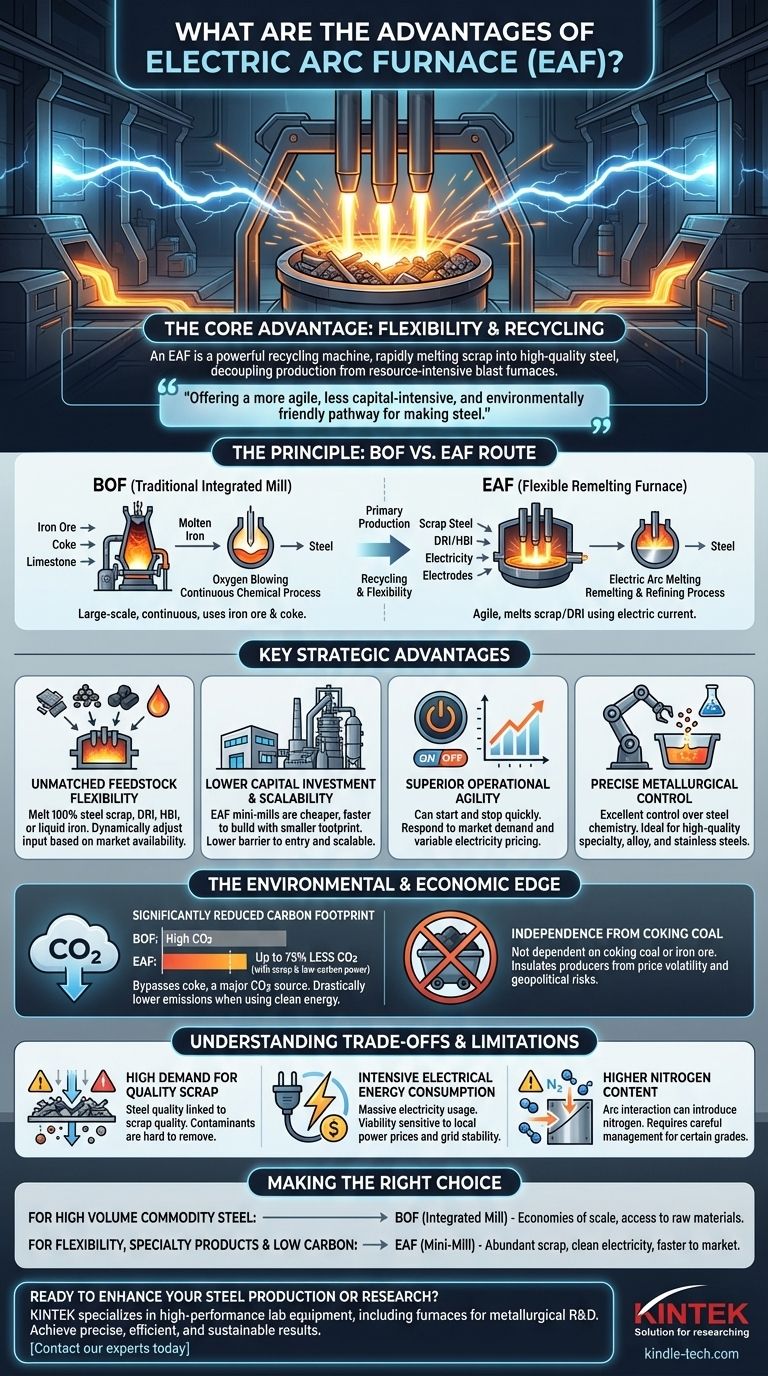

At its core, the primary advantage of the electric arc furnace (EAF) is its remarkable flexibility. Unlike traditional steelmaking methods that rely on a lengthy, integrated process starting from iron ore, an EAF is essentially a highly efficient and powerful recycling machine that can rapidly melt scrap steel or other iron sources into new, high-quality steel.

The electric arc furnace decouples steel production from the resource-intensive blast furnace process, offering a more agile, less capital-intensive, and often more environmentally friendly pathway for making steel, particularly when using recycled scrap.

The Principle: A High-Powered Melting Pot

To understand the advantages of an EAF, it's crucial to distinguish it from its primary alternative, the Basic Oxygen Furnace (BOF).

The Traditional BOF Route

A BOF is part of an integrated steel mill. It takes molten iron, produced in a massive blast furnace from iron ore and coke, and refines it into steel by blowing oxygen through it. This is a large-scale, continuous chemical process.

The Flexible EAF Route

An EAF is a remelting furnace. It uses enormous graphite electrodes to pass an electric current through a metal charge, creating an arc with temperatures hot enough to melt the metal. It doesn't refine iron ore; it primarily melts pre-existing steel (scrap) or direct reduced iron (DRI).

Key Strategic Advantages of EAF Technology

The EAF's operational model gives rise to several distinct benefits in finance, operations, and environmental impact.

Unmatched Feedstock Flexibility

The EAF is not locked into a single raw material. It can melt a wide variety of ferrous materials, including 100% steel scrap, DRI, hot briquetted iron (HBI), or even liquid iron. This allows producers to dynamically adjust their input based on market price and availability.

Lower Capital Investment and Scalability

Building an integrated mill with a blast furnace and BOF is a multi-billion dollar, decade-long undertaking. An EAF-based "mini-mill" is significantly cheaper and faster to build, requiring a much smaller footprint and less infrastructure. This lowers the barrier to entry and allows for more scalable, modular growth.

Superior Operational Agility

An EAF can be started and stopped relatively quickly. This "on-off" capability is impossible for a blast furnace, which must run continuously for years. This agility allows EAF operators to respond to market demand fluctuations and even take advantage of variable electricity pricing.

Precise Metallurgical Control

The EAF process allows for excellent control over the final steel chemistry. Alloying elements can be added with high precision during the melt, making it exceptionally well-suited for producing high-quality specialty steels, alloy steels, and stainless steels.

The Environmental and Economic Edge

In an increasingly carbon-conscious world, the EAF's environmental profile is one of its most compelling advantages.

Significantly Reduced Carbon Footprint

When using 100% scrap steel and powered by a low-carbon electricity grid, an EAF can produce steel with up to 75% fewer carbon emissions compared to the traditional blast furnace route. It completely bypasses the need for coke, a major source of CO2 in integrated steelmaking.

Independence from Coking Coal

The EAF process is not dependent on coking coal or iron ore, insulating producers from the price volatility and geopolitical supply risks associated with these raw materials. The primary inputs are scrap steel and electricity.

Understanding the Trade-offs and Limitations

No technology is without its challenges, and choosing an EAF requires understanding its specific dependencies.

High Demand for Quality Scrap

The quality of the finished steel is directly linked to the quality of the scrap metal used. Contaminants in the scrap, such as copper or tin, can be difficult to remove and can negatively impact the final product. Securing a consistent supply of high-quality, low-residual scrap is a major operational challenge.

Intensive Electrical Energy Consumption

As the name implies, an EAF consumes a massive amount of electricity. Its economic viability is therefore highly sensitive to local electricity prices and grid stability. Operating in a region with expensive or unreliable power can cripple an EAF's cost-competitiveness.

Higher Nitrogen Content

The electric arc's interaction with the atmosphere can introduce higher levels of nitrogen into the steel compared to the BOF process. While this can be managed with modern techniques, it requires careful control for certain steel grades where low nitrogen is critical.

Making the Right Choice for Your Goal

The decision between an EAF and a BOF depends entirely on the strategic objectives of the steel producer.

- If your primary focus is producing commodity-grade flat steel in very high volumes: The traditional integrated blast furnace and BOF route may offer superior economies of scale, provided you have access to iron ore and coking coal.

- If your primary focus is flexibility, specialty products, and a lower carbon footprint: The EAF is the clear choice, especially in regions with abundant scrap and access to affordable, clean electricity.

- If your primary focus is minimizing initial capital investment and building with speed: An EAF-based mini-mill provides a much faster and less capital-intensive path to market.

The electric arc furnace represents a modern, adaptable, and more sustainable approach to steel production.

Summary Table:

| Advantage | Description |

|---|---|

| Feedstock Flexibility | Can melt 100% scrap steel, DRI, or HBI, adapting to market prices. |

| Lower Capital Cost | EAF-based mini-mills are cheaper and faster to build than integrated mills. |

| Operational Agility | Can be started/stopped quickly to respond to demand and electricity pricing. |

| Metallurgical Control | Excellent for producing high-quality specialty, alloy, and stainless steels. |

| Reduced Carbon Footprint | Up to 75% lower emissions when using scrap and clean electricity. |

| Independence from Coal | Eliminates reliance on coking coal, mitigating price/supply risks. |

Ready to enhance your steel production or research capabilities? KINTEK specializes in supplying high-performance lab equipment, including furnaces for metallurgical research and development. Whether you're exploring new alloys or optimizing melting processes, our expertise can help you achieve precise, efficient, and sustainable results. Contact our experts today to discuss how our solutions can power your innovation.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the benefits of a heat treatment furnace? Achieve Precise Control Over Material Properties

- What is the principle of vacuum furnace? Achieve Purity and Precision in Material Processing

- What is the pressure less sintering method? Achieve Complex Shapes Without High-Pressure Equipment

- Why is it necessary to use a high-vacuum furnace during Active Metal Brazing (AMB)? Ensure Perfect Ceramic-to-Metal Bonds

- What is the role of a vacuum drying oven in pre-treating granite? Ensure Data Integrity with Low-Temp Precision

- What is the role of a high-temperature vacuum furnace in aluminide coating? Optimize Superalloy Substrate Performance

- What is the function of a Drop Tube Reactor in flash-reduced iron powder study? Precision Simulation for Rapid Reduction

- How does vacuum brazing work? Achieve Superior, Flux-Free Metal Joining