At its core, Chemical Vapor Deposition (CVD) is a uniquely versatile and powerful technique for creating high-performance thin films. Its primary advantages include the ability to produce exceptionally pure and uniform coatings over complex, non-flat surfaces with excellent adhesion. This is achieved by using gaseous chemical precursors that react on a substrate surface, fundamentally distinguishing it from line-of-sight physical deposition methods.

The crucial advantage of CVD isn't just one feature, but how its process—building a film atom-by-atom from a chemical reaction—inherently produces coatings with superior purity, density, and uniformity, even on the most intricate geometries.

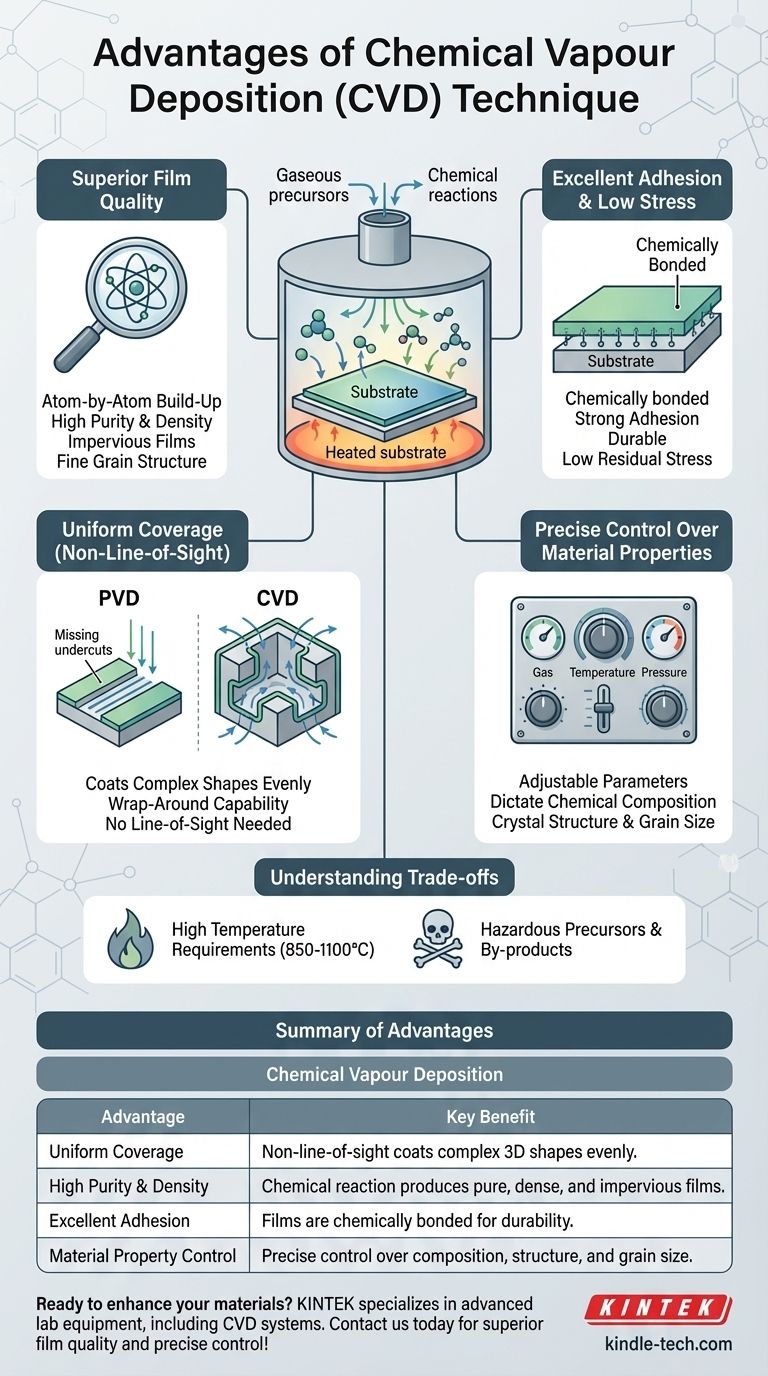

How CVD Achieves Superior Film Quality

The advantages of CVD are a direct result of its fundamental mechanism. Unlike processes that physically transfer material, CVD builds the film through a controlled chemical reaction on the target surface.

The Principle of Gaseous Precursors

The CVD process involves introducing reactive gases (precursors) into a chamber containing the object to be coated (the substrate).

When these gases reach the heated substrate, they undergo a chemical reaction or decomposition. This reaction forms the desired solid material directly onto the substrate surface, building the film layer by layer.

Achieving High Purity and Density

Because the film is formed from a chemical reaction, the process can be tuned to be highly selective. This allows for the deposition of exceptionally pure materials, as unreacted precursors and by-products are simply removed as gases.

This chemical bonding process also tends to create films that are highly dense and impervious, with fine grain structures and strong adhesion to the substrate.

Exceptional Control Over Material Properties

CVD offers a high degree of control over the final film's characteristics.

By precisely adjusting the deposition parameters—such as gas composition, flow rate, temperature, and pressure—engineers can dictate the film's chemical composition, crystal structure, and even grain size.

The Strategic Advantage of Uniform Coverage

One of the most significant operational advantages of CVD is its ability to coat complex shapes evenly, a major limitation for many other techniques.

A True Non-Line-of-Sight Process

Physical deposition methods (like sputtering) often travel in a straight line from the source to the substrate. This makes it difficult to coat undercuts, crevices, or the inside of a tube.

CVD is a non-line-of-sight process. The precursor gases flow and diffuse throughout the chamber, reaching and reacting with every exposed surface, ensuring a uniform, conformal coating regardless of geometry.

Commendable Adhesion and Low Stress

The film is not just sitting on the substrate; it is chemically bonded to it. This typically results in excellent adhesion.

Furthermore, because the film is "grown" in place under controlled thermal conditions, it can be engineered to have low residual stress, which is critical for the durability and performance of the coating.

Understanding the Trade-offs

No technique is perfect. To use CVD effectively, you must understand its limitations.

High Temperature Requirements

Traditional CVD processes often require very high substrate temperatures, typically between 850°C and 1100°C.

This heat can damage or destroy many substrate materials, such as plastics, certain metals, or complex electronic components. Modern variations like plasma-enhanced CVD (PECVD) exist to lower this temperature requirement.

Hazardous Precursors and By-products

The process relies on volatile chemical precursors, which can be toxic, flammable, or corrosive.

Additionally, the chemical reactions can produce hazardous by-product gases that must be handled and disposed of with extreme care, adding to operational complexity and cost.

Making the Right Choice for Your Goal

Selecting a deposition technique depends entirely on the specific outcome you need to achieve.

- If your primary focus is coating a complex 3D part uniformly: CVD is an ideal choice due to its non-line-of-sight nature and excellent wrap-around capability.

- If your primary focus is producing the highest purity crystalline films: CVD offers unparalleled control over purity and crystal structure, making it a standard in semiconductor and advanced materials manufacturing.

- If your primary focus is coating a temperature-sensitive material: Traditional CVD is likely unsuitable, and you should investigate lower-temperature alternatives like plasma-enhanced CVD or physical vapor deposition (PVD).

Ultimately, CVD's ability to chemically construct high-quality films makes it an indispensable tool for creating advanced materials.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Uniform Coverage | Non-line-of-sight process coats complex 3D shapes evenly. |

| High Purity & Density | Chemical reaction produces pure, dense, and impervious films. |

| Excellent Adhesion | Films are chemically bonded to the substrate for durability. |

| Material Property Control | Precise control over composition, structure, and grain size. |

Ready to enhance your materials with high-performance thin films?

KINTEK specializes in providing advanced lab equipment and consumables, including Chemical Vapor Deposition systems, to meet your specific laboratory needs. Our expertise can help you achieve superior film quality, uniform coatings on complex geometries, and precise control over material properties.

Contact us today to discuss how our CVD solutions can drive your research and development forward!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings