The primary advantage of co-pyrolysis is the positive synergistic effect that occurs when processing multiple, different feedstocks together. This interaction improves the quality and yield of valuable products like bio-oil and syngas, while also overcoming the limitations of pyrolyzing a single type of material. It takes the inherent benefits of pyrolysis—converting waste into energy—and strategically enhances them.

While standard pyrolysis is a powerful tool for converting waste into value, its output can be inconsistent or low-grade. Co-pyrolysis solves this by intentionally blending different materials to create a synergistic reaction, resulting in superior products and a more efficient, economically viable process.

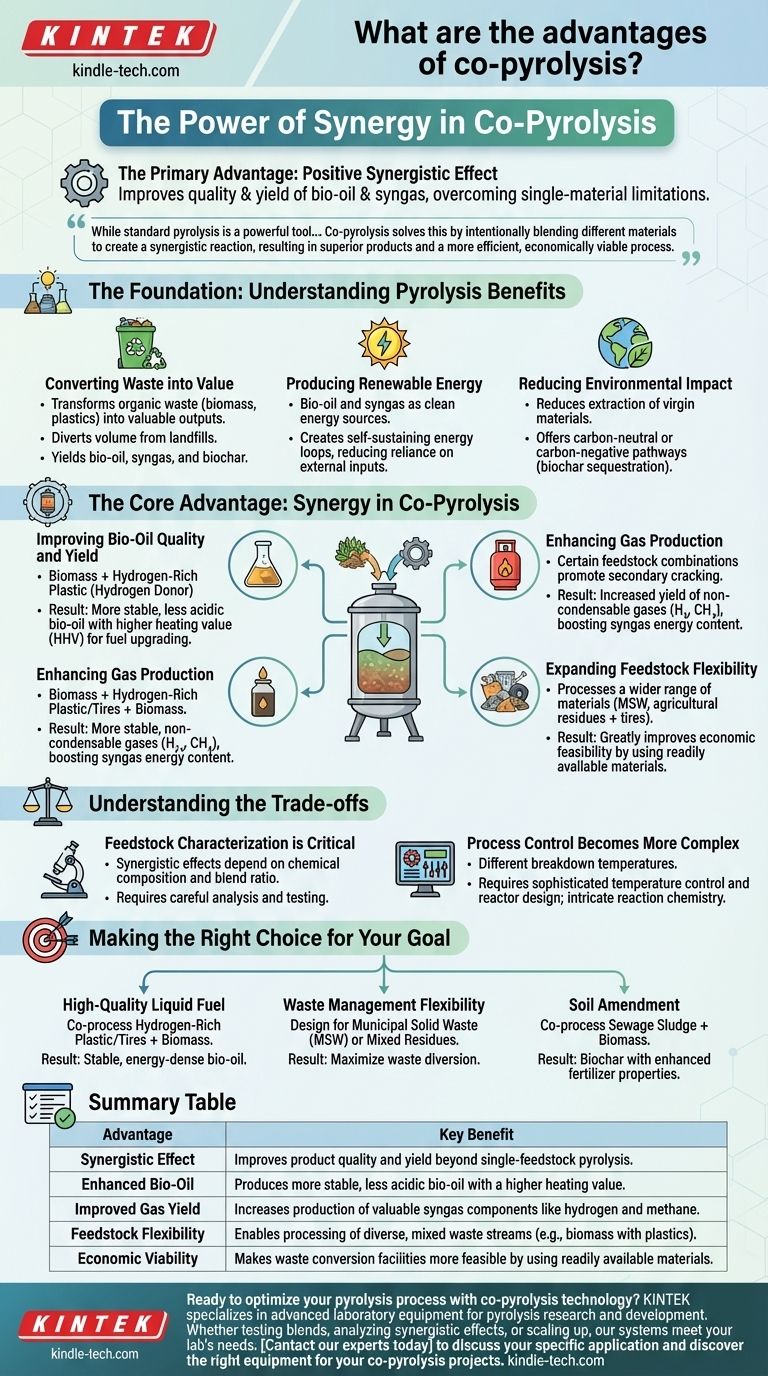

The Foundation: Understanding Pyrolysis Benefits

Before detailing the specific advantages of co-pyrolysis, it's essential to understand the value of pyrolysis itself. This thermal decomposition process forms the basis for the enhanced co-pyrolysis technique.

Converting Waste into Value

Pyrolysis transforms organic waste materials, such as agricultural residue, wood waste, and plastics, into valuable outputs. This diverts significant volume from landfills.

The process yields high-energy-density liquid fuels (bio-oil), combustible gases (syngas), and a solid carbon-rich material (biochar).

Producing Renewable Energy

The bio-oil and syngas produced can be used as clean energy sources, providing a renewable alternative to fossil fuels.

This creates a self-sustaining energy loop where the process can often power itself, reducing reliance on external energy inputs.

Reducing Environmental Impact

By utilizing waste streams, pyrolysis reduces the need to extract virgin raw materials.

It offers a carbon-neutral pathway for energy production and can even be carbon-negative through the sequestration of carbon in stable biochar, which helps reduce greenhouse gas emissions.

The Core Advantage: Synergy in Co-Pyrolysis

Co-pyrolysis is not just about processing two things at once; it's about how one feedstock improves the decomposition of the other. The most common and effective application is the co-pyrolysis of biomass with other materials like plastics or sludge.

Improving Bio-Oil Quality and Yield

Biomass on its own produces bio-oil that is often acidic, unstable, and has a high oxygen content, which lowers its energy value.

Plastics, on the other hand, are rich in hydrogen. When co-pyrolyzed with biomass, the hydrogen from the plastic can act as a hydrogen donor, leading to deoxygenation reactions.

This synergy results in a more stable, less acidic bio-oil with a higher heating value (HHV), making it a much better candidate for upgrading into transportation fuel.

Enhancing Gas Production

Certain feedstock combinations can promote secondary cracking reactions during co-pyrolysis.

This can increase the yield of valuable non-condensable gases in the syngas fraction, such as hydrogen and methane, boosting its overall energy content.

Expanding Feedstock Flexibility

Many facilities are limited by the availability of a single, consistent type of waste.

Co-pyrolysis allows for the processing of a much wider, more realistic range of available materials, such as mixed municipal solid waste or agricultural residues combined with waste tires. This greatly improves the economic feasibility of a facility.

Understanding the Trade-offs

While powerful, co-pyrolysis introduces complexities that are not present when processing a single, uniform feedstock.

Feedstock Characterization is Critical

The synergistic effects are highly dependent on the chemical composition of the feedstocks and their blend ratio.

Achieving optimal results requires careful analysis and testing to find the right recipe. An improper mix can yield poor results or even introduce unwanted contaminants.

Process Control Becomes More Complex

Different materials break down at different temperatures and rates. Managing a blended feedstock requires more sophisticated temperature control and reactor design.

The reaction chemistry is more intricate, making it harder to predict the exact composition of the final products without empirical data.

Making the Right Choice for Your Goal

The ideal co-pyrolysis strategy depends entirely on your desired outcome.

- If your primary focus is high-quality liquid fuel: Co-process a hydrogen-rich material like waste plastic or tires with biomass to produce a more stable, energy-dense bio-oil.

- If your primary focus is waste management flexibility: Design the process to handle variable inputs like municipal solid waste (MSW) or mixed agricultural residues to maximize waste diversion.

- If your primary focus is soil amendment: Co-process biomass with nutrient-rich materials like sewage sludge to create a biochar that has enhanced fertilizer properties.

Ultimately, co-pyrolysis elevates a proven technology by turning feedstock variability from a challenge into a strategic advantage.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Synergistic Effect | Improves product quality and yield beyond single-feedstock pyrolysis. |

| Enhanced Bio-Oil | Produces more stable, less acidic bio-oil with a higher heating value. |

| Improved Gas Yield | Increases production of valuable syngas components like hydrogen and methane. |

| Feedstock Flexibility | Enables processing of diverse, mixed waste streams (e.g., biomass with plastics). |

| Economic Viability | Makes waste conversion facilities more feasible by using readily available materials. |

Ready to optimize your pyrolysis process with co-pyrolysis technology?

KINTEK specializes in advanced laboratory equipment for pyrolysis research and development. Whether you are testing feedstock blends, analyzing synergistic effects, or scaling up your process, our precise and reliable systems are designed to meet your lab's needs.

Let us help you achieve superior results in waste-to-energy conversion. Contact our experts today to discuss your specific application and discover the right equipment for your co-pyrolysis projects.

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity

- How do tube furnaces or muffle furnaces ensure stoichiometric accuracy during synthesis? Mastering Li4GeO4 & Li4VO4

- What is the temperature of a rotary hearth furnace? Find the Right Heat for Your Process

- What is the function of a high-temperature furnace during burnout? Master Aluminum Foam Production with Precision

- Why is a high-temperature furnace with multi-probe testing used for ABO3 perovskite? Get Precise Conductivity Data