In essence, electron beam hardening offers significant advantages in speed, precision, and control over traditional methods. It uses a highly focused beam of electrons to rapidly heat a specific surface area, which then quickly cools (or "self-quenches") by transferring heat to the cold bulk material beneath it. This process creates a very hard surface layer with minimal distortion to the overall part.

While conventional hardening often involves heating an entire component, leading to potential warping and costly rework, electron beam hardening acts like a surgical tool. It delivers precise energy exactly where needed, preserving the part's core properties and dimensional integrity.

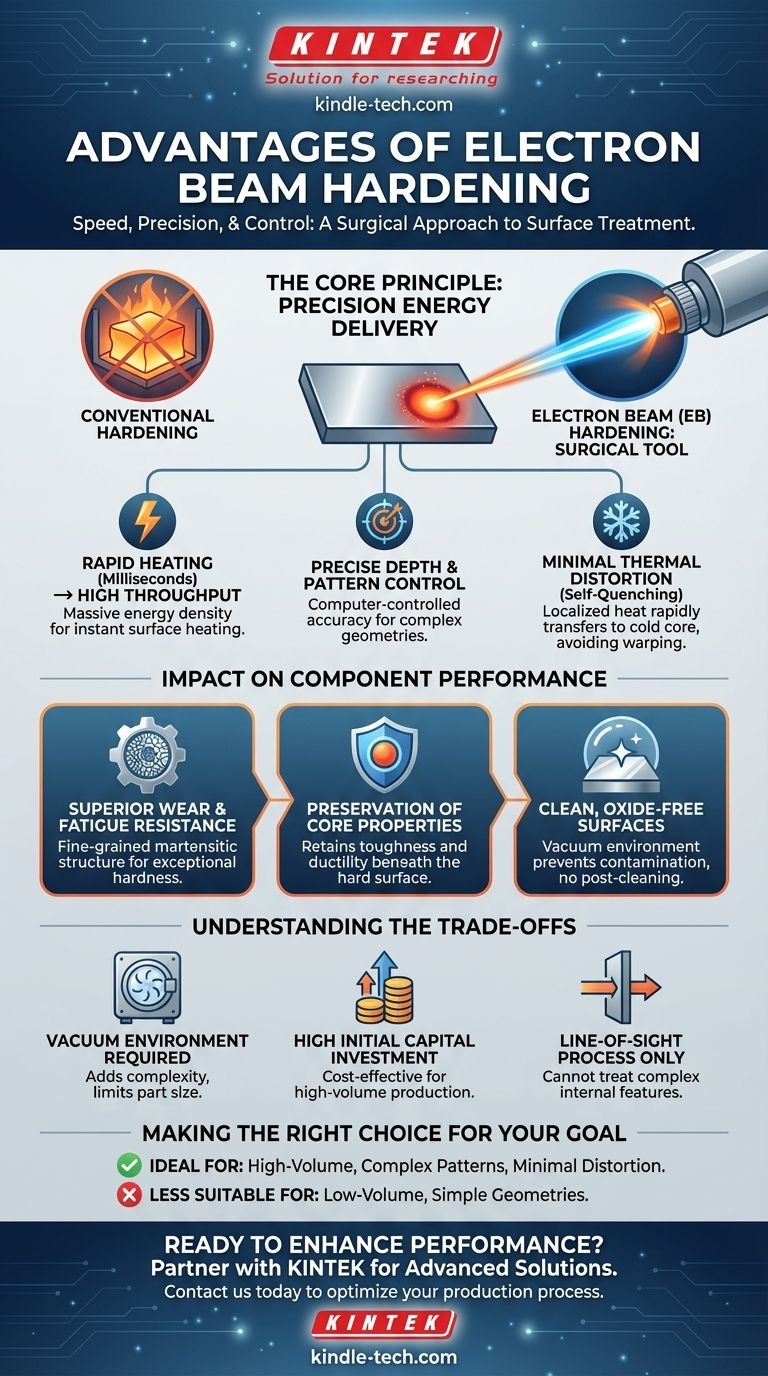

The Core Principle: Precision Energy Delivery

The strategic advantage of electron beam (EB) hardening comes from its ability to treat the material's surface without affecting the bulk of the component. This is achieved through the unique physics of the process.

High Energy Density and Speed

An electron beam concentrates a massive amount of energy into a tiny spot. This allows the surface temperature to rise to the required level for hardening in milliseconds.

This rapid heating cycle makes EB hardening one of the fastest surface treatment processes available, enabling high throughput for mass production environments.

Precise Depth and Area Control

The depth of hardening is a direct function of the beam's power and the travel speed, both of which are under precise computer control. This allows for hardening depths to be controlled with extreme accuracy.

Furthermore, the beam can be steered to follow complex patterns, ensuring that only the specific functional surfaces requiring high hardness and wear resistance are treated.

Minimal Thermal Distortion

Because the heating is so fast and localized, the vast majority of the component remains cool. The heat from the surface is rapidly conducted away into this cold mass, causing a "self-quenching" effect.

This process avoids the large-scale heating and cooling cycles of furnace or induction hardening, which are the primary causes of part distortion, warping, and changes in dimension.

The Impact on Component Performance

These process advantages directly translate into a higher-quality and more reliable finished product.

Superior Wear and Fatigue Resistance

The extremely rapid quench rates possible with EB hardening can produce a very fine-grained martensitic microstructure. This fine structure results in exceptional hardness and superior resistance to abrasion and contact fatigue.

Preservation of Core Properties

Since only the surface is altered, the core of the component retains its original properties, such as toughness and ductility. This creates a part with an ideal combination of a hard, wear-resistant surface and a tough, fracture-resistant core.

Clean, Oxide-Free Surfaces

Electron beam hardening is typically performed in a vacuum. This environment prevents oxidation and other surface contamination during the heating process, resulting in a clean finish that often requires no subsequent cleaning steps.

Understanding the Trade-offs and Limitations

No process is perfect. To make an informed decision, you must understand the specific constraints of electron beam hardening.

Requirement for a Vacuum Environment

The process must be conducted in a vacuum chamber to prevent the electron beam from scattering off air molecules. This adds to the equipment's complexity and can limit the size of the parts that can be processed.

High Initial Capital Investment

Electron beam systems are sophisticated and represent a significant capital expenditure compared to more conventional heat-treating equipment. The process is most cost-effective in high-volume production where the cost can be amortized over many parts.

Line-of-Sight Process

The electron beam travels in a straight line. Therefore, it can only harden surfaces that are in its direct line of sight, making it unsuitable for treating complex internal features or hidden surfaces.

Making the Right Choice for Your Goal

Selecting the right hardening process depends entirely on your project's specific priorities, from part geometry to production volume.

- If your primary focus is high-volume production and minimal distortion: Electron beam hardening is an exceptional choice due to its speed, repeatability, and low thermal impact.

- If your primary focus is hardening specific, complex patterns on distortion-prone parts: The precision and control of an EB system are likely superior to any bulk heating alternative.

- If your primary focus is low-volume production or treating simple geometries: The high capital cost of EB may be prohibitive, and traditional methods like induction or flame hardening might be more economical.

Ultimately, choosing electron beam hardening is a strategic decision to prioritize precision and metallurgical quality over initial equipment cost.

Summary Table:

| Advantage | Description |

|---|---|

| Speed & Throughput | Millisecond heating cycles enable high-volume production. |

| Precision Control | Computer-controlled depth and pattern hardening for complex geometries. |

| Minimal Distortion | Localized heating and self-quenching preserve part dimensions. |

| Superior Hardness | Fine-grained martensitic microstructure for exceptional wear resistance. |

| Clean Process | Vacuum environment prevents oxidation, eliminating post-cleaning. |

Ready to enhance your component performance with precision hardening?

At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your laboratory's needs. Our expertise in electron beam technology can help you achieve superior surface hardening with minimal distortion and maximum efficiency.

Contact us today to discuss how our solutions can optimize your production process and deliver the metallurgical quality your projects demand.

Visual Guide

Related Products

- Anti-Cracking Press Mold for Lab Use

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What products use compression molding? Manufacture Large, Durable Components

- What is the manufacturing process of rubber molding? Injection, Compression, or Transfer Molding?

- How do you prepare a maintenance list for Mould maintenance? Implement a Proactive Tiered System

- What are the advantages and disadvantages of injection molding machine? Maximize Efficiency for Mass Production

- What is the compression method of processing plastic? A Guide to Strong, Cost-Effective Molding