The primary advantages of Low Pressure Chemical Vapor Deposition (LPCVD) are its ability to produce films with exceptional purity, outstanding thickness uniformity, and excellent conformality over complex surface topographies. By operating in a vacuum, LPCVD minimizes gas-phase reactions, allowing precursor gases to deposit a superior quality film on a large number of substrates simultaneously.

LPCVD is not chosen for speed, but for quality and efficiency at scale. It leverages a low-pressure environment to achieve unparalleled film uniformity and purity across large batches of substrates, making it a cornerstone of high-precision manufacturing.

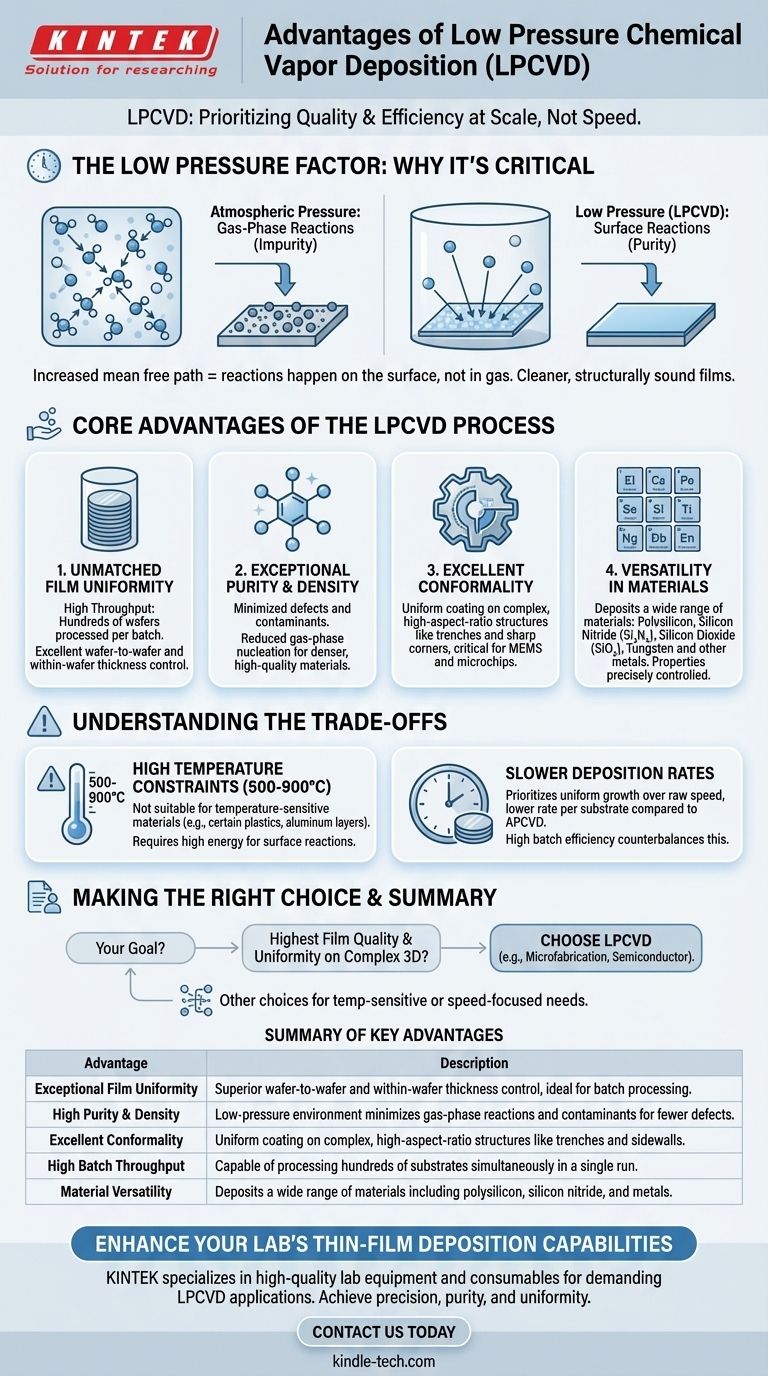

Why "Low Pressure" is the Critical Factor

To understand the benefits of LPCVD, we must first understand the impact of pressure on the deposition process. The core advantages stem directly from the vacuum conditions under which it operates.

Dominance of Surface Reactions

At low pressures, gas molecules travel further before colliding with each other. This increased mean free path means that the chemical reactions happen predominantly on the hot substrate surface, not in the gas phase above it.

This is critical because gas-phase reactions can form particles that fall onto the surface, creating defects and impurities in the film. LPCVD largely avoids this, resulting in a much purer and more structurally sound material.

Conformal Coating on Complex Shapes

The long mean free path also allows precursor gases to diffuse deep into complex, high-aspect-ratio trenches and structures before reacting. This is why LPCVD provides excellent conformality, meaning the film's thickness is uniform across flat surfaces, vertical sidewalls, and sharp corners.

Processes at higher pressure struggle with this, as reactants are often depleted before they can penetrate these complex features, leading to uneven coatings. This makes LPCVD essential for fabricating intricate devices like microchips and MEMS.

Core Advantages of the LPCVD Process

The low-pressure environment directly enables several key operational benefits that make it a preferred method for high-value applications.

Unmatched Film Uniformity

Because the process is limited by the surface reaction rate rather than mass transport of gases, the deposition is much less sensitive to patterns on the substrate or gas flow dynamics.

This allows for the vertical stacking of wafers in a tube furnace, enabling a very high throughput per batch. Hundreds of wafers can be coated in a single run with excellent wafer-to-wafer and within-wafer uniformity.

Exceptional Purity and Density

By minimizing gas-phase nucleation, LPCVD produces highly pure and dense films with fewer defects. The vacuum environment also inherently reduces the partial pressure of contaminants, ensuring that unwanted elements are not incorporated into the growing film.

Versatility in Materials

Like other CVD methods, LPCVD is highly versatile. It can be used to deposit a wide range of materials, including:

- Polycrystalline Silicon (Polysilicon)

- Silicon Nitride (Si₃N₄)

- Silicon Dioxide (SiO₂)

- Tungsten and other metals

The properties of these films, such as stress and electrical characteristics, can be precisely controlled by adjusting process parameters like temperature, gas flow, and pressure.

Understanding the Trade-offs

No process is perfect. The primary limitation of LPCVD is its requirement for high process temperatures, typically in the range of 500-900°C.

Temperature Constraints

These high temperatures are necessary to provide the energy needed for the chemical reactions to occur on the substrate surface.

This makes LPCVD unsuitable for coating temperature-sensitive materials, such as certain plastics or substrates with pre-existing metal layers (like aluminum) that have low melting points. In these cases, lower-temperature methods like Plasma-Enhanced CVD (PECVD) or Physical Vapor Deposition (PVD) are necessary.

Slower Deposition Rates

While batch efficiency is high, the deposition rate for a single substrate in LPCVD is typically lower than in atmospheric pressure CVD (APCVD). The process prioritizes controlled, uniform growth over raw speed.

Making the Right Choice for Your Goal

Selecting a deposition method requires aligning its capabilities with your primary objective.

- If your primary focus is the highest film quality, uniformity, and conformality on complex 3D structures: LPCVD is the definitive choice, especially for microfabrication and semiconductor applications.

- If your primary focus is coating a temperature-sensitive substrate: You must explore lower-temperature alternatives like PECVD or PVD sputtering.

- If your primary focus is achieving the fastest possible deposition rate on a simple, flat surface: A higher-pressure method like APCVD might be a more efficient solution.

Ultimately, choosing LPCVD is a strategic decision to prioritize exceptional film quality and batch efficiency for high-precision components.

Summary Table:

| Key Advantage | Description |

|---|---|

| Exceptional Film Uniformity | Superior wafer-to-wafer and within-wafer thickness control, ideal for batch processing. |

| High Purity & Density | Low-pressure environment minimizes gas-phase reactions and contaminants for fewer defects. |

| Excellent Conformality | Uniform coating on complex, high-aspect-ratio structures like trenches and sidewalls. |

| High Batch Throughput | Capable of processing hundreds of substrates simultaneously in a single run. |

| Material Versatility | Deposits a wide range of materials including polysilicon, silicon nitride, and metals. |

Ready to enhance your lab's thin-film deposition capabilities?

KINTEK specializes in providing high-quality lab equipment and consumables for demanding applications like LPCVD. Our solutions are designed to deliver the precision, purity, and uniformity your research or production requires.

Contact us today to discuss how our expertise can help you achieve superior results in microfabrication, semiconductor manufacturing, and MEMS development.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition