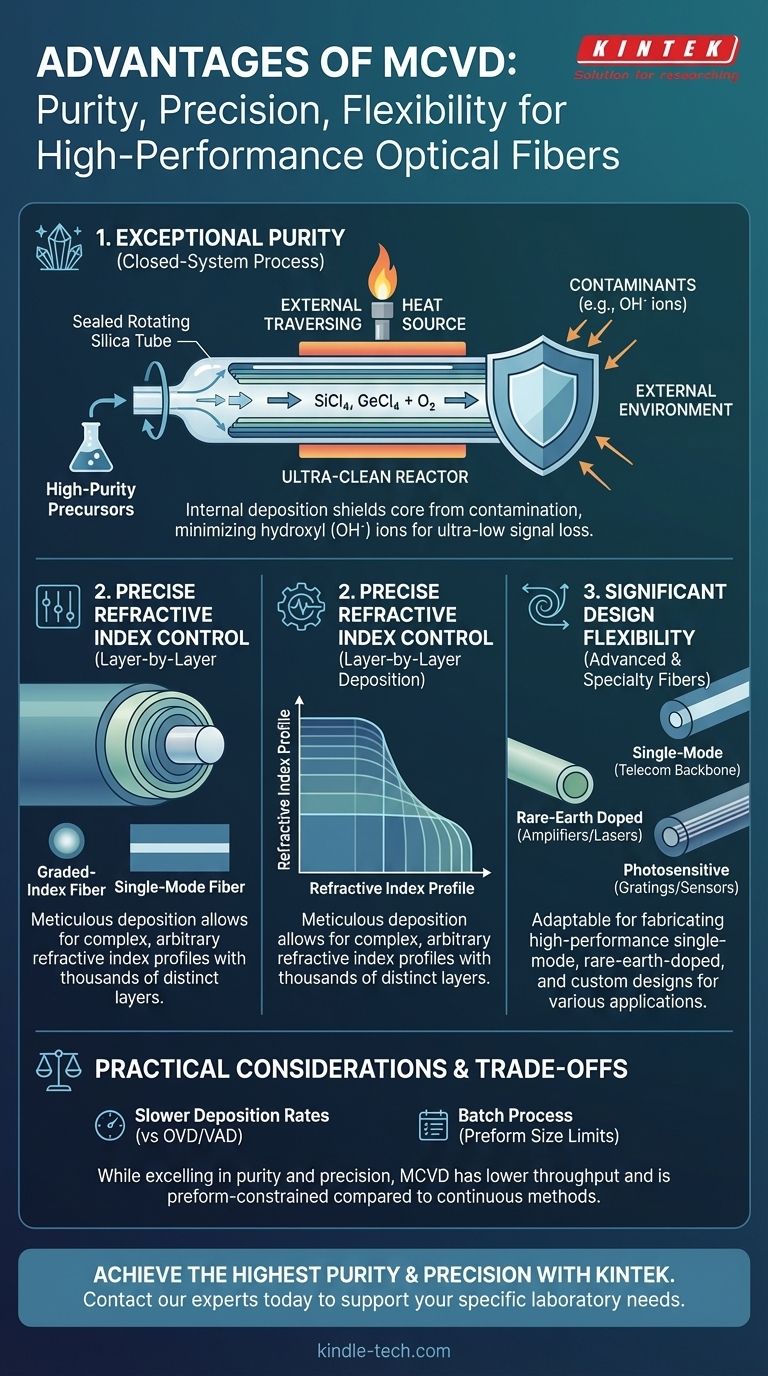

The primary advantages of Modified Chemical Vapor Deposition (MCVD) are the exceptional purity of the resulting glass, precise control over the refractive index profile, and significant flexibility in fiber design. This is achieved by using a closed-system process where deposition occurs inside a rotating silica tube, shielding the core materials from external contamination and allowing for meticulous layer-by-layer construction.

MCVD's core strength lies in its "inside-out" approach. By treating the substrate tube as a self-contained, ultra-clean reactor, it delivers the highest-purity glass and most precise profile control, making it the benchmark process for high-performance and specialty optical fibers.

The Core Principle: A Contamination-Free Internal Reactor

The fundamental design of the MCVD process is the source of its most significant advantages. It is an internal deposition method, which sets it apart from other common fabrication techniques.

How It Works

In MCVD, high-purity vapor-phase precursors, such as silicon tetrachloride (SiCl₄) and germanium tetrachloride (GeCl₄), are introduced with oxygen into a rotating, high-purity silica substrate tube. A traversing external heat source (like an oxy-hydrogen torch) heats the outside of the tube, causing the chemical precursors to react and deposit a thin layer of doped silica "soot" on the inner wall.

Eliminating External Contaminants

Because this entire reaction happens inside the sealed tube, the process is shielded from the ambient environment. This dramatically reduces the incorporation of contaminants, particularly hydroxyl (OH⁻) ions from water vapor, which are a primary cause of signal attenuation (loss) in optical fibers.

Ensuring Material Purity

The process uses vaporized metal halide precursors which can be distilled to extremely high levels of purity. This ensures that transition metal impurities, another source of signal absorption, are virtually nonexistent in the final deposited glass, leading to exceptionally low-loss fibers.

Unparalleled Control Over Fiber Properties

MCVD’s layer-by-layer deposition process provides a level of control that is difficult to achieve with other methods. This directly translates into superior performance and design flexibility.

Precise Refractive Index Profiling

The refractive index of each deposited layer is determined by the concentration of dopants (like Germanium) mixed into the gas stream. By precisely varying the gas mixture for each pass of the heat source, engineers can build complex and arbitrary refractive index profiles with hundreds or thousands of distinct layers. This control is critical for creating advanced graded-index fibers that minimize modal dispersion.

High-Performance Single-Mode Fibers

The ability to create exceptionally pure glass with a perfectly controlled index profile makes MCVD the standard for producing high-performance single-mode fibers. These are the fibers that form the backbone of long-haul telecommunications and submarine cable systems, where minimizing signal loss and dispersion is paramount.

Flexibility for Specialty Fibers

The same process control makes MCVD highly adaptable for fabricating specialty fibers. By introducing different precursors, it's possible to create rare-earth-doped fibers for amplifiers and lasers (e.g., Erbium-doped), photosensitive fibers for gratings, and other custom designs for sensing and research applications.

Understanding the Trade-offs

No process is perfect. While MCVD excels in purity and precision, it has practical limitations that are important to understand.

Slower Deposition Rates

Compared to outside deposition methods like OVD (Outside Vapor Deposition) and VAD (Vapor Axial Deposition), MCVD generally has a lower deposition rate. The process is inherently limited by the heat transfer through the substrate tube wall.

Batch Process and Throughput

MCVD is a batch process. Each preform is made one at a time from an individual tube. This can limit manufacturing throughput compared to more continuous or larger-batch methods.

Preform Size Limitations

The final size of the fiber preform is constrained by the starting dimensions of the silica substrate tube. Other methods can build up much larger preforms, which can then be drawn into a greater length of fiber, leading to better economies of scale.

Making the Right Choice for Your Goal

Selecting a fabrication method depends entirely on the technical and economic requirements of the final product.

- If your primary focus is ultimate performance and minimal signal loss: MCVD is the definitive choice for telecom-grade, single-mode, and specialty fibers where purity and profile control cannot be compromised.

- If your primary focus is creating complex or novel fiber designs: The precise layer-by-layer control of MCVD makes it the ideal platform for research, development, and advanced graded-index fiber production.

- If your primary focus is high-volume, cost-effective multimode fiber: Alternative methods like OVD or VAD are often preferred for their higher deposition rates and ability to produce larger preforms.

MCVD remains a cornerstone of the optical fiber industry because it offers an unmatched combination of purity and precision, enabling the creation of the world's most advanced optical waveguides.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Exceptional Purity | Closed-system process minimizes contamination (e.g., OH⁻ ions), leading to ultra-low signal loss. |

| Precise Index Control | Layer-by-layer deposition allows for complex, arbitrary refractive index profiles. |

| Design Flexibility | Ideal for high-performance single-mode and specialty fibers (e.g., rare-earth-doped). |

| Trade-off | Consideration |

| Slower Deposition | Lower throughput compared to OVD/VAD methods. |

| Batch Process | Limited by preform size and individual tube processing. |

Ready to achieve the highest purity and precision in your optical fiber research or production?

KINTEK specializes in providing the high-purity laboratory equipment and consumables essential for advanced fabrication processes like MCVD. Our materials and solutions support the creation of low-loss, high-performance optical fibers.

Contact our experts today to discuss how we can support your specific laboratory needs and help you build the next generation of optical waveguides.

Visual Guide

Related Products

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- How are optical coatings applied? Achieve Precision with Advanced Vacuum Deposition Methods

- What are the precursors used in CVD synthesis of graphene? Key Choices for High-Quality Growth

- What is the function of high-temperature metal filaments in HFCVD? Catalyzing Diamond Growth Success

- What equipment requirements arise when using halogenated precursor gases? Protect Your SiC Deposition Furnaces

- What are the advantages of chemical vapor deposition? Achieve Superior Thin Films for Your Lab

- What is the difference between bio-oil and biochar? Choose the Right Biomass Product for Your Goals

- What are the applications of chemical Vapour deposition method? Achieve High-Performance Thin Films

- What is physical vapor deposition used for? Enhancing Durability, Function, and Appearance