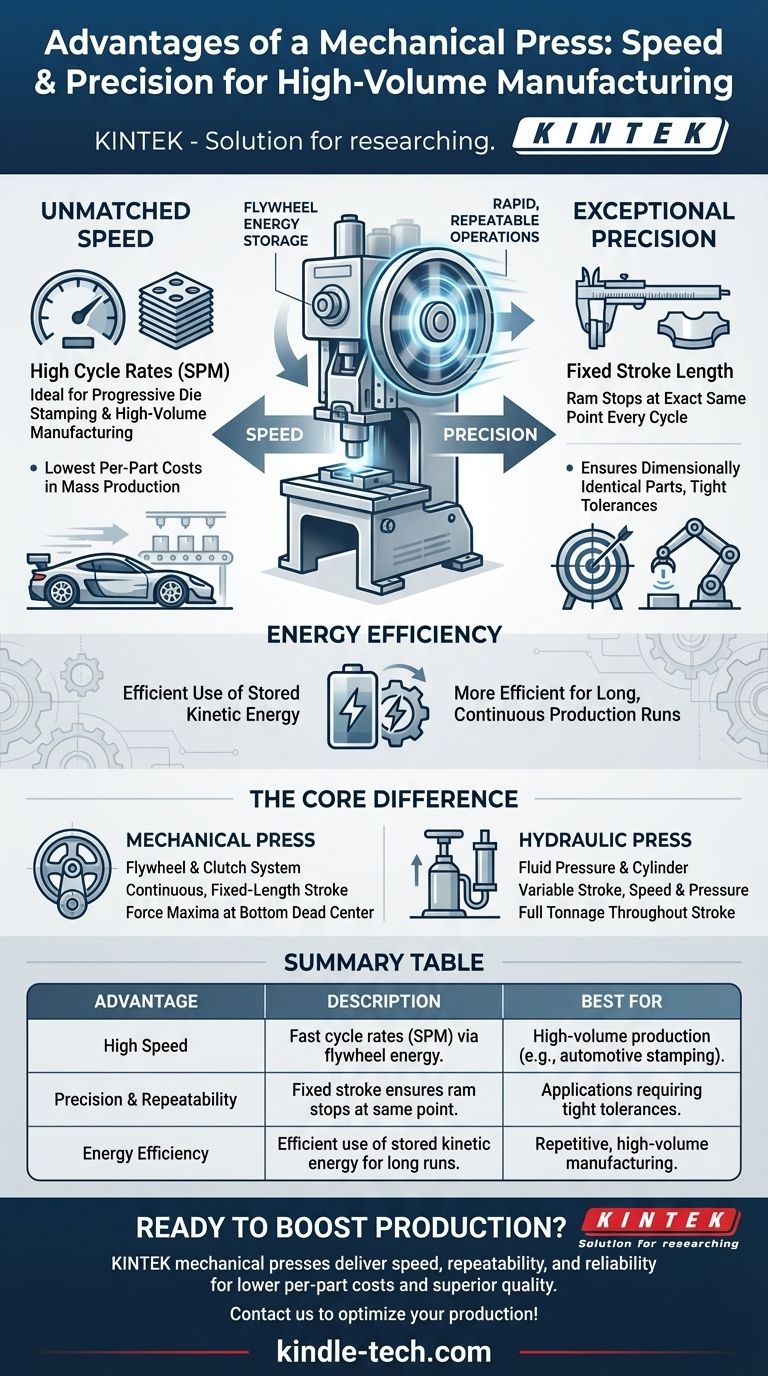

At its core, a mechanical press offers two primary advantages: speed and precision. For manufacturing environments that require high-volume production with extreme consistency, the design of a mechanical press is unmatched. Its fixed stroke cycle allows for rapid, repeatable operations that are essential for industries like automotive stamping and electronics manufacturing.

The choice between a mechanical and a hydraulic press is not about which is universally superior, but about aligning the machine's core strengths with your specific application. Mechanical presses excel at high-speed, repetitive tasks, while hydraulic presses offer superior control and force flexibility.

The Core Difference: How Force is Applied

The fundamental advantages and disadvantages of each press type stem directly from their method of generating force. Understanding this mechanism is key to choosing the right tool.

Mechanical Presses: The Power of the Flywheel

A mechanical press uses a motor to spin a heavy flywheel, which stores kinetic energy. When engaged, a clutch connects this flywheel to a crank and ram system, driving the tool down in a continuous, fixed-length stroke.

This design is inherently fast and consistent, as the ram's movement is determined by the mechanical linkage.

Hydraulic Presses: The Control of Fluid Pressure

In contrast, a hydraulic press uses a pump to move incompressible fluid into a cylinder, pushing a piston and ram down. The force is generated by fluid pressure.

This system allows for variable stroke length, speed, and pressure at any point during the operation, offering a high degree of control.

Key Advantages of a Mechanical Press

For the right application, the benefits of a mechanical press are significant and lead to lower per-part costs in mass production.

Unmatched Speed for High-Volume Production

The defining advantage is its high cycle rate, or strokes per minute (SPM). Because the energy is stored in the flywheel, the press can cycle incredibly quickly.

This makes it the ideal choice for progressive die stamping and other high-volume manufacturing processes where output is paramount.

Exceptional Precision and Repeatability

The stroke of a mechanical press has a fixed bottom dead center. This means the ram stops at the exact same point with every single cycle.

This inherent repeatability ensures every part produced is dimensionally identical, which is critical for maintaining tight tolerances in precision components.

Energy Efficiency in Repetitive Cycles

Once the flywheel is spinning at its operational speed, the energy required to perform each stamping operation is relatively low.

The system efficiently uses its stored kinetic energy, making it more energy-efficient for long, continuous production runs compared to a hydraulic pump that must run constantly.

Understanding the Trade-offs: Where Hydraulic Presses Excel

To fully appreciate the strengths of a mechanical press, it's crucial to understand where its counterpart has the advantage. The simplicity and control of hydraulic systems make them a better fit for different tasks.

Superior Force Control and Flexibility

As noted in the provided analysis, hydraulic presses offer easy control of press forces and speeds. The operator can adjust the tonnage and ram speed at any point in the stroke.

Mechanical presses, by contrast, deliver maximum force only at the very bottom of the stroke, offering little to no flexibility during the cycle.

Lower Initial Cost and Simpler Maintenance

Hydraulic systems are generally cheaper to purchase and contain fewer moving parts than the complex clutch and brake systems of a mechanical press.

This simplicity also means they are often easier to maintain and less prone to catastrophic mechanical breakdowns.

Quieter and Safer Operation

The smooth application of fluid pressure makes hydraulic presses significantly quieter than the high-impact operation of a mechanical press. This can lead to a better and safer working environment.

Making the Right Choice for Your Application

Selecting the correct press is a critical decision based entirely on your production goals.

- If your primary focus is high-volume, low-variation parts: The speed and repeatability of a mechanical press will deliver the lowest cost per piece.

- If your primary focus is deep-drawing or forming complex shapes: The full tonnage and precise control throughout the stroke make a hydraulic press the superior choice.

- If your primary focus is budget-friendliness and application flexibility: A hydraulic press offers a lower barrier to entry and can be adapted to a wider variety of jobs.

Ultimately, aligning the machine's inherent design with your specific manufacturing need is the key to a successful investment.

Summary Table:

| Advantage | Description | Best For |

|---|---|---|

| High Speed | Fast cycle rates (SPM) due to flywheel energy storage. | High-volume production (e.g., automotive stamping). |

| Precision & Repeatability | Fixed stroke ensures the ram stops at the exact same point every cycle. | Applications requiring tight tolerances and consistent parts. |

| Energy Efficiency | Efficient use of stored kinetic energy for long, continuous runs. | Repetitive, high-volume manufacturing processes. |

Ready to boost your production line's efficiency and precision?

KINTEK specializes in high-performance lab and manufacturing equipment. Our mechanical presses are engineered to deliver the speed, repeatability, and reliability your high-volume operations demand, helping you achieve lower per-part costs and superior product quality.

Contact us today via our [#ContactForm] to discuss how a KINTEK mechanical press can be the cornerstone of your manufacturing success. Let's optimize your production together!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy