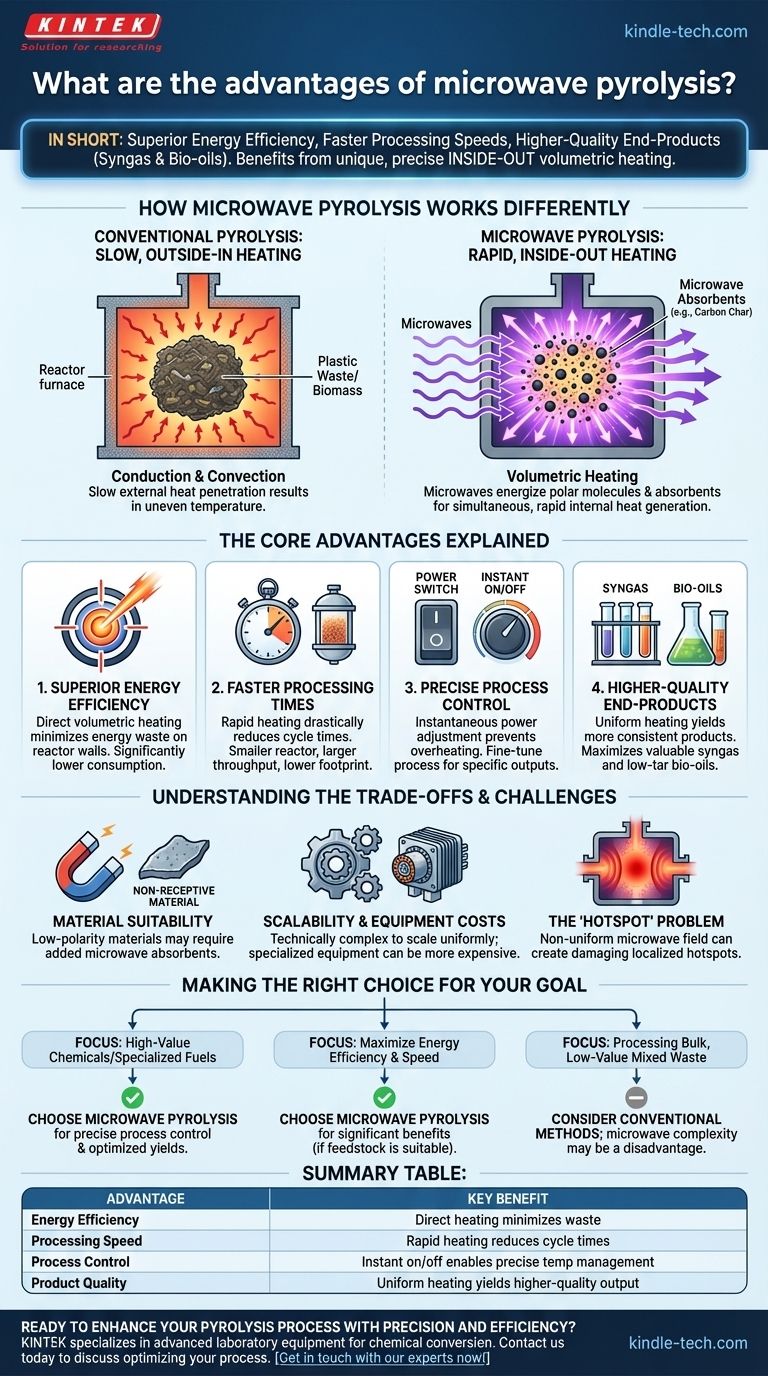

In short, the primary advantages of microwave pyrolysis are its superior energy efficiency, significantly faster processing speeds, and the ability to produce higher-quality end-products like syngas and bio-oils. These benefits stem from its unique method of heating materials from the inside out, offering a level of precision that traditional methods cannot match.

The core advantage of microwave pyrolysis isn't just that it uses a different energy source; it's that it fundamentally changes how the material is heated. This shift from slow, external heating to rapid, internal heating provides granular control over the chemical reactions, leading to more efficient and valuable outcomes.

How Microwave Pyrolysis Works Differently

To understand its advantages, you must first grasp how its heating mechanism differs from the furnaces used in conventional pyrolysis.

Conventional Pyrolysis: Slow, Outside-In Heating

Conventional pyrolysis relies on conduction and convection. The walls of a reactor are heated, and that heat slowly transfers to the surface of the feedstock (like plastic waste or biomass).

The energy must then gradually penetrate from the outside of the material to its core. This process is slow and often results in uneven temperature distribution.

Microwave Pyrolysis: Rapid, Inside-Out Heating

Microwave pyrolysis uses volumetric heating. Microwaves pass through the material and directly energize polar molecules within it, causing them to vibrate and generate heat simultaneously throughout the entire volume.

This is analogous to how a microwave oven heats food much faster than a conventional oven. Heat is generated everywhere at once, rather than seeping in from the surface.

The Role of Microwave Absorbents

Not all materials absorb microwave energy efficiently. To overcome this, a highly receptive material like carbon char or silicon carbide is often mixed with the feedstock.

This "absorbent" heats up extremely rapidly, initiating and accelerating the pyrolysis of the surrounding, less-receptive material.

The Core Advantages Explained

This unique heating mechanism translates directly into four key operational benefits.

1. Superior Energy Efficiency

Because microwaves heat the feedstock directly, very little energy is wasted heating the reactor chamber itself. All the energy is focused precisely where it's needed.

This targeted approach results in significantly lower overall energy consumption compared to heating a massive, conventional furnace.

2. Faster Processing Times

Volumetric heating is exceptionally rapid, drastically reducing the time required to bring the feedstock to the target pyrolysis temperature.

This means a smaller microwave reactor can achieve the same throughput as a much larger conventional system, leading to a smaller operational footprint and potentially lower capital costs.

3. Precise Process Control

Microwave power can be adjusted or turned off instantly. This provides an unparalleled level of temperature control that is impossible with conventional furnaces, which retain heat long after the energy source is shut off.

This precision prevents overheating and minimizes undesirable secondary reactions, allowing operators to fine-tune the process for specific outputs.

4. Higher-Quality End-Products

The combination of uniform heating and precise control leads to a more consistent and higher-quality product slate.

For example, it can maximize the yield of valuable syngas (a mixture of hydrogen and carbon monoxide) or produce bio-oils with a more favorable chemical composition and lower tar content.

Understanding the Trade-offs and Challenges

No technology is a universal solution. It's critical to understand the limitations of microwave pyrolysis to determine if it's the right fit for your application.

Material Suitability

Materials with low polarity, such as certain plastics or very dry biomass, do not absorb microwave energy well. This makes the use of a microwave absorbent essential, adding a step to the process.

Scalability and Equipment Costs

Designing large-scale microwave reactors that ensure an even distribution of microwave energy is technically complex. The specialized equipment, such as industrial magnetrons and waveguides, can also be more expensive than simpler conventional heating elements.

The "Hotspot" Problem

If the microwave field within the reactor is not uniform, it can create hotspots—areas of intense, localized heating. These can lead to inconsistent product quality and damage to the reactor if not managed through proper engineering and design.

Making the Right Choice for Your Goal

Ultimately, the decision to use microwave pyrolysis depends on your specific feedstock and desired outcome.

- If your primary focus is high-value chemicals or specialized fuels: The precise process control offered by microwave pyrolysis is a decisive advantage for optimizing yields.

- If your primary focus is maximizing energy efficiency and processing speed: Microwave pyrolysis offers clear and significant benefits over conventional methods, provided your feedstock is suitable.

- If your primary focus is processing bulk, low-value mixed waste: The added complexity and cost of microwave systems may be a disadvantage compared to simpler, more robust conventional furnaces.

Understanding that microwave pyrolysis is a tool for precision chemical conversion, not just bulk heating, is the key to leveraging its full potential.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Energy Efficiency | Direct, volumetric heating minimizes energy waste. |

| Processing Speed | Rapid inside-out heating drastically reduces cycle times. |

| Process Control | Instant on/off power enables precise temperature management. |

| Product Quality | Uniform heating yields higher-quality syngas and bio-oils. |

Ready to enhance your pyrolysis process with precision and efficiency?

KINTEK specializes in advanced laboratory equipment for chemical conversion and material processing. If you are researching or developing pyrolysis applications for waste conversion, bio-fuel production, or chemical synthesis, our expertise can help you achieve superior results.

Contact us today to discuss how our solutions can bring the benefits of controlled, efficient heating to your lab. Let's optimize your process together.

Get in touch with our experts now!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What temperature is alumina activated? Unlock Optimal Porosity for Adsorption

- What are the common applications for a tube furnace? Essential for Heat Treatment, Synthesis, and Purification

- What is the ceramic tube high temperature? From 1100°C to 1800°C, Choose the Right Material

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning