At its core, a mini hydraulic press offers the precision and repeatability of a full-sized hydraulic system in a compact, affordable, and easy-to-use form factor. It is specifically designed for environments like laboratories where space is limited, but sample consistency is critical for reliable testing.

The primary advantage is not just its small size, but its ability to deliver quantifiable, repeatable pressure. This capability transforms sample preparation from an inconsistent art into a reliable science, directly improving the quality of analytical results.

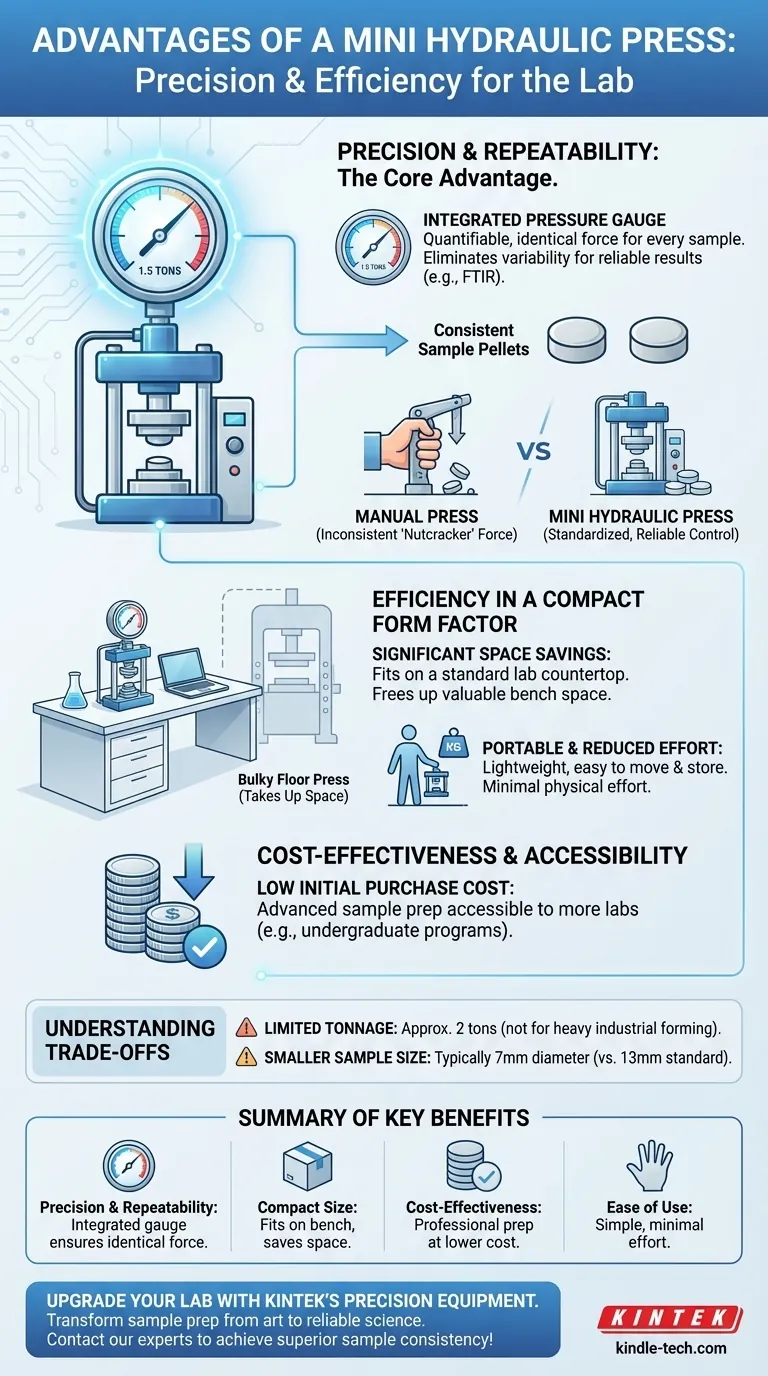

Precision and Repeatability: The Core Functional Advantage

The most significant benefit of a mini hydraulic press is its ability to produce identical samples time after time. This consistency is the foundation of reliable scientific testing.

The Role of the Integrated Pressure Gauge

A key feature of a mini hydraulic press is its pressure gauge. This allows the user to apply a precise and quantifiable load to every sample.

By ensuring the same pressure is used for each pellet, the machine eliminates a major source of variability in sample preparation.

Superior to Manual Alternatives

Simple hand presses, which often operate like a nutcracker, lack any method for standardizing applied force. This leads to inconsistent sample density and thickness.

A mini hydraulic press solves this problem, providing a level of control that manual tools cannot match, ensuring every sample is produced under identical conditions.

Impact on Testing Reliability

This repeatability is especially critical for analytical techniques like FTIR (Fourier-transform infrared) spectroscopy.

Consistent and uniform sample pellets ensure that the test results are reliable and comparable, as the physical properties of the sample are no longer a variable.

Efficiency in a Compact Form Factor

Beyond precision, the design of a mini hydraulic press is optimized for the practical constraints of a laboratory or workshop.

Significant Space Savings

These machines are designed to sit on a standard lab countertop. Their small footprint frees up valuable bench space compared to bulky, full-sized presses.

Portability and Reduced Effort

Typically weighing only a few kilograms, a mini press is easy to move and store. It also requires far less physical effort to operate than manually pumped standard presses.

Cost-Effectiveness

With a simpler design and fewer parts, mini hydraulic presses have a low initial purchase cost. This makes advanced sample preparation technology accessible to a wider range of labs, including undergraduate chemistry programs.

Understanding the Trade-offs

While highly advantageous for its intended purpose, a mini press is not a replacement for all other press types. Understanding its limitations is key to making an informed choice.

Limited Tonnage and Capacity

Despite being powerful for its size—often delivering up to 2 tons of force—a mini press cannot match the immense pressure generated by large, industrial hydraulic presses. It is not suited for heavy-duty manufacturing or forming operations.

Smaller Sample Size

Mini presses are designed to produce smaller pellets, typically around 7 mm in diameter. This is smaller than the 13 mm standard produced by many larger presses. For applications requiring larger samples, a mini press would not be suitable.

Making the Right Choice for Your Goal

Selecting the correct press depends entirely on your specific requirements for precision, scale, and budget.

- If your primary focus is consistent, reliable samples in a lab setting: The mini hydraulic press is the optimal choice due to its pressure gauge, compact size, and ease of use.

- If your primary focus is maximum force for industrial applications: A full-sized hydraulic press is necessary to achieve the high tonnage required for large-scale work.

- If your primary focus is the lowest possible cost for non-critical tasks: A simple hand press may suffice, but you will sacrifice the repeatability needed for reliable analytical testing.

Ultimately, the mini hydraulic press excels by providing a professional, data-driven approach to sample preparation in a package perfectly sized for the modern laboratory.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Precision & Repeatability | Integrated pressure gauge ensures identical force for every sample. |

| Compact Size | Fits on a standard lab bench, saving valuable space. |

| Cost-Effectiveness | Professional sample prep at a lower initial cost than full-sized presses. |

| Ease of Use | Simple operation with minimal physical effort required. |

Upgrade your lab's sample preparation with KINTEK's precision equipment.

A mini hydraulic press from KINTEK transforms your sample prep from an inconsistent art into a reliable science, delivering the quantifiable pressure control needed for accurate analytical results like FTIR spectroscopy. Our lab equipment is designed for researchers and technicians who demand consistency, efficiency, and value.

Ready to achieve superior sample consistency? Contact our experts today to find the perfect press for your laboratory's needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Lab Heat Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy