In dentistry, porcelain crowns offer a compelling combination of lifelike aesthetics and reliable function for restoring a damaged tooth. Their primary advantages lie in their ability to perfectly mimic the color and translucency of natural enamel, while also being durable, stain-resistant, and highly biocompatible with gum tissue.

While porcelain's aesthetic superiority is its most famous trait, the crucial decision involves balancing this visual benefit against the specific location in the mouth and the biting forces the crown must endure.

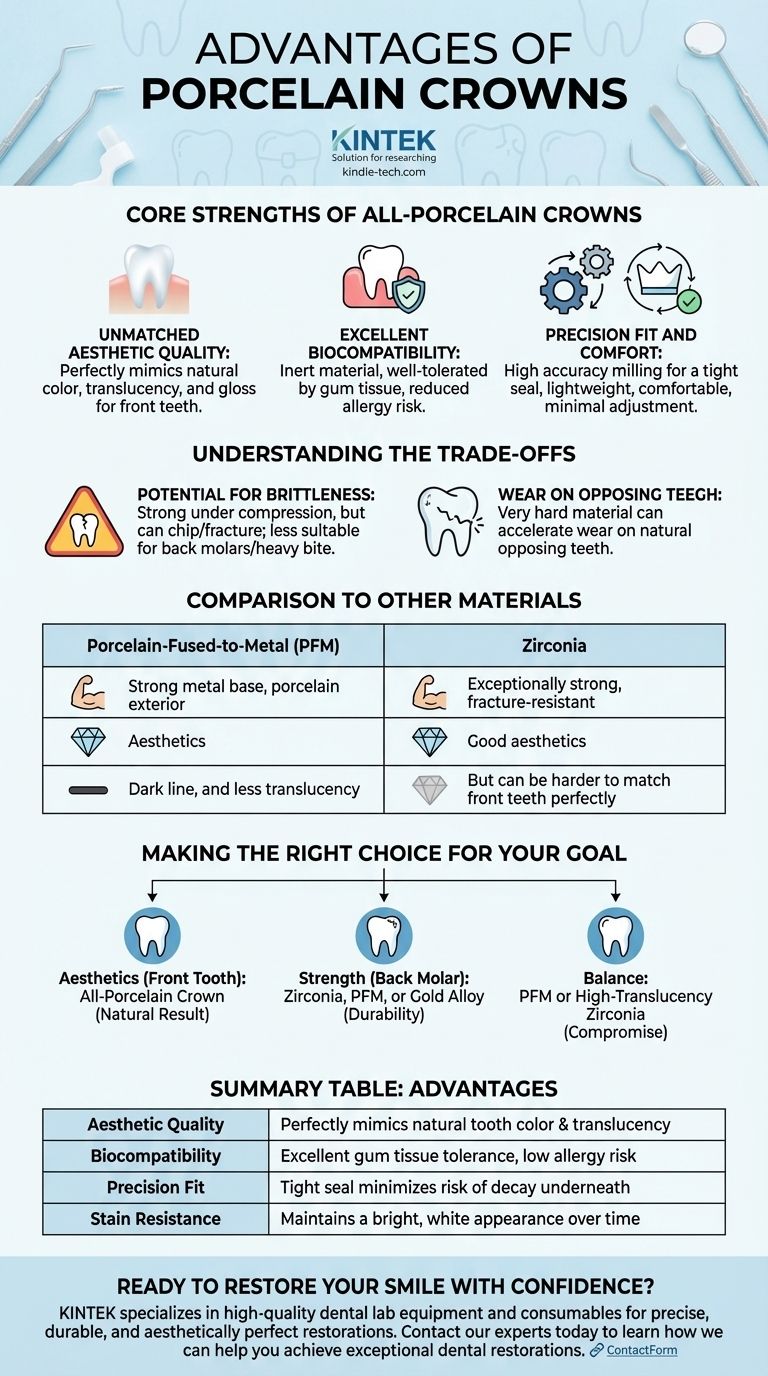

The Core Strengths of All-Porcelain Crowns

When a dentist recommends an all-porcelain (or all-ceramic) crown, they are leveraging several key material properties that benefit the patient both visually and functionally.

Unmatched Aesthetic Quality

A porcelain crown's greatest strength is its ability to replicate a natural tooth. The material can be layered and tinted to match the exact shade, translucency, and gloss of your surrounding teeth.

This makes it the premier choice for highly visible teeth, particularly the front incisors and canines, where a seamless appearance is paramount.

Excellent Biocompatibility

Porcelain is an inert material, meaning it is exceptionally well-tolerated by the soft tissues of the mouth. This significantly reduces the risk of gum irritation or allergic reactions that can sometimes occur with the metals used in other crown types.

Precision Fit and Comfort

Modern dental technology allows for the design and milling of porcelain crowns with incredible accuracy. This precision fit ensures a tight seal against the prepared tooth, minimizing the risk of future decay underneath the crown.

The material is also lightweight and easy for a dental lab to shape, contributing to a comfortable final restoration that feels natural in your mouth and requires minimal adjustment time.

Understanding the Trade-offs

No single dental material is perfect for every situation. Being an informed patient means understanding the limitations of porcelain just as well as its benefits.

Potential for Brittleness

While porcelain is very strong under compressive (chewing) forces, it is more brittle than metal or zirconia. This means it can be more prone to chipping or fracturing under specific types of stress.

For this reason, all-porcelain crowns may not be the first choice for back molars in patients who grind their teeth (bruxism) or have a particularly heavy bite.

Wear on Opposing Teeth

Dental porcelain is a very hard material, sometimes even harder than natural tooth enamel. Over many years, a porcelain crown can cause accelerated wear on the natural tooth it bites against.

Your dentist will evaluate your specific bite pattern to determine if this is a significant concern for your case.

Comparison to Other Materials

Porcelain-Fused-to-Metal (PFM) crowns offer a middle ground, with a strong metal substructure and a porcelain exterior. They are stronger than all-porcelain but can sometimes show a dark line at the gum and lack the superior translucency of an all-ceramic crown.

Zirconia, another type of ceramic, is exceptionally strong and fracture-resistant, making it a go-to choice for molars. While modern zirconia has excellent aesthetics, it can still be difficult to match the nuanced, lifelike appearance of a masterfully crafted porcelain crown for a front tooth.

Making the Right Choice for Your Goal

The "best" crown material is entirely dependent on your specific clinical needs and personal priorities.

- If your primary focus is aesthetics for a front tooth: An all-porcelain crown is almost always the superior choice for the most natural, undetectable result.

- If your primary focus is strength for a back molar: A zirconia, PFM, or even a gold alloy crown is often recommended for its superior durability and fracture resistance.

- If your primary focus is balancing strength and aesthetics: A PFM or modern high-translucency zirconia crown may offer the ideal compromise for your situation.

Equipped with this understanding, you can work with your dentist to select the material that best aligns with your long-term dental health and aesthetic goals.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Aesthetic Quality | Perfectly mimics natural tooth color & translucency |

| Biocompatibility | Excellent gum tissue tolerance, low allergy risk |

| Precision Fit | Tight seal minimizes risk of decay underneath |

| Stain Resistance | Maintains a bright, white appearance over time |

Ready to restore your smile with confidence?

Understanding the advantages of porcelain crowns is the first step. The next is partnering with a trusted provider for your dental laboratory needs. KINTEK specializes in high-quality dental lab equipment and consumables, helping dental professionals create precise, durable, and aesthetically perfect restorations like porcelain crowns.

Whether you are a dental lab technician focused on crafting lifelike crowns or a dentist seeking reliable materials for your practice, KINTEK's products support superior outcomes for your patients.

Contact our experts today to learn how we can help you achieve exceptional dental restorations.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag