At its core, thermal evaporation's primary advantages are its simplicity, speed, and cost-effectiveness. It is one of the most straightforward Physical Vapor Deposition (PVD) methods, serving as a foundational technique for depositing thin films of materials with relatively low melting points, such as gold, chromium, or aluminum.

While often seen as a basic deposition method, thermal evaporation's value is not in its sophistication, but in its efficiency. It provides a fast, inexpensive, and highly directional deposition path, making it the optimal choice for specific applications where ultimate film purity is not the primary concern.

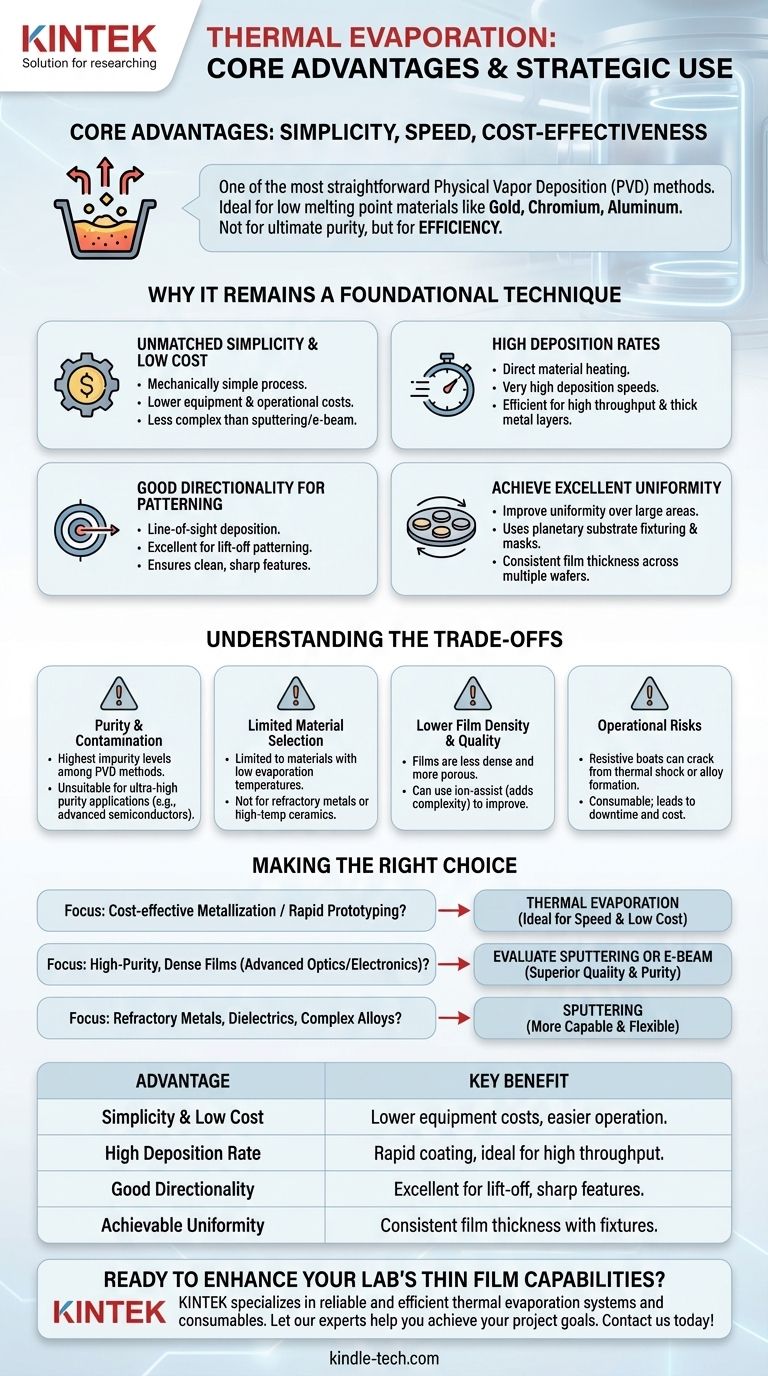

Why It Remains a Foundational Technique

Thermal evaporation’s persistence in both research and production environments is due to a compelling set of practical benefits. It excels when the goal is to deposit a simple film quickly and inexpensively.

Unmatched Simplicity and Low Cost

The process is mechanically simple: a current is passed through a resistive "boat" or filament containing the source material. This heating causes the material to sublimate or evaporate, coating a substrate in the vacuum chamber.

This simplicity translates directly to lower equipment costs and less complex operation compared to methods like sputtering or e-beam evaporation.

High Deposition Rates

Because the material is heated directly to its evaporation point, thermal evaporation can achieve very high deposition rates. This speed makes it highly efficient for processes where throughput is a key factor, such as coating large batches of samples or creating thick metal layers.

Good Directionality for Patterning

The evaporated material travels in a straight line from the source to the substrate. This "line-of-sight" deposition is highly directional, which is a significant advantage for processes like lift-off patterning.

Good directionality ensures clean, sharp features because the evaporated material does not coat the sidewalls of the photoresist.

Can Achieve Excellent Uniformity

While a simple point source is not inherently uniform over a large area, uniformity can be dramatically improved. Using planetary substrate fixturing (which rotates and revolves substrates) and carefully designed uniformity masks, thermal evaporation can achieve excellent film thickness consistency across multiple wafers.

Understanding the Trade-offs

The simplicity that makes thermal evaporation attractive also introduces critical limitations. Understanding these trade-offs is essential to choosing the right tool for the job.

The Purity and Contamination Problem

Thermal evaporation generally produces films with the highest impurity levels among common PVD methods. The hot filament or boat can outgas or even co-evaporate, introducing contaminants into the film.

This makes it unsuitable for applications demanding ultra-high purity, such as in advanced semiconductor manufacturing.

Limited Material Selection

The technique is fundamentally limited to materials that can be evaporated at temperatures the resistive boat can withstand without failing. It works well for metals with low melting points like Au, Cr, and Ge.

However, it is not suitable for refractory metals (like tungsten or tantalum) or many ceramic compounds that require extremely high temperatures to vaporize.

Lower Film Density and Quality

Films deposited via thermal evaporation tend to be less dense and more porous than those created with higher-energy processes like sputtering. This can affect their mechanical and optical properties.

This limitation can be partially overcome by using an ion-assist source, which bombards the growing film with ions to increase its density, but this adds complexity and cost.

Operational Risks: Boat Cracking

The resistive boats are consumable and subject to failure. Thermal shock, caused by ramping power up or down too quickly, can crack the boat.

Furthermore, some evaporants can form alloys with the boat material at high temperatures, causing it to become brittle and crack. A cracked boat must be discarded, leading to downtime and material cost.

Making the Right Choice for Your Goal

Selecting thermal evaporation is a strategic decision based on your specific technical and budget requirements.

- If your primary focus is cost-effective metallization or rapid prototyping: Thermal evaporation is often the ideal choice due to its speed and low operational overhead.

- If your primary focus is creating high-purity, dense films for advanced optics or electronics: You should evaluate sputtering or electron-beam evaporation, which offer superior film quality and purity.

- If your primary focus is depositing refractory metals, dielectrics, or complex alloys: Thermal evaporation is unsuitable; sputtering is the far more capable and flexible alternative.

Ultimately, its value lies in knowing exactly when its straightforward approach is a strategic advantage.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Simplicity & Low Cost | Lower equipment costs and easier operation than other PVD methods. |

| High Deposition Rate | Rapid coating, ideal for high throughput and thick metal layers. |

| Good Directionality | Excellent for lift-off patterning, creating sharp, clean features. |

| Achievable Uniformity | Planetary fixtures and masks enable consistent film thickness. |

Ready to enhance your lab's thin film capabilities?

KINTEK specializes in providing reliable and efficient thermal evaporation systems and consumables. Whether you're focused on rapid prototyping, cost-effective metallization, or specific research applications, our expertise ensures you get the right solution for your laboratory needs.

Contact us today to discuss how our thermal evaporation equipment can streamline your deposition process. Get in touch via our contact form and let our experts help you achieve your project goals.

Visual Guide

Related Products

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- What are the uses of evaporation in industry? From Food Concentration to High-Tech Thin Films

- How is film thickness controlled in evaporation systems? Master Deposition Rate, Time, and Geometry

- What are the advantages of using Monel alloy reactors and nickel sample boats? Secure Purity in Carbon Fluorination

- What are the disadvantages of thermal evaporation method? Key Limitations in Purity and Performance

- What are the applications of evaporation in industries? From Wastewater to Electronics

- What are the applications of thermal evaporation? A Guide to Thin-Film Deposition for Electronics & Coatings

- What is thermal vapour deposition? A Simple Guide to PVD Coating Technology

- How is film thickness controlled in evaporation? Achieve Nanometer Precision with Quartz Crystal Monitoring