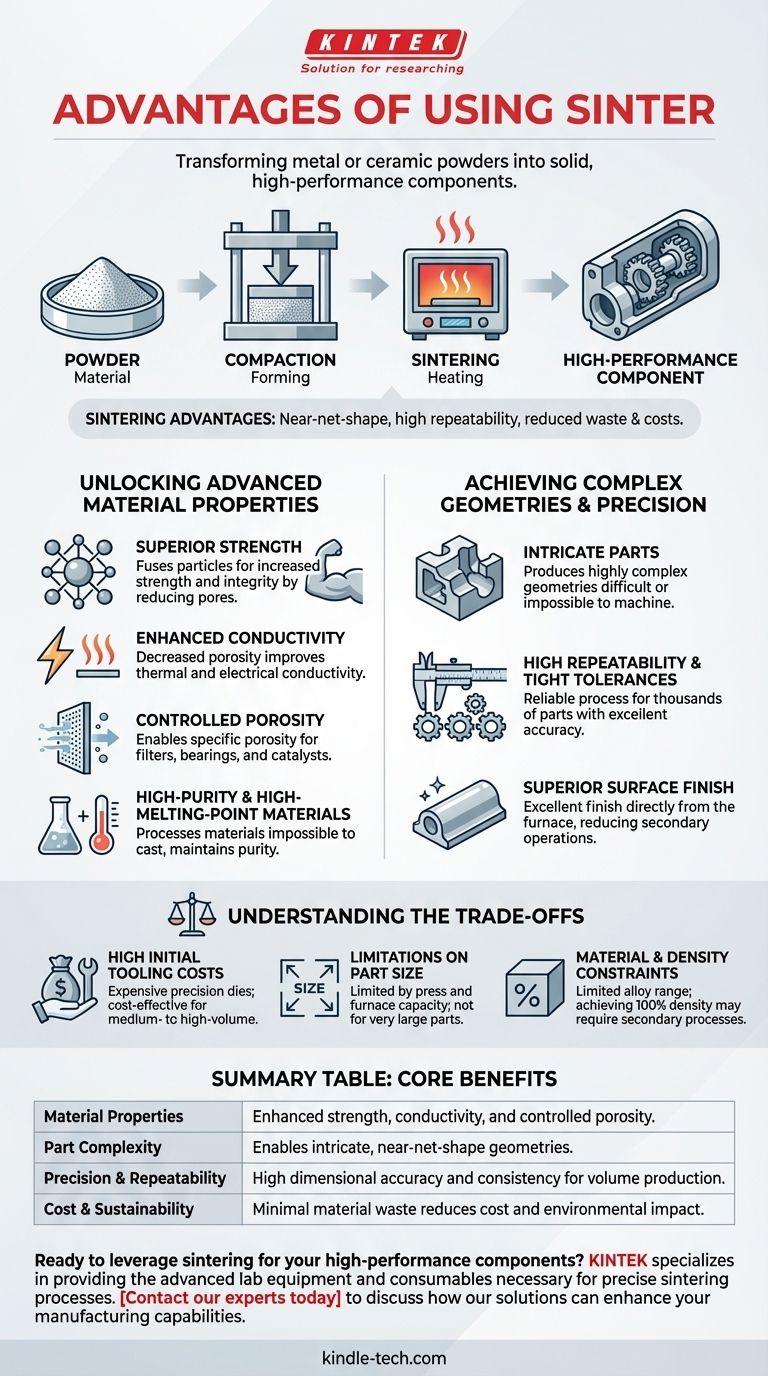

Sintering offers significant advantages in manufacturing by transforming metal or ceramic powders into solid, high-performance components. The process enables the creation of strong, complex parts with high precision and minimal waste, often from materials that are difficult to work with using traditional methods like machining or casting.

Sintering is more than a simple heating process; it is a strategic manufacturing choice that unlocks unique material properties and complex geometries. Its primary value lies in its ability to create near-net-shape parts with high repeatability, reducing both material waste and post-processing costs.

Unlocking Advanced Material Properties

The core of sintering is the atomic diffusion that occurs when particles are heated below their melting point. This fundamental mechanism is responsible for dramatic improvements in the final component's characteristics.

Fusing Particles for Superior Strength

By heating compacted powder, sintering encourages the growth of "necks" between individual particles. This process reduces the internal pores, effectively fusing the powder into a solid, coherent mass with significantly increased strength and integrity.

Enhancing Thermal and Electrical Conductivity

As the porosity within the material decreases, the contact area between particles increases. This creates a more direct path for heat and electricity to travel, leading to enhanced thermal and electrical conductivity in the final part.

Controlling Porosity for Specific Applications

While sintering is often used to create high-density parts, it can also be precisely controlled to create components with a specific, engineered level of porosity. This is critical for applications like self-lubricating bearings, filters, and catalysts where fluid or gas permeability is a required feature.

Enabling High-Purity and High-Melting-Point Materials

Sintering is exceptionally well-suited for materials with very high melting points, which are often impossible to process via casting. It also maintains high material purity by avoiding the contaminants that can be introduced during melting processes.

Achieving Complex Geometries with High Precision

Sintering liberates designers from many of the constraints of traditional subtractive manufacturing, where material is cut away from a solid block.

From Powder to Intricate Part

Because the initial shape is formed by compacting powder in a die, sintering can produce highly complex and intricate geometries that would be difficult, expensive, or impossible to machine. This includes internal features, undercuts, and non-machinable shapes.

Ensuring High Repeatability and Tight Tolerances

Sintering is a highly reliable and repeatable process. Once the tooling and process parameters are established, it can produce thousands or millions of parts with excellent dimensional accuracy and consistent properties, ensuring good tolerance control.

Superior Surface Finish Out of the Furnace

Sintered parts often have an excellent surface finish directly after the process is complete. This can reduce or entirely eliminate the need for secondary finishing operations like grinding or polishing, saving time and cost.

Understanding the Trade-offs

While powerful, sintering is not a universal solution. Understanding its limitations is key to using it effectively.

High Initial Tooling Costs

Creating the high-precision dies and tooling required for powder compaction can be expensive. This upfront investment means sintering is typically most cost-effective for medium- to high-volume production runs where the cost can be amortized across many parts.

Limitations on Part Size

The size of components that can be sintered is limited by the capacity of the compaction presses and the size of the sintering furnaces. It is generally not suitable for producing very large parts.

Material and Density Constraints

While versatile, the range of alloys suitable for sintering is more limited than for casting or machining. Furthermore, achieving 100% theoretical density can be difficult without secondary operations like hot isostatic pressing (HIP).

Making the Right Choice for Your Application

Selecting sintering depends on your specific priorities regarding complexity, volume, material properties, and cost.

- If your primary focus is complex, small parts in high volume: Sintering is an excellent choice due to its near-net-shape capability and economic efficiency at scale.

- If your primary focus is material performance: Sintering allows for precise alloying and density control to enhance properties like strength, conductivity, or controlled porosity.

- If your primary focus is cost reduction and sustainability: The minimal material waste inherent in the process makes it a financially and environmentally sound option compared to subtractive methods.

By understanding its core benefits and trade-offs, you can leverage sintering to move beyond the limitations of traditional manufacturing and create superior components.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Material Properties | Enhanced strength, conductivity, and controlled porosity. |

| Part Complexity | Enables intricate, near-net-shape geometries. |

| Precision & Repeatability | High dimensional accuracy and consistency for volume production. |

| Cost & Sustainability | Minimal material waste reduces cost and environmental impact. |

Ready to leverage sintering for your high-performance components?

KINTEK specializes in providing the advanced lab equipment and consumables necessary for precise sintering processes. Whether you are developing new materials or scaling up production of complex parts, our expertise ensures you achieve the superior strength, intricate geometries, and cost efficiency that sintering offers.

Contact our experts today to discuss how our solutions can enhance your manufacturing capabilities and bring your designs to life.

Visual Guide

Related Products

- Mesh belt controlled atmosphere furnace

- Spark Plasma Sintering Furnace SPS Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

People Also Ask

- Why is a horizontal tube furnace with a H2-N2 atmosphere used for NiO pre-treatment? Key to Catalyst Activation

- Why is a high-precision atmosphere furnace essential for high-nickel cathode sintering? Unlock Battery Performance

- Why Use Ultra-High Vacuum Furnaces for LLZO? Ensure Chemical Stability & Interface Integrity in Solid Electrolytes

- What is the core function of a high-temperature atmosphere sintering furnace in the fabrication of Ni-Al2O3-TiO2 composites?

- Why is precise temperature control in a sintering furnace critical for NASICON electrolytes? Ensure Material Purity