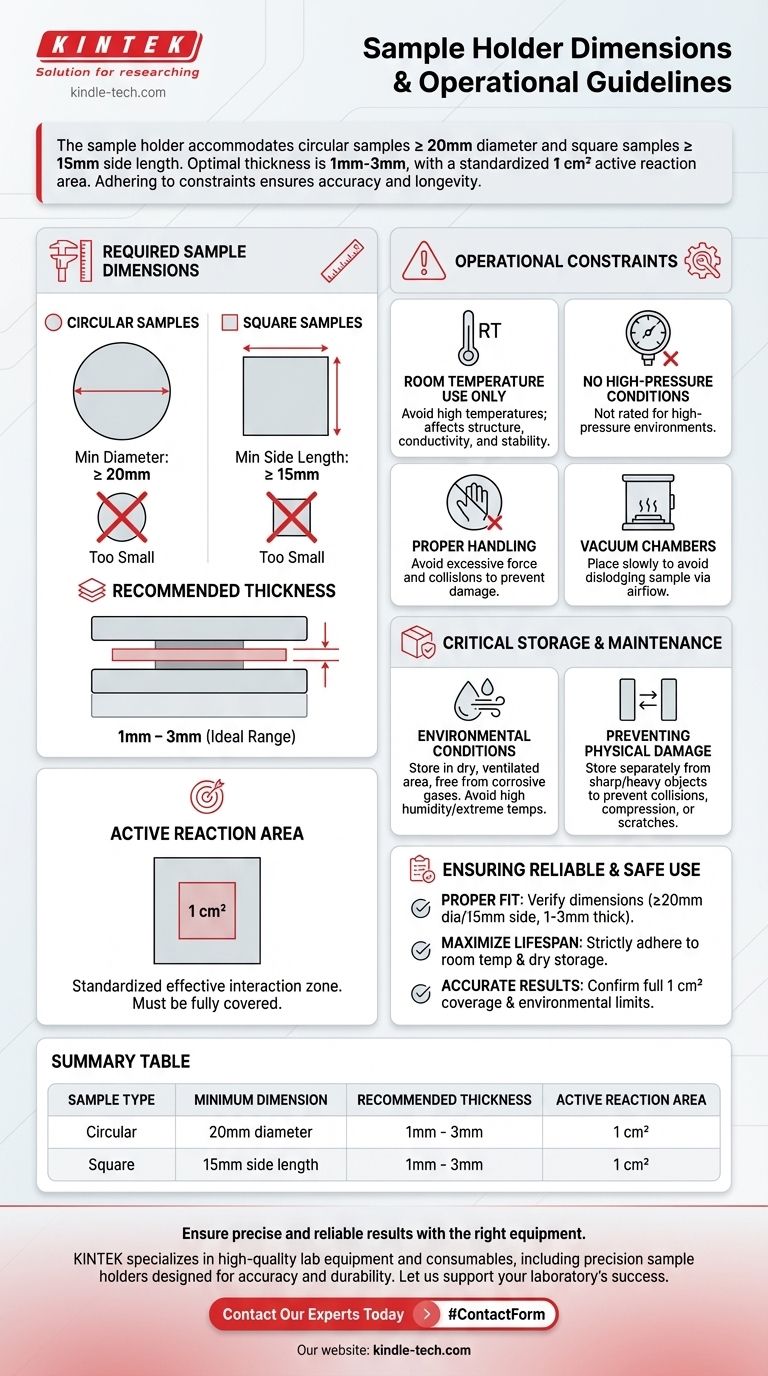

The sample holder accommodates circular samples with a diameter of 20mm or greater and square samples with a side length of 15mm or greater. For optimal performance, the sample thickness should be maintained between 1mm and 3mm. The active reaction area for any sample is a standardized one square centimeter.

Beyond the physical dimensions, the holder's true utility is defined by its operational limits. Adhering to its specific temperature, pressure, and handling constraints is essential for both experimental accuracy and the longevity of the equipment.

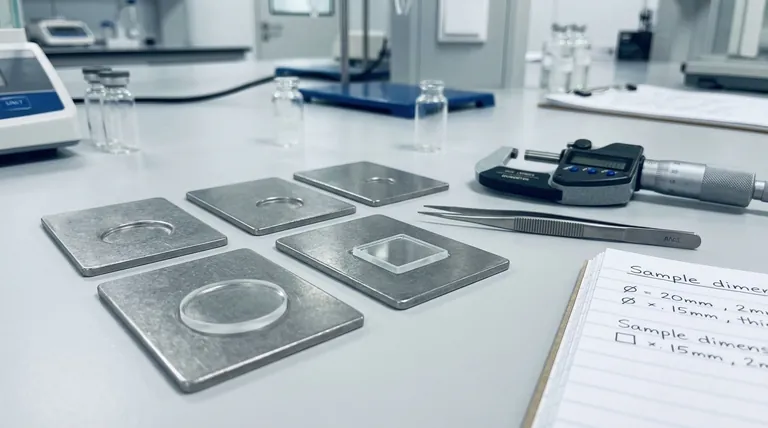

Required Sample Dimensions

To ensure a secure fit and proper function, your sample must conform to a set of minimum dimensions and a specific thickness range.

For Circular Samples

The minimum acceptable diameter for a circular sample is 20mm. Anything smaller will not be adequately secured by the holder.

For Square Samples

For square-shaped samples, the minimum side length required is 15mm.

Recommended Thickness

The ideal sample thickness is between 1mm and 3mm. This range ensures proper contact and stability within the holder's assembly.

The Significance of the Reaction Area

Regardless of the overall sample size, the effective area of interaction is fixed at one square centimeter (1 cm²). It is critical that your material of interest fully covers this designated zone.

Understanding the Operational Constraints

This sample holder is a precision tool designed for specific experimental conditions. Operating outside these boundaries can lead to inaccurate results or damage to the equipment.

Intended for Room Temperature Use

The holder is explicitly designed for use at room temperature. High temperatures can alter its physical structure, which in turn affects its electrical conductivity and chemical stability.

Not for High-Pressure Conditions

Similarly, the holder should not be used in high-pressure environments. Its construction is not rated for such conditions.

Proper Handling Procedures

Always follow the standard operating procedures for your experiment. Avoid applying excessive force or causing collisions, as this can damage both the sample and the holder.

A Note on Vacuum Chambers

When using the holder in a vacuum chamber, it must be placed into the chamber slowly. Rapid movement can create airflow that dislodges the sample from its position.

Critical Storage and Maintenance Guidelines

Proper storage is not optional; it is fundamental to maintaining the holder's integrity and performance over time.

Environmental Conditions

Store the holder in a dry, ventilated environment that is completely free from corrosive gases. Avoid locations with high humidity or extreme temperatures.

Preventing Physical Damage

Whenever possible, store the holder separately from sharp or heavy objects. This prevents damage from accidental collisions, compression, or scratches.

How to Ensure Reliable and Safe Use

Your goal determines how you should prioritize these guidelines.

- If your primary focus is ensuring a proper fit: Verify your sample meets the minimum 20mm diameter or 15mm side length and falls within the 1-3mm thickness range.

- If your primary focus is maximizing holder lifespan: Strictly adhere to the room temperature operating limit and the dry, ventilated storage requirements.

- If your primary focus is achieving accurate results: Confirm your sample fully covers the 1 cm² reaction area and that you are operating within the holder's environmental limits.

Following these specifications ensures your equipment performs reliably and delivers valid, repeatable results.

Summary Table:

| Sample Type | Minimum Dimension | Recommended Thickness | Active Reaction Area |

|---|---|---|---|

| Circular | 20mm diameter | 1mm - 3mm | 1 cm² |

| Square | 15mm side length | 1mm - 3mm | 1 cm² |

Ensure precise and reliable results with the right equipment.

KINTEK specializes in high-quality lab equipment and consumables, including precision sample holders designed for accuracy and durability. Whether you're working with circular or square samples, our products help you maintain experimental integrity and achieve repeatable outcomes.

Let us support your laboratory's success. Contact our experts today to find the perfect sample holder for your specific needs and learn more about our full range of reliable lab solutions.

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the factors that affect melting and boiling point? Unlock the Science of Phase Transitions

- What is the minimum sample required for XRD analysis? Optimize Your Material Analysis

- Why is an airtight sample holder with a beryllium window required for XRD of sulfide solid electrolytes?

- What affects melting point chemistry? A Guide to Molecular Forces and Lattice Energy

- Does higher heat capacity mean higher melting point? Unraveling the Critical Difference