At its core, vacuum freeze-drying is a premier preservation technology with significant applications in bioengineering, pharmaceuticals, the food industry, material science, and laboratory research. Its unique process allows for the removal of water from a product without using high heat, thereby preserving its original structure, chemistry, and biological activity with remarkable fidelity.

The fundamental value of freeze-drying lies in its ability to convert frozen water directly into vapor under a vacuum—a process called sublimation. This avoids the liquid phase, preventing the structural damage and chemical degradation often caused by conventional heat-based dehydration.

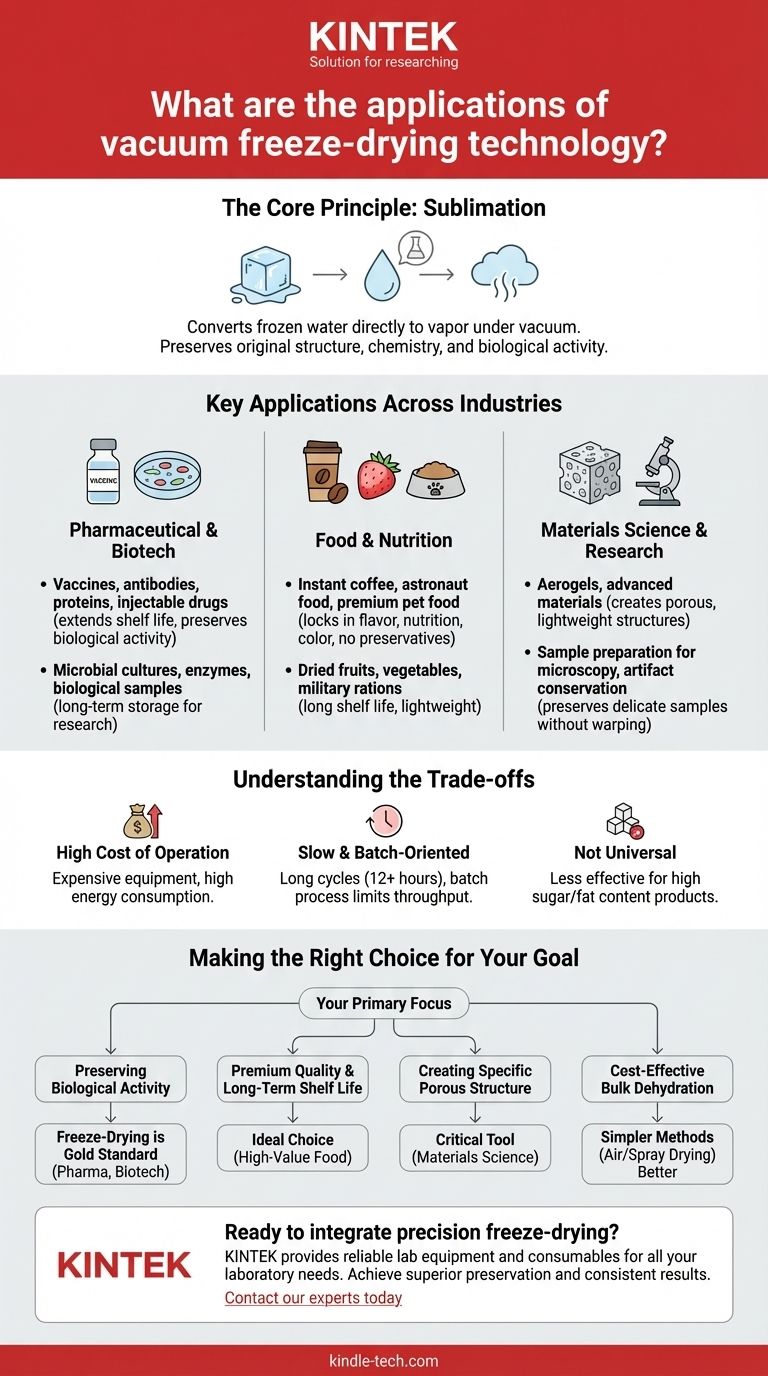

The Core Principle: Why Freeze-Drying is Different

Freeze-drying, or lyophilization, is fundamentally a dehydration process, but its method is what sets it apart. It gently removes water while leaving the product's essential characteristics intact.

Sublimation: The Key to Preservation

The process involves three main stages. First, the material is frozen solid. Next, it is placed under a deep vacuum. This low pressure allows the frozen water (ice) to turn directly into a gas (water vapor) without ever melting, a physical change known as sublimation.

Finally, a secondary drying phase gently warms the product to remove any remaining unfrozen water molecules.

Preserving Delicate Structures

Because the water is removed without passing through a liquid state, the product's original cellular and molecular structure is left behind, creating a porous, lightweight final product. This is crucial for preserving the function of sensitive biological materials and the texture of high-quality foods.

Key Applications Across Industries

The ability to preserve delicate materials makes freeze-drying indispensable in fields where product quality and stability are non-negotiable.

The Pharmaceutical and Biotech Sectors

This is one of the most critical applications. Freeze-drying is used to stabilize and extend the shelf life of vaccines, antibodies, proteins, and other injectable drugs that would otherwise degrade quickly in liquid form.

It is also essential for preserving microbial cultures, enzymes, and biological samples for long-term storage and research, ensuring their viability is maintained for future use.

The Food and Nutrition Industry

In the food industry, freeze-drying creates high-value products with an exceptionally long shelf life without the need for preservatives. The process locks in nutritional value, flavor, and color.

Common examples include astronaut food, instant coffee, military rations, and high-quality dried fruits, vegetables, and even entire meals for backpackers. The pet food industry also uses it to create premium, nutrient-rich raw food.

Advanced Materials and Research

Scientists use freeze-drying to create highly porous, lightweight materials known as aerogels. It is also used in laboratories to prepare samples for analysis with techniques like scanning electron microscopy.

Furthermore, the technology plays a role in conservation, such as preserving waterlogged books or archeological artifacts by gently removing water without causing the material to warp or decay.

Understanding the Trade-offs

While powerful, freeze-drying is not always the optimal choice. It involves significant compromises in cost and efficiency that must be considered.

High Cost of Operation

Freeze-drying equipment is expensive to purchase, operate, and maintain. The deep vacuum and low temperatures required consume a significant amount of energy, making it one of the most costly dehydration methods.

Slow and Batch-Oriented Process

Freeze-drying cycles are notoriously long, often taking anywhere from 12 hours to several days to complete. It is a batch process, not a continuous one, which limits throughput compared to methods like spray drying or air drying.

Not a Universal Solution

The process is less effective for products with very high sugar or fat content, as these can interfere with the formation of a proper frozen structure, leading to product collapse and poor results without specialized formulation.

Making the Right Choice for Your Goal

Selecting freeze-drying depends entirely on whether its unique benefits justify the significant costs and time investment.

- If your primary focus is preserving biological activity: Freeze-drying is the gold standard for stabilizing sensitive pharmaceuticals, vaccines, and lab specimens.

- If your primary focus is premium quality and long-term shelf life: It is the ideal choice for high-value food products where taste, nutrition, and texture are paramount.

- If your primary focus is creating a specific porous structure: It is a critical tool in materials science for developing advanced materials like aerogels.

- If your primary focus is cost-effective bulk dehydration: Simpler methods like air drying or spray drying are almost always a more practical choice.

Ultimately, freeze-drying is a precision tool for applications where preserving the original integrity of the material is more important than anything else.

Summary Table:

| Application Area | Key Use Cases | Primary Benefit |

|---|---|---|

| Pharmaceutical & Biotech | Vaccines, proteins, injectable drugs, microbial cultures | Preserves biological activity and extends shelf life |

| Food & Nutrition | Instant coffee, astronaut food, premium pet food, dried fruits | Locks in flavor, nutrition, and color without preservatives |

| Materials Science & Research | Aerogels, sample preparation for microscopy, artifact conservation | Creates porous structures and preserves delicate samples |

Ready to integrate precision freeze-drying into your workflow? KINTEK specializes in providing reliable lab equipment and consumables for all your laboratory needs. Whether you are developing next-generation pharmaceuticals, creating premium food products, or conducting advanced materials research, our solutions help you achieve superior preservation and consistent results. Contact our experts today to find the perfect freeze-drying solution for your specific application!

Visual Guide

Related Products

- Benchtop Laboratory Vacuum Freeze Dryer

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- How does the use of a vacuum freeze dryer benefit cys-CDs powder preparation? Preserve Nanoparticle Integrity

- What are the advantages of using freeze drying for phase change materials with biopolymer shells? Optimize Stability

- What is the function of Freeze-thaw Equipment in Au-(PNiPAAm/PVA) hydrogel? Achieve High-Speed Photothermal Actuation

- What is the application of freeze dryers in the preparation of enzyme catalysts? Preserve Bioactivity and Porosity

- How does liquid nitrogen provide physical protection for heat-sensitive drugs? Ensure Superior Biological Integrity