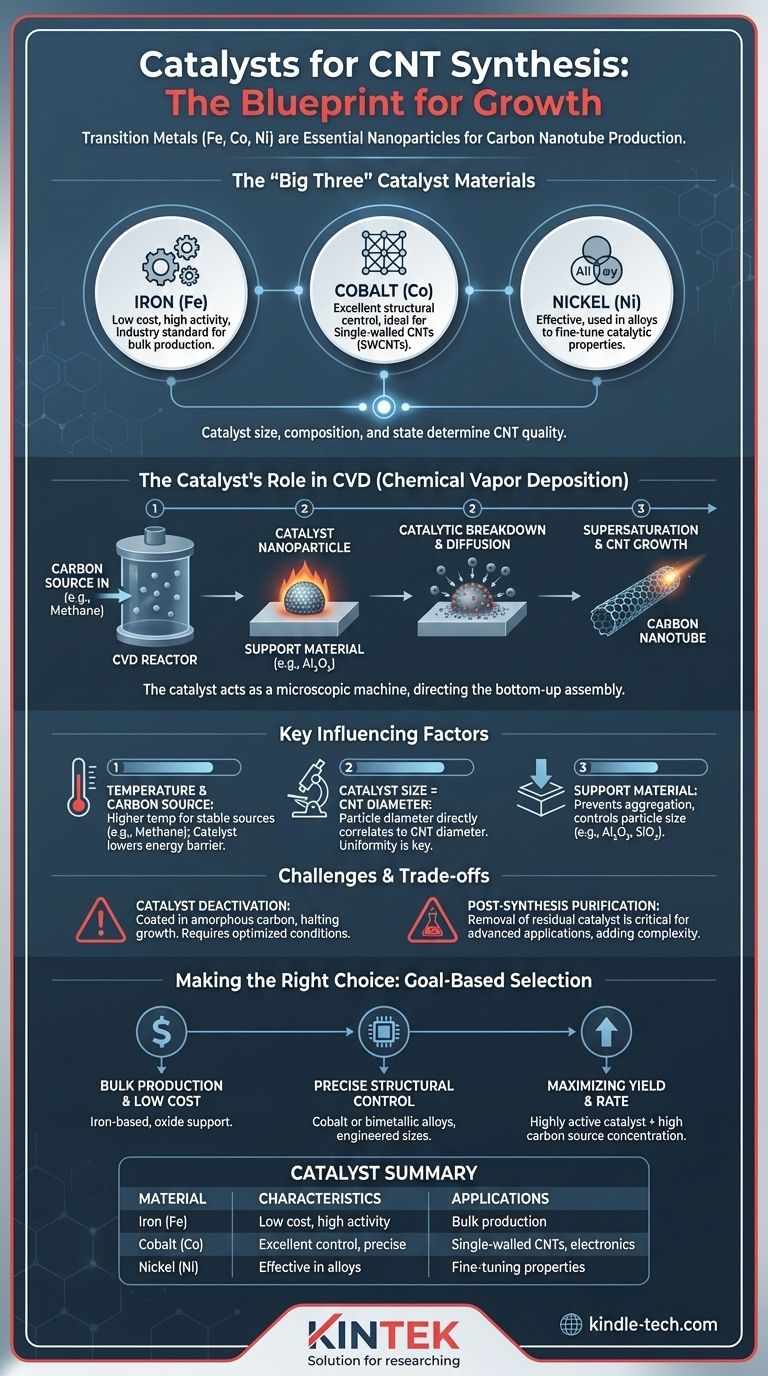

In short, the most common and effective catalysts for carbon nanotube (CNT) synthesis are nanoparticles of transition metals, specifically iron (Fe), cobalt (Co), and nickel (Ni). These metals, or their alloys, are essential for decomposing the carbon source and templating the growth of the nanotube structure in widely used methods like Chemical Vapor Deposition (CVD).

The catalyst is not merely an ingredient; it is the foundational seed for CNT growth. Its size, composition, and state directly determine the diameter, structure, and quality of the resulting carbon nanotubes, making catalyst selection the most critical decision in the synthesis process.

The Catalyst's Role in Building a Nanotube

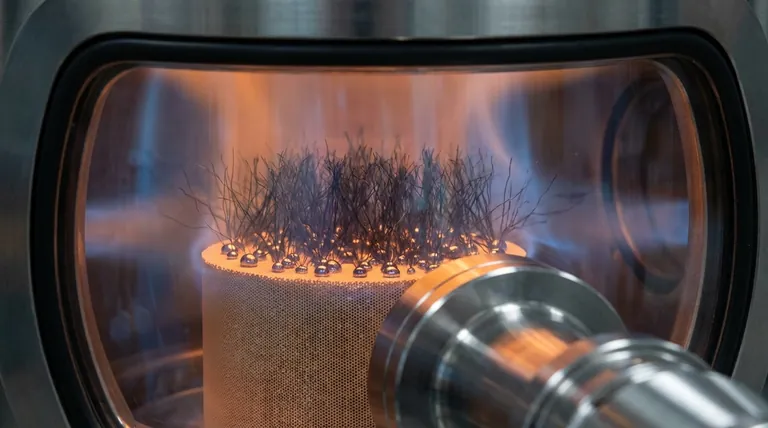

The synthesis of CNTs is a bottom-up construction process, and the catalyst particle is the microscopic machine that directs the assembly. This is particularly true for Chemical Vapor Deposition (CVD), the dominant commercial production method.

The Growth Mechanism Explained

In a typical CVD process, a carbon-containing gas, such as methane or ethylene, is introduced into a high-temperature reactor.

The catalyst nanoparticle, heated to a high temperature, performs two critical functions. First, it catalytically breaks down the carbon source gas on its surface.

Second, the carbon atoms dissolve into and diffuse through the metal particle. Upon reaching supersaturation, the carbon precipitates out in a stable, graphitic form, creating the cylindrical wall of the nanotube.

The "Big Three" Catalyst Materials

While many metals have been explored, the field consistently relies on a select few due to their unique properties.

Iron (Fe) is the most widely used catalyst due to its low cost, high catalytic activity, and effectiveness across a range of conditions.

Cobalt (Co) is highly effective and often used when precise control over the CNT structure, such as producing single-walled nanotubes, is the primary goal.

Nickel (Ni) is another effective catalyst, sometimes used in alloys with the other metals to fine-tune catalytic properties for specific applications.

The Importance of the Support

The catalyst particles are rarely used alone. They are typically deposited onto a stable, high-surface-area support material, such as alumina (Al₂O₃) or silica (SiO₂).

The support prevents the catalyst nanoparticles from clumping together (aggregating) at high temperatures. This ensures a high density of active sites for CNT growth and provides a method for controlling the initial size of the catalyst particles.

How Process Conditions Affect the Catalyst

The operating parameters mentioned in synthesis—temperature, carbon source, and time—do not exist in a vacuum. They are all dialed in relative to the chosen catalyst system.

Temperature and Carbon Source

A more stable carbon source like methane requires more energy (higher temperatures) to decompose compared to less stable sources like acetylene.

The catalyst's role is to lower this energy barrier. A highly active catalyst can enable the use of lower temperatures or more stable feedstocks, improving energy efficiency.

Catalyst Size Dictates CNT Diameter

One of the most fundamental principles in CNT synthesis is that the diameter of the catalyst nanoparticle directly correlates to the diameter of the CNT that grows from it.

Achieving a uniform batch of CNTs requires creating a uniform population of catalyst particles on the support material beforehand. This control is a major focus of catalyst research.

Common Pitfalls and Trade-offs

While essential, catalysts also introduce significant challenges that must be managed to produce high-quality material.

Catalyst Deactivation

During synthesis, the catalyst particle can become coated in amorphous carbon or other byproducts, rendering it inactive and halting CNT growth.

Optimizing gas flow rates, concentrations, and temperature is crucial to keep the catalyst active for as long as possible, maximizing yield.

Post-Synthesis Purification

For most advanced applications, such as in electronics or batteries, the presence of residual metal catalyst is a critical impurity that degrades performance.

Therefore, a significant post-processing step involving aggressive acid washing is often required to remove the catalyst, adding complexity and cost to the overall process.

Making the Right Choice for Your Goal

The ideal catalyst is entirely dependent on the desired outcome, balancing cost, yield, and the specific properties of the final CNT product.

- If your primary focus is bulk production at the lowest cost: Iron-based catalysts on a simple oxide support are the industry standard.

- If your primary focus is precise structural control (e.g., for semiconductors): Cobalt or bimetallic alloys with carefully engineered particle sizes are the preferred choice.

- If your primary focus is maximizing yield and growth rate: A highly active catalyst system must be balanced with high concentrations of carbon sources, managing the trade-off of increased energy consumption.

Ultimately, understanding that the catalyst particle acts as the blueprint for the nanotube is the key to controlling the synthesis process.

Summary Table:

| Catalyst Material | Key Characteristics | Common Applications |

|---|---|---|

| Iron (Fe) | Low cost, high activity, industry standard | Bulk production, general-purpose CNTs |

| Cobalt (Co) | Excellent structural control, precise | Single-walled CNTs, electronics, semiconductors |

| Nickel (Ni) | Effective catalyst, often used in alloys | Fine-tuning properties for specific needs |

Ready to optimize your CNT synthesis process? The right catalyst system is the blueprint for success. At KINTEK, we specialize in providing the high-purity lab equipment and consumables—including catalyst materials and CVD systems—that researchers and manufacturers need to achieve precise control over carbon nanotube growth. Let our expertise support your innovation in materials science. Contact our team today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Warm Isostatic Press for Solid State Battery Research

People Also Ask

- What are the temperature and pressure limitations for using the sample holder? Essential Guide for Lab Safety

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination

- What is the correct way to place items into a PTFE cleaning basket? Master the Art of Perfect, Repeatable Cleaning

- What are the recommended and prohibited cleaning methods for the PTFE electrode stand? Protect Your Lab Equipment

- What are the storage requirements for the PTFE electrode stand after cleaning? Preserve Purity and Equipment Longevity