At its core, heat treatment is a highly controlled process of heating and cooling metals to intentionally alter their internal crystalline structure. The primary categories are not just a list of techniques but are best understood by their intended outcome: making a metal softer and more workable (annealing), making it harder and more wear-resistant (hardening), or refining its properties for a specific purpose (tempering). Processes like quenching are not a category but a critical step within the hardening process.

Heat treatment is fundamentally about manipulating a metal's microstructure. By carefully managing temperature and time, you can precisely dial in physical properties like hardness, toughness, and ductility to meet a specific engineering requirement.

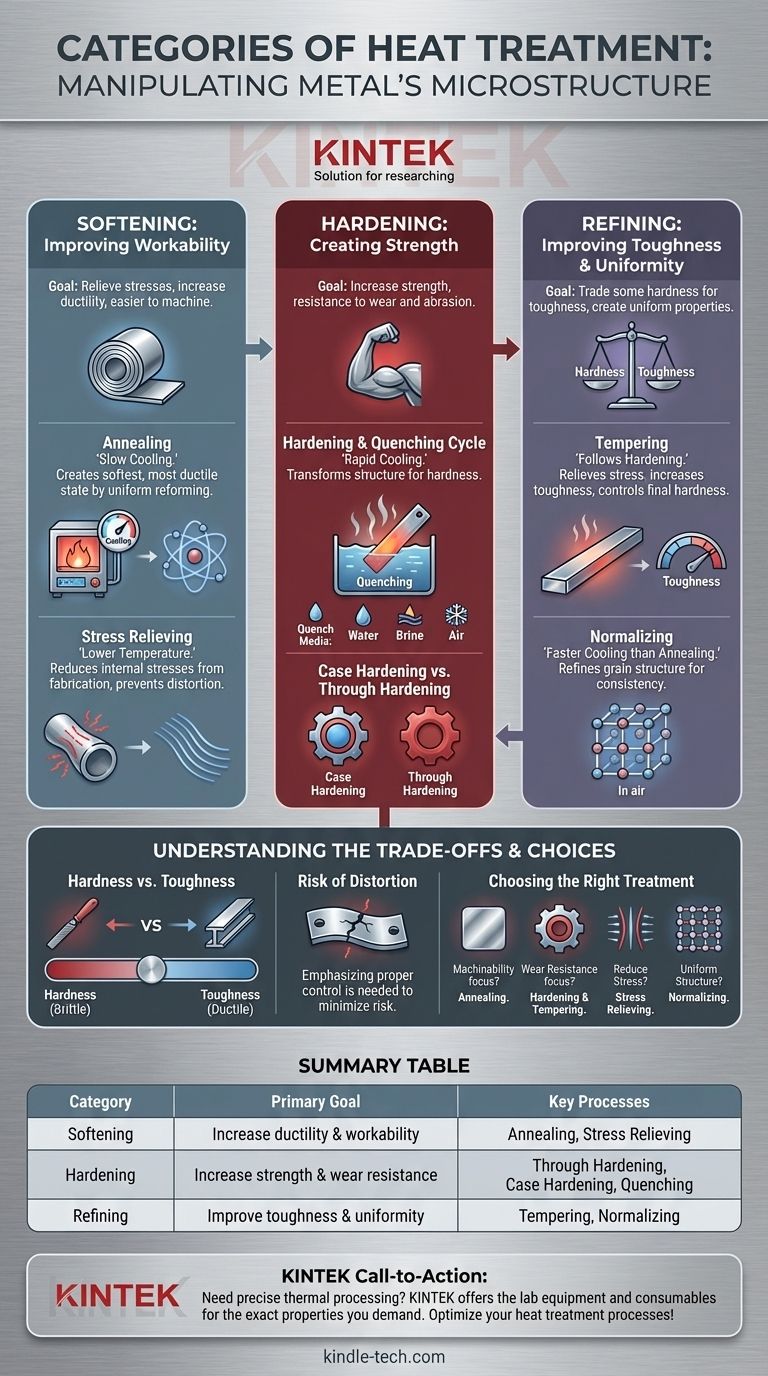

The Goal of Softening: Improving Workability

The primary objective of softening treatments is to relieve stresses, increase ductility, and make the material easier to machine or form.

What is Annealing?

Annealing produces a metal in its softest, most ductile state. The process involves heating the material to a specific temperature, holding it there, and then cooling it very slowly, often by leaving it in the furnace to cool.

This slow cooling allows the metal's internal grain structure to reform into a uniform, stress-free state, maximizing its softness and machinability.

The Purpose of Stress Relieving

Stress relieving is a lower-temperature process used to reduce internal stresses that have built up during manufacturing processes like welding, machining, or cold forming.

These stresses can lead to distortion or cracking over time. Stress relieving heats the part enough to relax these stresses without significantly changing its overall hardness or mechanical properties.

The Goal of Hardening: Creating Strength

Hardening processes are designed to increase a material's strength and its resistance to wear and abrasion. This is achieved by creating a very hard microstructure.

The Hardening and Quenching Cycle

Hardening involves heating a metal (typically steel) to a high temperature to transform its crystal structure and then cooling it with extreme speed.

This rapid cooling, known as quenching, is what "freezes" the hard structure in place. Quenching is not a category of heat treatment itself, but the critical cooling step that enables hardening.

Different quench media (water, oil, brine, or forced air) provide different cooling rates, which are chosen based on the type of steel and the part's geometry to avoid cracking.

Case Hardening vs. Through Hardening

Through hardening aims to achieve a consistent hardness throughout the entire cross-section of a part.

Case hardening, by contrast, creates a very hard, wear-resistant outer layer (the "case") while leaving the interior core tough and ductile. This is ideal for parts like gears that need a durable surface but must also resist shock and impact without shattering.

Refining Properties After Hardening

A fully hardened part is often too brittle for practical use. Subsequent treatments are used to refine its properties, trading some hardness for a crucial increase in toughness.

Why Tempering Follows Hardening

Tempering is a secondary, lower-temperature heat treatment performed immediately after a part has been hardened and quenched.

It slightly reduces the extreme hardness but, more importantly, it relieves internal stresses and significantly increases the material's toughness, which is its ability to absorb energy and resist fracturing. The final hardness is controlled by the tempering temperature.

Normalizing for a Uniform Structure

Normalizing is similar to annealing but uses a faster cooling rate, typically by letting the part cool in still air.

This process refines the grain structure, making it more uniform. The result is a metal that is stronger and harder than an annealed part but less brittle than a fully hardened one, providing a predictable and consistent material for subsequent machining or heat treatment.

Understanding the Trade-offs

Choosing a heat treatment is always an exercise in balancing competing properties. There is no single "best" process, only the most appropriate one for the application.

The Hardness vs. Toughness Dilemma

This is the most fundamental trade-off in heat treatment. As you increase a material's hardness, you almost always decrease its toughness and ductility, making it more brittle.

A file needs to be extremely hard to cut other metals, so it is made brittle. A structural steel beam for a building needs to be tough to resist fracture, so its hardness is much lower.

The Risk of Distortion and Cracking

The rapid temperature changes involved in heat treatment, especially quenching, induce significant internal stress. If not managed correctly, this can cause parts to warp, distort, or even crack during the process.

Proper process control, material selection, and part design are critical to minimizing these risks.

Choosing the Right Treatment for Your Goal

Your choice must be driven by the final performance requirements of the component.

- If your primary focus is maximum machinability and formability: Annealing is your go-to process to make the metal as soft and ductile as possible.

- If your primary focus is high wear resistance and strength: A hardening process (like through hardening or case hardening) followed by tempering is the correct path.

- If your primary focus is reducing stress from fabrication to prevent future warping: Stress relieving is the targeted solution that won't significantly alter the material's core properties.

- If your primary focus is creating a uniform and refined microstructure for predictable performance: Normalizing provides a consistent baseline for either final use or a subsequent hardening cycle.

Ultimately, selecting the correct heat treatment requires a clear understanding of the final properties your component needs to achieve.

Summary Table:

| Category | Primary Goal | Key Processes |

|---|---|---|

| Softening | Increase ductility & workability | Annealing, Stress Relieving |

| Hardening | Increase strength & wear resistance | Through Hardening, Case Hardening, Quenching |

| Refining | Improve toughness & uniformity | Tempering, Normalizing |

Need to specify the perfect heat treatment for your materials? KINTEK specializes in the lab equipment and consumables necessary for precise thermal processing. Our expertise ensures you achieve the exact hardness, toughness, and durability your project demands. Contact our experts today to optimize your heat treatment processes!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Why is sintering important in ceramic processing? Achieve Dense, High-Performance Ceramic Parts

- What is a muffle furnace? The Definitive Tool for Contaminant-Free, Precise Heating

- What is a muffle furnace for laboratory use? A Guide to Contaminant-Free High-Temperature Processing

- What is the working principle of muffle furnace? Achieving Pure, Uniform High-Temperature Processing

- Why is it called a muffle furnace? The Key to Contamination-Free High-Temperature Heating