Despite their growing popularity, lab-grown diamonds face significant challenges that are critical for any potential buyer or user to understand. The primary obstacles are not related to their physical quality but to their economic and cultural standing. These include rapidly changing prices that make them unsuitable for investment, a perceived loss of uniqueness compared to natural stones, and specific technical limitations in non-jewelry applications.

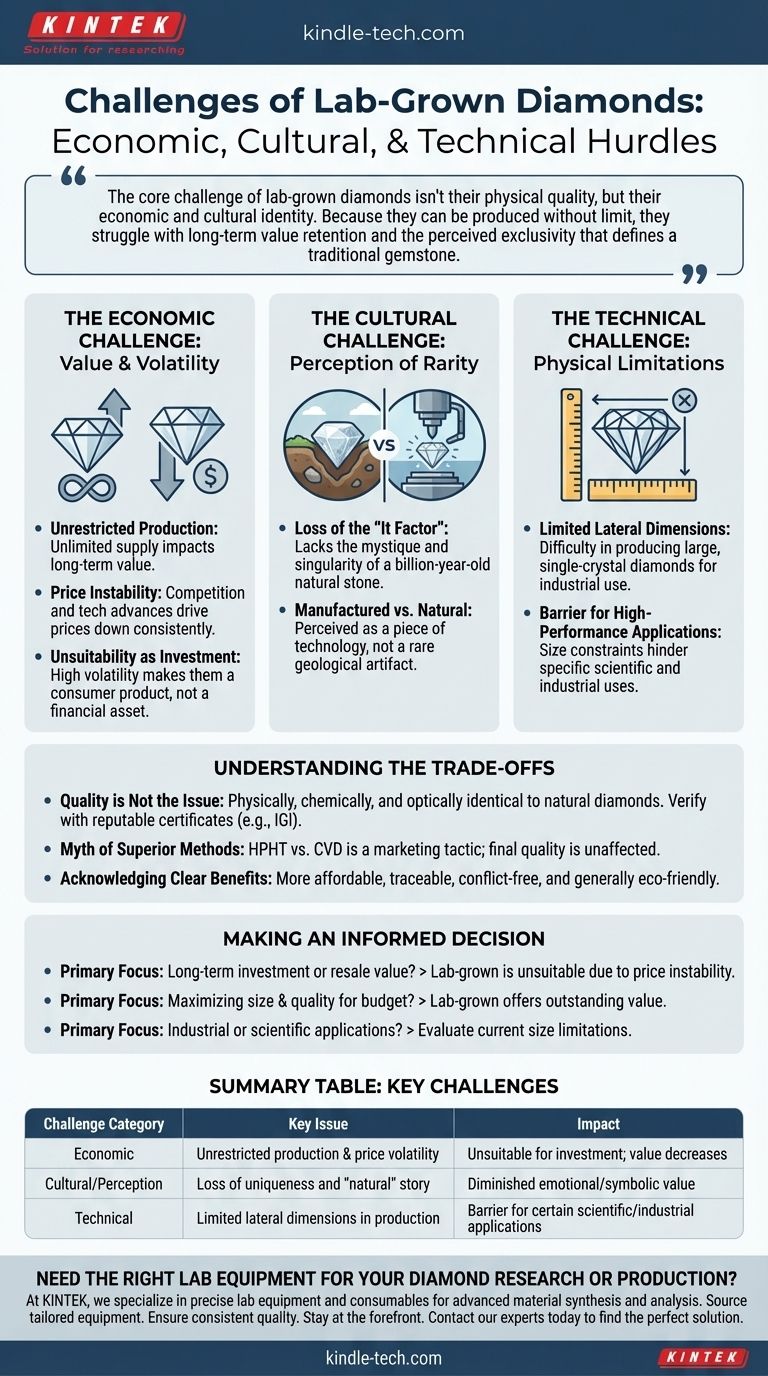

The core challenge of lab-grown diamonds isn't their physical quality, but their economic and cultural identity. Because they can be produced without limit, they struggle with long-term value retention and the perceived exclusivity that defines a traditional gemstone.

The Economic Challenge: Value and Volatility

The most significant challenge for lab-grown diamonds is their economic model, which is fundamentally different from that of natural diamonds.

Unrestricted Production

Unlike natural diamonds, which are a finite resource, lab-grown diamonds can be manufactured in potentially unlimited quantities. This reality of unrestricted supply directly impacts their long-term value.

Price Instability

The market for lab-grown diamonds is characterized by increasing competition and rapid technological advancements in production methods like HPHT and CVD. These factors consistently drive prices down, making their value highly volatile.

Unsuitability as an Investment

Due to this price volatility and the potential for future cost reductions, lab-grown diamonds are not considered a stable store of value. They are a consumer product, not a long-term financial asset.

The Cultural Challenge: Perception of Rarity

For centuries, the allure of a diamond has been tied to its story as a unique, one-of-a-kind treasure from the earth. Lab-grown diamonds challenge this perception.

The Loss of the "It Factor"

Lab-grown diamonds, being manufactured products, can lack the sense of mystique and singularity associated with a gem formed over billions of years. This perception can diminish their emotional or symbolic value for some consumers.

Manufactured Goods vs. Natural Artifacts

The process of creating a diamond in a lab, while technologically impressive, frames it as a piece of technology rather than a rare geological artifact. This distinction is central to the debate over their intrinsic value and allure.

The Technical Challenge: Physical Limitations

Beyond the consumer market, lab-grown diamonds face hurdles in certain high-performance applications.

Limited Lateral Dimensions

A key manufacturing constraint is the difficulty in producing diamonds with large lateral dimensions. This size limitation can be a substantial barrier for specific scientific or industrial uses that require larger single-crystal diamonds.

Understanding the Trade-offs

A balanced view requires acknowledging where these challenges do and do not apply. It's crucial to separate market myths from facts.

Quality is Not the Issue

It is essential to know that lab-grown diamonds are physically, chemically, and optically identical to natural ones. The challenges discussed here are not about inferiority but about origin and supply. Always verify quality with a reputable certificate, such as one from the IGI.

The Myth of Superior Methods

Claims that one production method (HPHT vs. CVD) is superior to the other are unfounded marketing tactics. The synthesis method does not affect the final quality, beauty, or price of the diamond.

Acknowledging the Clear Benefits

The challenges of value retention are balanced by clear advantages. Lab-grown diamonds are more affordable, have a fully traceable and conflict-free origin, and are generally more environmentally friendly than mined diamonds.

Making an Informed Decision

Your choice should be guided by a clear understanding of your primary goal.

- If your primary focus is long-term investment or resale value: The price instability of lab-grown diamonds makes them an unsuitable choice for this purpose.

- If your primary focus is maximizing size and quality for your budget: Lab-grown diamonds offer outstanding value, allowing you to acquire a larger or higher-quality stone for a lower cost.

- If your primary focus is on industrial or scientific applications: You must carefully evaluate whether the current size limitations of lab-grown diamonds meet your specific technical requirements.

Ultimately, understanding these challenges empowers you to choose a diamond based on your actual priorities rather than market perceptions.

Summary Table:

| Challenge Category | Key Issue | Impact |

|---|---|---|

| Economic | Unrestricted production & price volatility | Unsuitable for investment; value decreases over time |

| Cultural/Perception | Loss of uniqueness and "natural" story | Diminished emotional/symbolic value for some buyers |

| Technical | Limited lateral dimensions in production | Barrier for certain scientific/industrial applications |

Need the Right Lab Equipment for Your Diamond Research or Production?

Navigating the complexities of lab-grown materials requires reliable, high-performance equipment. At KINTEK, we specialize in providing the precise lab equipment and consumables needed for advanced material synthesis and analysis, including applications involving diamonds.

We help you:

- Source equipment tailored to your specific R&D or production goals.

- Ensure consistent quality and reliable results in your lab.

- Stay at the forefront of material science technology.

Let's discuss your lab's needs. Contact our experts today to find the perfect solution for your challenges.

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond for Thermal Management Applications

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is a microwave plasma reactor? Unlock Precision Synthesis of High-Performance Materials

- What are the applications of microwave plasma? From Diamond Synthesis to Semiconductor Fabrication

- How does microwave plasma work? Unlock Precision Material Synthesis for Advanced Manufacturing

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- Which lab grown diamond process is best? Focus on Quality, Not the Method