At its core, an induction furnace is a highly efficient and clean melting system that uses electromagnetic principles instead of combustion. Its key characteristics include precise temperature control, low environmental impact, and the ability to generate heat directly within the metal being melted. The system consists of a power supply, a control unit, and a water-cooled copper coil that surrounds a crucible containing the charge material.

An induction furnace's primary advantage is its ability to melt materials with exceptional purity and compositional accuracy. By using electricity to induce heat directly within the metal, it eliminates contamination from fuel or electrodes and provides a natural stirring action for a perfectly homogenous final product.

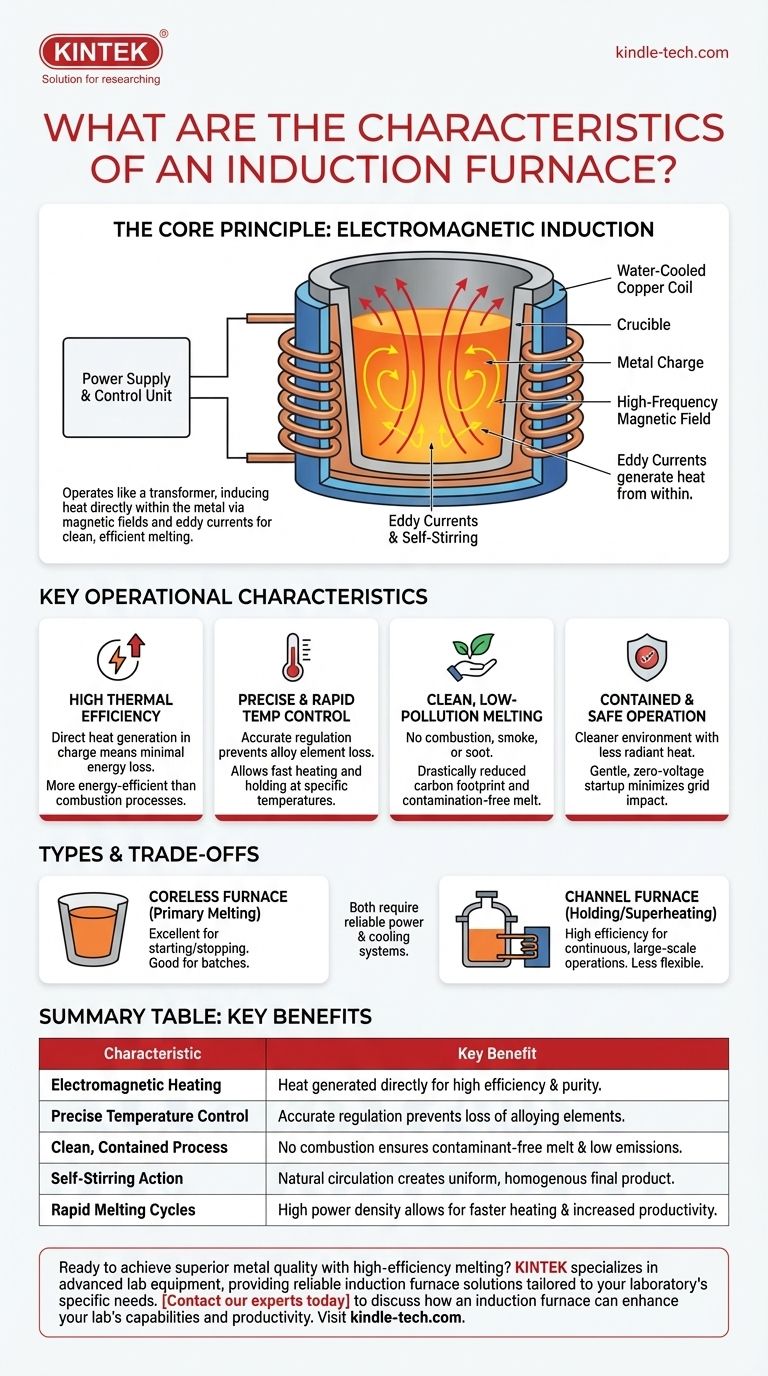

How an Induction Furnace Works: The Core Principle

The technology behind an induction furnace is fundamentally different from traditional fuel-fired or arc furnaces. It relies on a clean, contained, and highly controllable physical phenomenon.

The Power of Electromagnetic Induction

An induction furnace operates like a transformer. A high-frequency alternating current (AC) is passed through a copper coil, creating a powerful and rapidly changing magnetic field around the crucible.

When conductive material like metal is placed within this field, the magnetic field induces circular electrical currents within the metal itself. These are known as eddy currents.

The metal's natural resistance to the flow of these eddy currents generates immense heat, causing the material to melt from the inside out.

Key System Components

A complete induction furnace system is more than just the melting box. Its key parts include:

- Inductor Coil: A water-cooled copper coil that generates the magnetic field.

- Crucible: A refractory container that holds the metal charge inside the coil.

- Power Supply: Converts mains electricity into the high-frequency AC needed for the coil.

- Control System: Allows operators to precisely regulate power, frequency, and temperature.

- Cooling System: A chiller that circulates water through the coil to prevent it from overheating.

The Self-Stirring Effect

The intense magnetic field also creates a force that causes the molten metal to circulate vigorously. This inherent stirring action is a major advantage, ensuring the melt achieves a uniform temperature and a homogenous chemical composition without mechanical stirrers.

Key Operational Characteristics

The unique working principle of an induction furnace gives it several distinct operational advantages that make it the preferred choice for many modern foundries and metallurgical applications.

High Thermal Efficiency

Because heat is generated directly within the charge material, very little energy is lost to the environment. This makes induction melting significantly more energy-efficient than processes that must first heat a chamber and then transfer that heat to the metal.

Precise and Rapid Temperature Control

Operators can regulate melting heat with extreme precision by simply adjusting the power output. This allows for rapid heating and the ability to hold a specific temperature, which is critical for preventing the loss of valuable alloying elements that can burn off at excessive temperatures.

Clean, Low-Pollution Melting

The process involves no combustion, meaning there are no byproducts like smoke, soot, or carbon dioxide. This results in a cleaner final product free from contamination and a drastically reduced carbon footprint for the facility.

Contained and Safe Operation

The melting process is fully contained within the crucible, leading to a cleaner and safer work environment with less radiant heat and mess compared to other furnace types. Modern units feature a gentle, zero-voltage startup, minimizing impact on the facility's electrical grid.

Understanding the Trade-offs and Variations

While highly effective, induction furnaces are not a universal solution. Understanding their different types and requirements is crucial for proper application.

Coreless vs. Channel Furnaces

The most common type is the coreless induction furnace, which uses a simple crucible surrounded by the coil. It is excellent for primary melting and can be started and stopped easily.

A channel induction furnace is designed differently, with a smaller induction unit connected to a main vessel. It functions more like a holding or superheating unit, keeping large volumes of metal molten and at temperature. This type is less flexible but highly efficient for continuous, large-scale operations.

Reliance on Support Systems

The furnace's efficiency depends on a sophisticated ecosystem of support equipment. A reliable, high-capacity power supply and a robust water-cooling system (chiller) are non-negotiable requirements. Failure in either of these ancillary systems will shut down the entire operation.

Initial Investment and Refractory Care

The initial capital cost for an induction furnace system, including the power electronics, can be higher than for simpler furnace types. Additionally, the crucible (refractory lining) is a consumable item that requires careful monitoring and periodic replacement.

Making the Right Choice for Your Application

Selecting an induction furnace depends entirely on your operational priorities.

- If your primary focus is alloy quality and purity: An induction furnace is the ideal choice, as its contamination-free process and self-stirring action ensure a clean, homogenous melt.

- If your primary focus is operational efficiency: This furnace offers superior energy efficiency, rapid heating cycles, and the potential for 24-hour continuous operation.

- If your primary focus is environmental compliance: The absence of combustion and emissions makes it a superior technology for meeting stringent environmental regulations and reducing your carbon footprint.

Ultimately, the induction furnace represents a modern, precise, and highly controlled method for melting metal, empowering industries to produce higher quality materials more efficiently and cleanly.

Summary Table:

| Characteristic | Key Benefit |

|---|---|

| Electromagnetic Heating | Heat generated directly within the metal for high efficiency and purity. |

| Precise Temperature Control | Accurate regulation prevents loss of alloying elements. |

| Clean, Contained Process | No combustion ensures a contaminant-free melt and low emissions. |

| Self-Stirring Action | Natural circulation creates a uniform, homogenous final product. |

| Rapid Melting Cycles | High power density allows for faster heating and increased productivity. |

Ready to achieve superior metal quality with high-efficiency melting?

KINTEK specializes in advanced lab equipment and consumables, providing reliable induction furnace solutions tailored to your laboratory's specific needs. Our expertise ensures you get the precise temperature control, energy efficiency, and contamination-free results your research demands.

Contact our experts today to discuss how an induction furnace can enhance your lab's capabilities and productivity.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What metals can be melted in an induction furnace? A Guide to Efficient Melting for Any Conductive Metal

- What are the types of induction melting furnace? Coreless, Channel, and VIM Explained

- What are the materials for acid lining and basic lining in electric induction furnace? Choose the Right Refractory for Your Melt

- What is the difference between induction furnace and electric furnace? Uncover the Best Heating Method for Your Lab

- Which furnace is most commonly used for melting non ferrous metals? Induction Furnaces for Purity & Efficiency

- What are the advantages of CCIM for titanium deoxygenation? Achieve Ultra-High Purity in Reactive Metal Melting

- What is the raw material of induction furnace? Metal, Refractory Lining, and More

- How to calculate power consumption in an induction furnace? Accurately Estimate Your Energy Needs