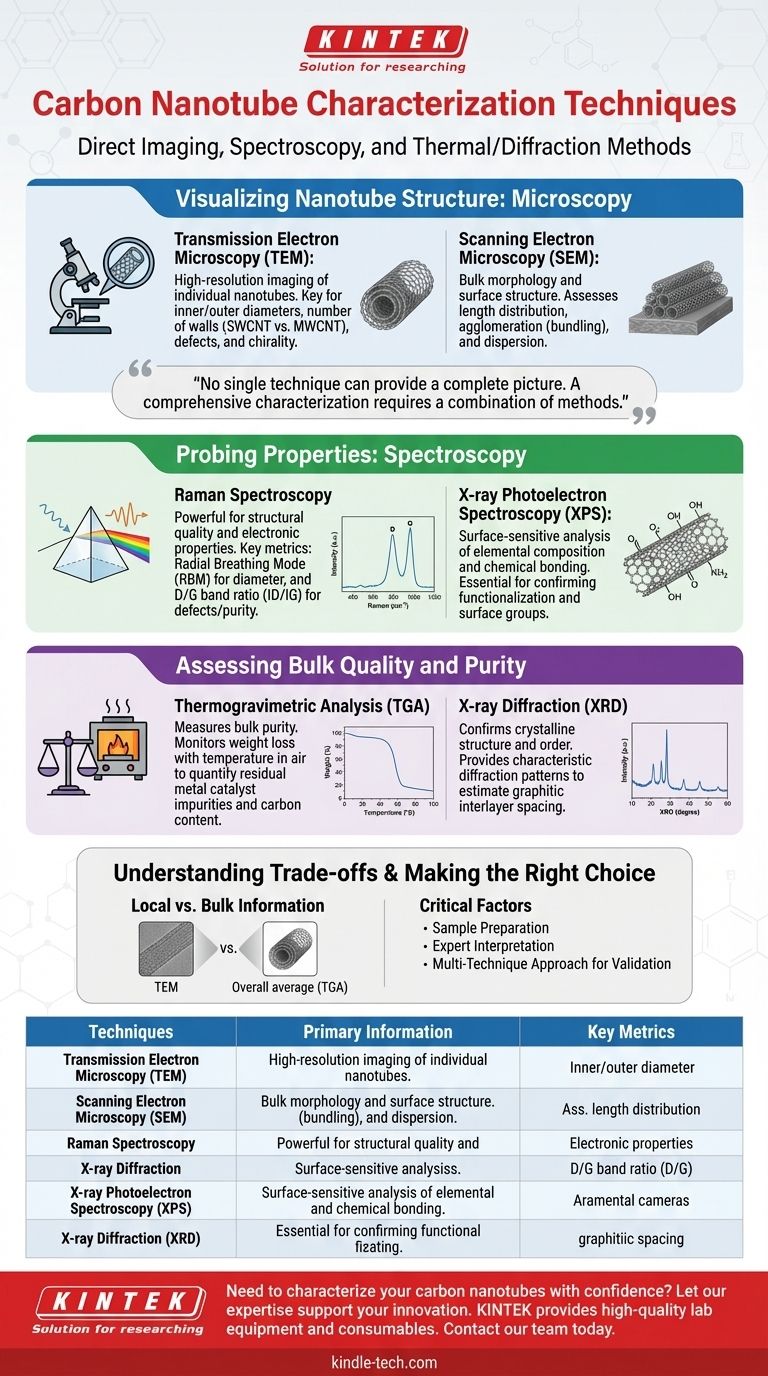

The primary techniques for characterizing carbon nanotubes fall into three main categories: microscopy for direct imaging, spectroscopy for analyzing structural and electronic properties, and thermal or diffraction methods for assessing bulk purity and crystalline order. Techniques like Transmission Electron Microscopy (TEM), Raman Spectroscopy, and Thermogravimetric Analysis (TGA) are fundamental tools used to verify the quality, structure, and purity of a CNT sample.

No single technique can provide a complete picture of a carbon nanotube sample. A comprehensive characterization requires a combination of methods to correlate the visual structure with the material's underlying physical and chemical properties.

Visualizing Nanotube Structure: Microscopy

To understand the physical form of the nanotubes you have produced or acquired, direct imaging is the most intuitive starting point. Electron microscopy provides the necessary magnification to resolve nanoscale features.

Transmission Electron Microscopy (TEM)

TEM is the gold standard for high-resolution imaging of individual nanotubes. It works by passing a beam of electrons through an ultra-thin sample.

This technique directly reveals the most fundamental structural details: the inner and outer diameters, the number of walls (distinguishing between single-walled and multi-walled CNTs), and the presence of structural defects or encapsulated catalyst particles. In some cases, high-resolution TEM can even help determine the nanotube's chirality.

Scanning Electron Microscopy (SEM)

SEM provides lower-magnification images of the sample's surface by scanning it with a focused electron beam. It does not show the internal structure of individual tubes.

Its primary value is in assessing the bulk morphology of the CNT sample. SEM is excellent for visualizing the length distribution, degree of agglomeration (bundling), and the overall dispersion of nanotubes within a composite matrix.

Probing Properties: Spectroscopy

Spectroscopic techniques analyze how the nanotubes interact with different forms of energy (like light) to provide detailed information about their quality, electronic nature, and chemical state.

Raman Spectroscopy

Raman Spectroscopy is arguably the most powerful and widely used technique for CNT characterization. It is non-destructive and provides a wealth of information from a single measurement.

Key features in the Raman spectrum identify the Radial Breathing Mode (RBM), whose position is inversely proportional to the nanotube diameter, and the D-band and G-band. The ratio of the D-band to G-band (ID/IG) is a critical metric for quantifying the level of defects or amorphous carbon in the sample.

X-ray Photoelectron Spectroscopy (XPS)

XPS is a surface-sensitive technique used to determine the elemental composition and chemical bonding states on the surface of the nanotubes.

This is particularly crucial when nanotubes have been intentionally functionalized—for example, by adding oxygen or nitrogen groups to their surface. XPS confirms the success of these chemical modifications.

Assessing Bulk Quality and Purity

While microscopy and spectroscopy analyze small, localized areas, other techniques are needed to understand the properties of the entire bulk sample.

Thermogravimetric Analysis (TGA)

TGA is the primary method for measuring the purity of a CNT sample. The sample is heated in an oxidizing atmosphere (like air), and its weight is monitored as the temperature increases.

The carbon nanotubes will combust at a specific temperature, while any residual metal catalyst particles (e.g., iron, cobalt) will oxidize and remain as a stable residue. The percentage of weight remaining at the end of the analysis corresponds to the amount of metallic impurity.

X-ray Diffraction (XRD)

XRD is used to confirm the crystalline structure of the material. It provides a diffraction pattern characteristic of the graphitic nature of CNTs.

The primary peaks in an XRD pattern, such as the (002) reflection, confirm the presence of well-ordered graphitic layers and can be used to estimate the average interlayer spacing in multi-walled nanotubes.

Understanding the Trade-offs and Limitations

Each characterization technique provides a specific piece of the puzzle, and it's critical to understand their limitations to avoid misinterpreting results.

Local vs. Bulk Information

Techniques like TEM provide incredibly detailed information but from a minuscule, localized portion of the sample. This small view may not be representative of the entire batch.

Conversely, bulk techniques like TGA and XRD give an average result for the entire sample but provide no information on the distribution or morphology of individual tubes.

Sample Preparation is Critical

The quality of data from any technique is highly dependent on proper sample preparation. For instance, poor dispersion for TEM analysis can lead to misleading images of agglomerated tubes.

Interpretation Requires Expertise

The data from techniques like Raman spectroscopy and XPS can be complex. Accurate interpretation requires a deep understanding of the underlying physics to distinguish meaningful signals from background noise or experimental artifacts.

Making the Right Choice for Your Goal

Selecting the right combination of techniques depends entirely on what you need to learn about your material.

- If your primary focus is basic structural confirmation: Start with SEM to see the overall morphology and TEM to verify the nanotube diameter and number of walls.

- If your primary focus is quality and defect analysis: Raman spectroscopy is the most critical tool for assessing the ID/IG ratio.

- If your primary focus is determining sample purity: TGA is the definitive method for quantifying residual metal catalyst impurities.

- If your primary focus is verifying chemical functionalization: XPS is essential for confirming the presence and nature of surface chemical groups.

Ultimately, a multi-technique approach is the only reliable path to fully understanding and validating the quality of your carbon nanotubes.

Summary Table:

| Technique | Primary Information Provided | Key Metrics |

|---|---|---|

| TEM (Microscopy) | High-resolution imaging of individual nanotubes | Diameter, number of walls, defects |

| SEM (Microscopy) | Bulk morphology and surface structure | Length, agglomeration, dispersion |

| Raman Spectroscopy | Structural quality and electronic properties | D/G band ratio (defects), RBM (diameter) |

| TGA (Thermal) | Bulk purity and catalyst content | Percent weight loss (carbon purity) |

| XPS (Spectroscopy) | Surface elemental composition and chemistry | Confirmation of functional groups |

| XRD (Diffraction) | Crystalline structure and order | Graphitic layer spacing |

Need to characterize your carbon nanotubes with confidence?

Accurate analysis is critical for successful research and development. KINTEK specializes in providing the high-quality lab equipment and consumables you need for reliable CNT characterization, from sample preparation to final analysis.

Let our expertise support your innovation. Contact our team today to discuss your specific application and find the right solutions for your laboratory.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is the difference between carbon nanotubes and graphene oxide? Choose the Right Nanomaterial for Your Application

- What are pure silicon sputtering targets? Precision Source for High-Performance Thin Films

- What nanomaterials are synthesized by chemical vapor deposition? Building High-Performance Materials with Precision

- What are the methods of deposition of ITO? A Guide to Choosing the Right Technique

- What is the effect of thickness of thin film? Master Optical, Electrical, and Mechanical Properties

- What is the growth temperature of graphene? Optimize Your CVD Process for High-Quality Films

- What are the substrates used in CVD? Key Materials for Thin Film Deposition

- How is thin film coating done? A Guide to PVD, Sol-Gel, and Precision Deposition