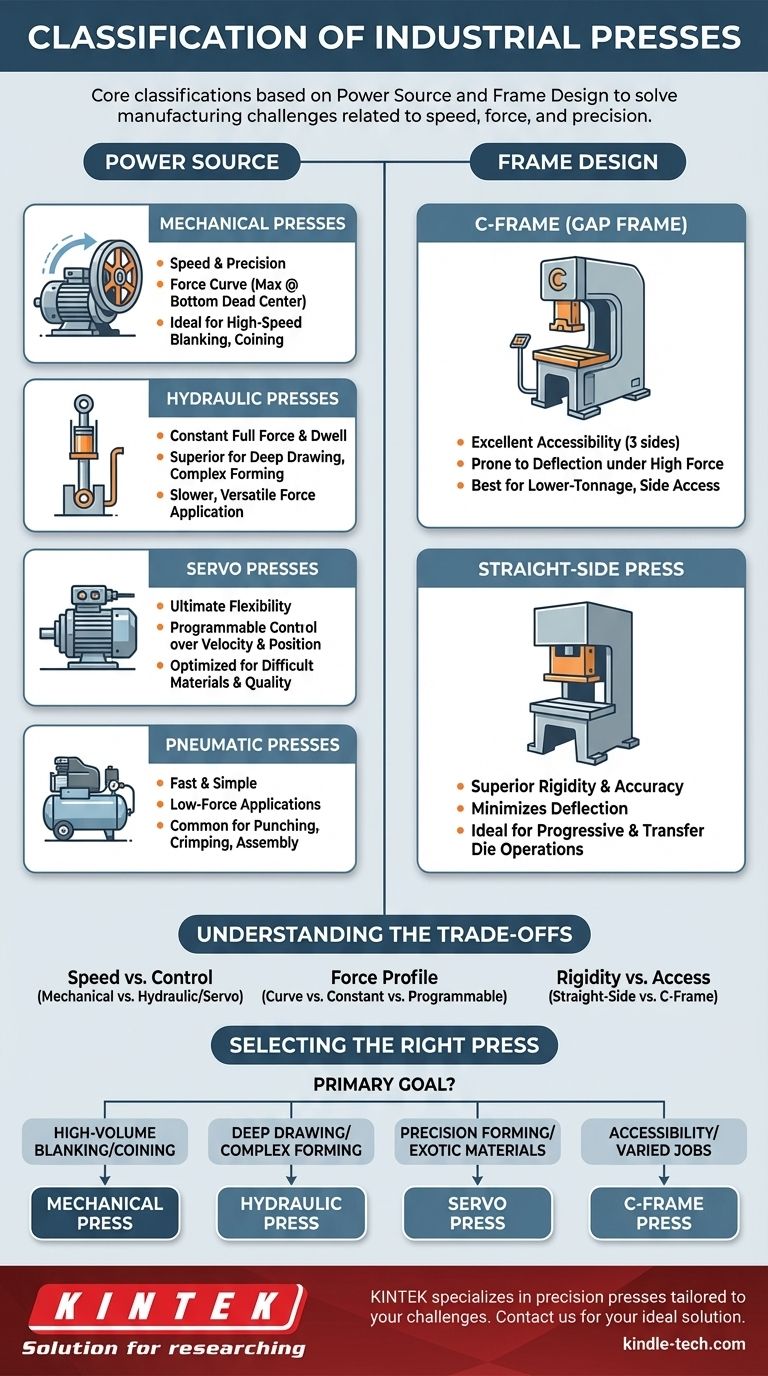

At its core, the classification of industrial presses is based on two fundamental criteria: the method used to generate force (the power source) and the physical structure of the machine (the frame design). Understanding these distinctions is crucial because each combination of power and frame is engineered to solve a specific set of manufacturing challenges related to speed, force, and precision.

The most critical distinction lies in the power source. Choosing between a mechanical, hydraulic, or servo press involves a fundamental trade-off between production speed, the consistency of force application, and the degree of control you have over the entire forming process.

The Primary Classification: Power Source

The "engine" of the press dictates its performance characteristics more than any other factor. It determines how quickly the press can cycle, how it applies force throughout its stroke, and how much control the operator has.

Mechanical Presses: Speed and Precision

Mechanical presses generate force using a motor that spins a large, heavy flywheel. This flywheel acts like a mechanical battery, storing rotational energy.

When the press is activated, a clutch connects the spinning flywheel to a crankshaft or eccentric gear, which converts the rotational motion into the vertical, linear motion of the press ram.

Force is not constant; it's delivered in a curve, reaching its maximum rated tonnage only at the very bottom of the stroke, known as bottom dead center (BDC). This makes them ideal for high-speed blanking, coining, and shallow forming operations where the work is done in a very short distance.

Hydraulic Presses: Power and Dwell

Hydraulic presses use a large piston and cylinder driven by high-pressure hydraulic fluid, powered by an electric pump. This mechanism is fundamentally different from a mechanical press.

The key advantage is that a hydraulic press can deliver its full, constant force at any point in the ram's stroke. It can also "dwell" under full pressure at the bottom of the stroke for a specified time.

This makes hydraulic presses the superior choice for applications requiring sustained pressure, such as deep drawing, molding, and forming complex parts where the material needs time to flow. They are generally slower than mechanical presses but far more versatile in force application.

Servo Presses: Ultimate Flexibility

Servo presses represent a modern evolution, combining the high speeds of mechanical presses with the control of hydraulic systems. Instead of a conventional motor and flywheel, they use a high-torque servo motor directly connected to the drive mechanism.

This direct drive gives the operator complete, programmable control over the ram's velocity and position throughout the entire stroke. You can program fast approach speeds, slow forming speeds, and quick returns, all within a single cycle.

This flexibility allows for optimizing forming processes for difficult materials, improving part quality, and reducing die wear, though they represent a higher initial investment.

Pneumatic Presses: Fast and Simple

Pneumatic presses operate on the same principle as hydraulic presses but use compressed air instead of liquid. They are much faster in their action but are limited to significantly lower-force applications.

They are commonly used for light-duty tasks like punching, crimping, and assembly operations where high tonnage is not required.

A Secondary Classification: Frame Design

The frame is the backbone of the press. Its design dictates the machine's rigidity, which directly impacts the precision of the finished part, and its accessibility for loading material and installing dies.

C-Frame (Gap Frame): Accessibility

As the name suggests, the frame is shaped like the letter "C." This design provides excellent access to the die area from three sides, making it easy to load material and set up tooling.

However, under high force, this open design is prone to "yawning" or deflection, which can compromise the alignment of the die and affect part accuracy. They are best suited for lower-tonnage work and operations where side access is critical.

Straight-Side Press: Rigidity and Accuracy

A straight-side press has a solid frame with two vertical columns, a bed, and a crown, creating a rigid, box-like structure. This design minimizes deflection even under extreme tonnage.

The superior rigidity ensures that the ram remains parallel to the bed throughout the stroke, leading to higher part accuracy, better die life, and suitability for progressive and transfer die operations. The trade-off is more limited access to the die area, typically just from the front and back.

Understanding the Trade-offs

No single press type is universally superior; the choice is always a matter of matching the machine's capabilities to the specific requirements of the job.

- Speed vs. Control: Mechanical presses are built for speed. Hydraulic and servo presses are built for control over the application of force.

- Force Profile: A mechanical press only delivers full force at the bottom of its stroke. A hydraulic press can deliver full force at any point in its stroke. A servo press can deliver a programmable force profile.

- Rigidity vs. Access: A straight-side frame offers maximum rigidity for precision work at the cost of accessibility. A C-frame offers excellent access at the cost of rigidity.

Selecting the Right Press for Your Application

Use your primary manufacturing goal to guide your decision.

- If your primary focus is high-volume blanking or coining: A mechanical press offers the cycle speed needed for maximum throughput.

- If your primary focus is deep drawing or forming complex parts: A hydraulic press provides the constant, sustained force required for the material to flow properly.

- If your primary focus is precision forming of high-strength or exotic materials: A servo press gives you the programmable control to optimize the stroke profile for perfect results.

- If your primary focus is accessibility for varied, lower-tonnage jobs: A C-frame press provides the flexibility needed for quick setups and diverse applications.

Understanding these core classifications empowers you to select not just a machine, but the right manufacturing process for your specific goal.

Summary Table:

| Classification | Key Types | Primary Characteristics |

|---|---|---|

| By Power Source | Mechanical, Hydraulic, Servo, Pneumatic | Determines speed, force control, and application flexibility |

| By Frame Design | C-Frame (Gap Frame), Straight-Side | Affects rigidity, precision, and die accessibility |

Struggling to choose the right press for your lab or production line? KINTEK specializes in providing high-performance lab equipment and consumables, including precision presses tailored to your unique manufacturing challenges. Whether you need the speed of a mechanical press, the force control of a hydraulic system, or the programmable flexibility of a servo press, our experts will help you select the ideal solution to enhance efficiency, accuracy, and throughput. Contact us today to discuss your requirements and discover how KINTEK can support your laboratory and production goals!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

People Also Ask

- Why is a laboratory hydraulic press required during the preparation of Ti3AlC2 precursor pellets?

- What role does a laboratory hydraulic press play in all-solid-state battery fabrication? Enhancing Ion Conductivity

- How does a laboratory hydraulic press contribute to the preparation of green pellets for nanostructured eutectic steel?

- What core conditions does a laboratory hydraulic press provide for solid-state electrolyte pellets? Enhance Density!

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep