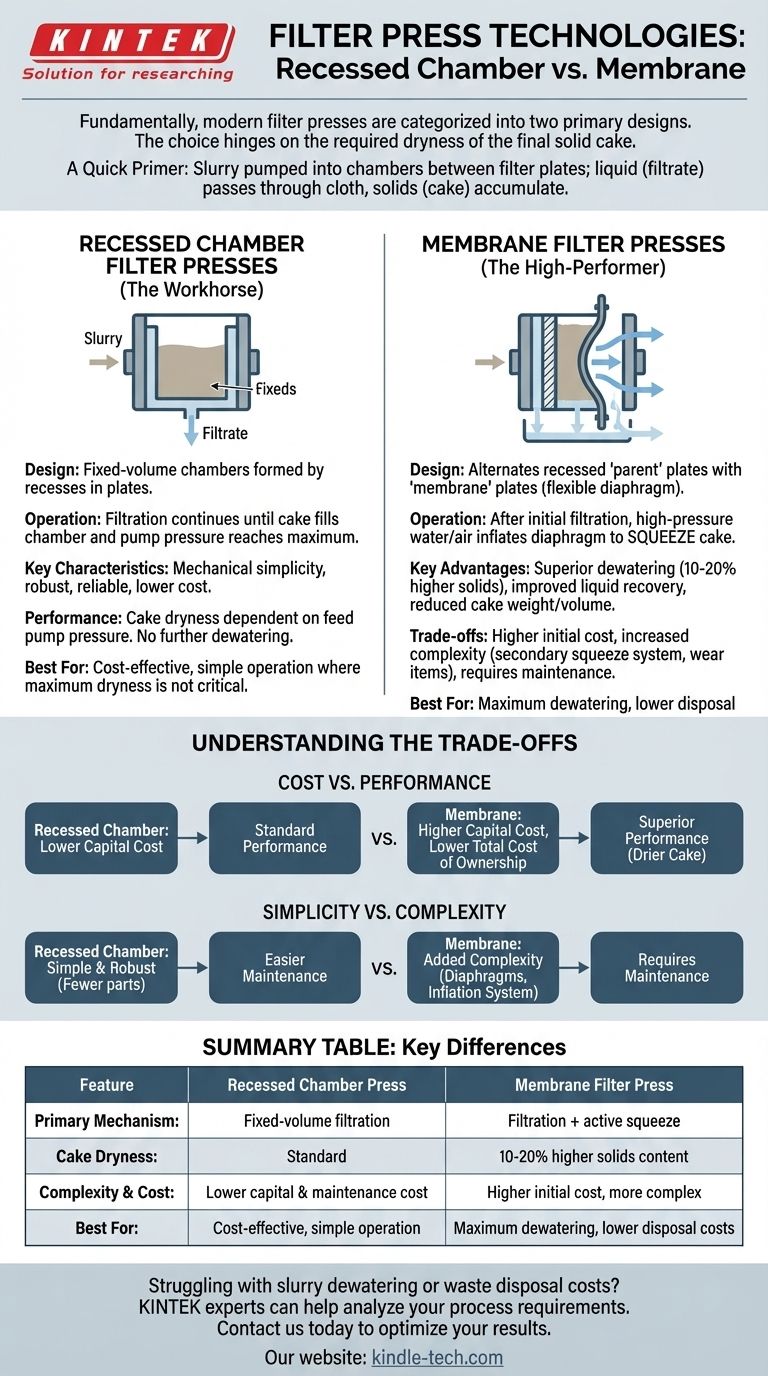

Fundamentally, modern filter presses are categorized into two primary designs: the recessed chamber filter press and the membrane filter press. While both use a frame to clamp together a series of filter plates and cloths to separate solids from liquids, the key difference lies in the technology of the plates themselves and their ability to dewater the resulting solid cake.

The choice between a recessed chamber and a membrane filter press hinges on a single factor: the required dryness of the final solid cake. Membrane presses offer superior dewatering through an active "squeeze" but come with higher complexity and cost, while recessed chamber presses are simpler and more economical for less demanding applications.

A Quick Primer: How a Filter Press Works

Before comparing designs, it's essential to understand the basic components and process that all filter presses share.

The Core Components

A filter press consists of four main parts: the frame which provides structural support, a pack of filter plates, the filter cloth that lines each plate, and the manifold of pipes and valves that directs the flow of slurry and filtrate.

The Basic Filtration Cycle

Slurry is pumped under pressure into the chambers formed between the filter plates. The liquid (filtrate) passes through the filter cloth and exits the press, while the solids (cake) are trapped and accumulate within the chambers until they are full.

The Workhorse: Recessed Chamber Filter Presses

This is the most common and straightforward type of filter press, often referred to as a "plate and frame" press, though modern designs have integrated the frame into the plate itself.

Design and Operation

In this design, each filter plate has a recess or depression on its surface. When two plates are pressed together, these recesses form a hollow chamber of a fixed volume.

The filtration cycle continues until the cake completely fills this chamber and the feed pump pressure reaches its maximum setting. At this point, the cycle is complete.

Key Characteristics

The primary characteristic of a recessed chamber press is its mechanical simplicity. It has no moving parts within the plate pack itself. This makes it robust, reliable, and generally less expensive to purchase and maintain.

Performance Limitations

The final dryness of the filter cake is entirely dependent on the pressure that the feed pump can generate. There is no way to further dewater the cake once the chamber is full, limiting the achievable solids content.

The High-Performer: Membrane Filter Presses

Membrane filter presses represent an evolution of the recessed chamber design, incorporating an active dewatering step to achieve significantly better results.

Design and Operation

A membrane press uses a mix of plates. It alternates a standard recessed "parent" plate with a "membrane" plate that has a flexible, impermeable diaphragm mounted behind the filter cloth.

After the initial filtration cycle fills the chambers, the slurry feed is stopped. High-pressure water or air is then pumped into the membrane plates, causing the diaphragm to inflate and physically squeeze the filter cake, forcing out additional liquid.

Performance Advantages

This squeezing action results in a much drier filter cake, often with 10-20% higher solids content than a recessed chamber press. This also improves liquid recovery and can significantly reduce the weight and volume of the final cake, lowering disposal costs.

Understanding the Trade-offs

Choosing between these two technologies requires a clear understanding of their respective costs and benefits.

Cost vs. Performance

Membrane presses have a higher upfront capital cost due to the more complex plates and the need for a secondary squeeze system (air compressors or water pumps).

However, they can offer a lower total cost of ownership. The dramatic reduction in cake moisture can lead to substantial savings in transportation and disposal fees or increased recovery of valuable liquid product.

Simplicity vs. Complexity

Recessed chamber presses are the definition of simple and robust. With fewer components, maintenance is more straightforward.

Membrane presses add complexity. The membranes themselves are wear items that will eventually need replacement, and the inflation system requires its own maintenance.

Cycle Time Considerations

Because of the squeeze step, membrane presses can often achieve a target cake dryness faster than recessed chamber presses. This can lead to higher overall throughput for certain applications.

Making the Right Choice for Your Goal

Your process requirements will dictate the correct technology choice.

- If your primary focus is minimizing capital cost: The recessed chamber press offers a reliable and proven solution for applications where maximum cake dryness is not critical.

- If your primary focus is maximizing cake dryness and liquid recovery: The membrane filter press provides superior performance that can lower long-term operational costs related to cake disposal or product yield.

- If your primary focus is operational simplicity and robustness: The recessed chamber design's lack of moving parts within the plate pack makes it exceptionally durable and easier to maintain.

Understanding this fundamental difference in plate technology is the key to selecting the right filter press for your specific dewatering goals.

Summary Table:

| Feature | Recessed Chamber Press | Membrane Filter Press |

|---|---|---|

| Primary Mechanism | Fixed-volume filtration | Filtration + active squeeze |

| Cake Dryness | Standard | 10-20% higher solids content |

| Complexity & Cost | Lower capital & maintenance cost | Higher initial cost, more complex |

| Best For | Cost-effective, simple operation | Maximum dewatering, lower disposal costs |

Struggling with slurry dewatering or waste disposal costs? The right filter press technology is critical for your lab's efficiency and budget. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you analyze your specific process requirements to determine whether a robust recessed chamber press or a high-performance membrane press is the ideal solution for your goals.

Contact us today via our contact form to discuss your application and discover how KINTEK's filtration solutions can optimize your results and reduce your operational costs.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.