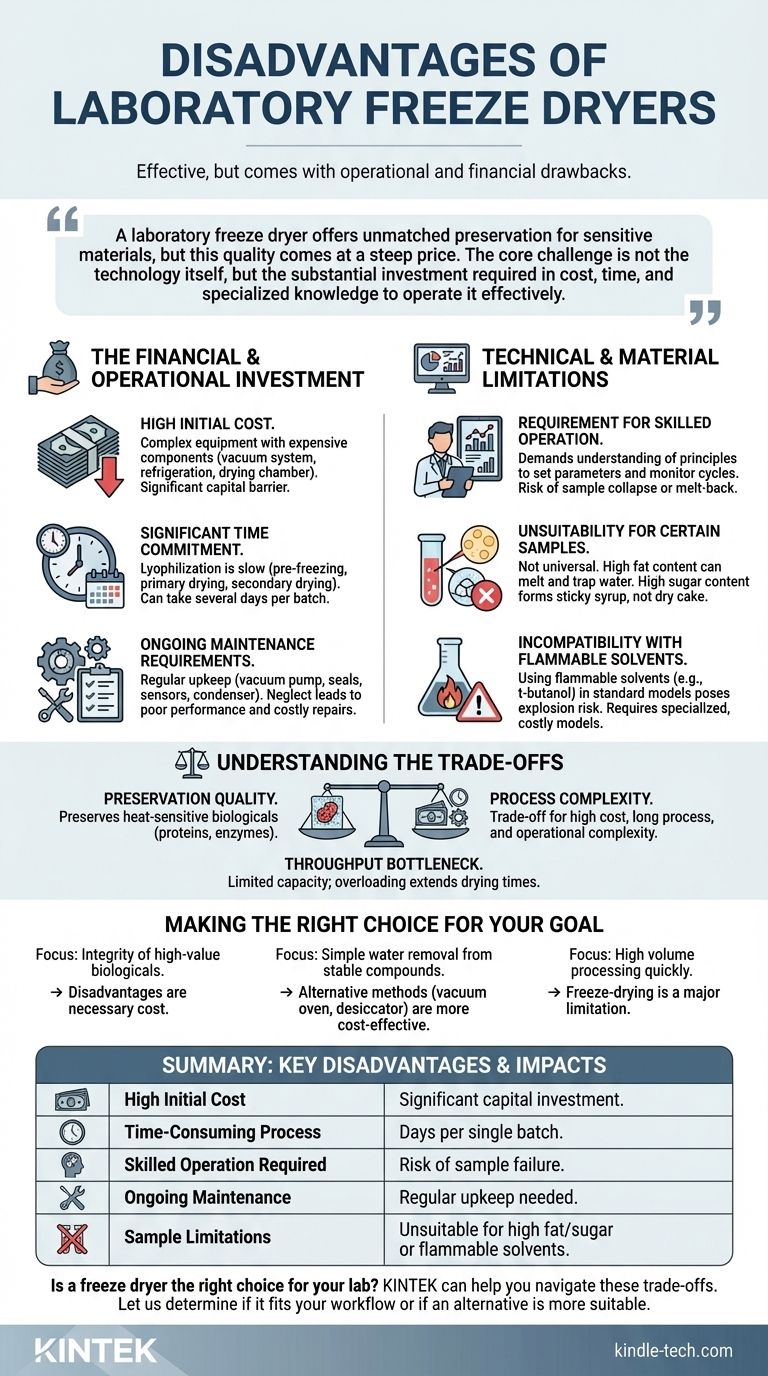

While incredibly effective, laboratory freeze dryers come with significant operational and financial drawbacks. The primary disadvantages are their high initial investment, the time-consuming nature of the lyophilization process, the need for trained personnel to operate them correctly, and their unsuitability for certain types of samples, such as those with high fat or sugar content.

A laboratory freeze dryer offers unmatched preservation for sensitive materials, but this quality comes at a steep price. The core challenge is not the technology itself, but the substantial investment required in cost, time, and specialized knowledge to operate it effectively.

The Financial and Operational Investment

The most immediate disadvantages of a freeze dryer are the resources required to purchase and run it. These are not simple, set-and-forget instruments.

High Initial Cost

A laboratory freeze dryer is a complex piece of equipment. The final price tag is driven by its essential components, including a high-performance vacuum system, a powerful refrigeration unit, and a precisely controlled drying chamber. This initial capital expenditure can be a significant barrier for many labs.

Significant Time Commitment

Freeze drying, or lyophilization, is an inherently slow process. It involves multiple stages, including pre-freezing the sample, a long primary drying phase for sublimation, and a final secondary drying phase, which can collectively take several days to complete for a single batch.

Ongoing Maintenance Requirements

To ensure performance and longevity, freeze dryers demand regular and meticulous maintenance. This includes routine care for the vacuum pump and its seals, frequent calibration of temperature and pressure sensors, and regular defrosting and cleaning of the condenser coil. Neglecting this leads to poor performance and costly repairs.

Technical and Material Limitations

Beyond the cost and time, a freeze dryer's effectiveness is constrained by both the operator's skill and the chemical properties of the sample itself.

Requirement for Skilled Operation

Properly running a freeze-drying cycle requires a solid understanding of the underlying principles. An operator must know how to prepare samples, set the correct parameters for temperature and pressure, and monitor the cycle closely to prevent sample collapse or melt-back, which can ruin the entire batch.

Unsuitability for Certain Samples

Freeze dryers are not a universal solution for dehydration. Materials with high concentrations of fat can melt and coat the sample, trapping water inside. Similarly, samples with high sugar content often have very low collapse temperatures, turning into a dense, sticky syrup instead of a porous, dry cake.

Incompatibility with Flammable Solvents

Using flammable organic solvents (like t-butanol or acetonitrile) is a common need, but it presents a serious safety risk in a standard freeze dryer. The combination of electrical components and a sealed vacuum system creates a potential for explosion, requiring specialized, and more expensive, models designed for this purpose.

Understanding the Trade-offs

The decision to use a freeze dryer involves balancing its powerful benefits against its considerable demands.

Preservation Quality vs. Process Complexity

The primary advantage of freeze-drying is its ability to preserve the structure and activity of heat-sensitive biologicals, like proteins, enzymes, and microorganisms. This superior preservation quality is the direct trade-off for the high cost, long process times, and operational complexity involved.

Throughput and Sample Volume

A laboratory freeze dryer has a finite capacity. Overloading the chamber with too many samples or too large a volume is a common mistake that extends drying times and can lead to incomplete drying. This limited throughput can become a significant bottleneck in a high-volume research environment.

Making the Right Choice for Your Goal

To determine if a freeze dryer is appropriate, you must align its capabilities with your primary objective.

- If your primary focus is preserving the integrity of high-value, heat-sensitive biologicals: The disadvantages are a necessary cost for achieving superior sample stability and longevity.

- If your primary focus is simple water removal from stable chemical compounds: A less complex and more cost-effective method, such as a vacuum oven or desiccator, is likely a better choice.

- If your primary focus is processing a high volume of samples quickly: The slow nature of freeze-drying may be a major limitation, and you must factor this throughput bottleneck into your workflow.

Ultimately, choosing a freeze dryer is a strategic decision that depends on weighing its unparalleled preservation power against its demanding operational requirements.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| High Initial Cost | Significant capital investment for the vacuum system, refrigeration unit, and chamber. |

| Time-Consuming Process | Lyophilization can take several days to complete a single batch. |

| Skilled Operation Required | Risk of sample collapse or melt-back without proper parameter setting and monitoring. |

| Ongoing Maintenance | Regular upkeep needed for vacuum pumps, seals, and condenser coils. |

| Sample Limitations | Unsuitable for materials with high fat or sugar content, or flammable solvents. |

Is a freeze dryer the right choice for your lab's preservation needs?

While freeze dryers offer unmatched sample integrity, their high costs and operational complexity require careful consideration. The experts at KINTEK can help you navigate these trade-offs. We specialize in lab equipment and consumables, providing solutions tailored to your specific research goals and budget.

Let us help you determine if a freeze dryer fits your workflow or if an alternative method is more suitable. Contact KINTEK today for a personalized consultation and discover the right preservation strategy for your laboratory.

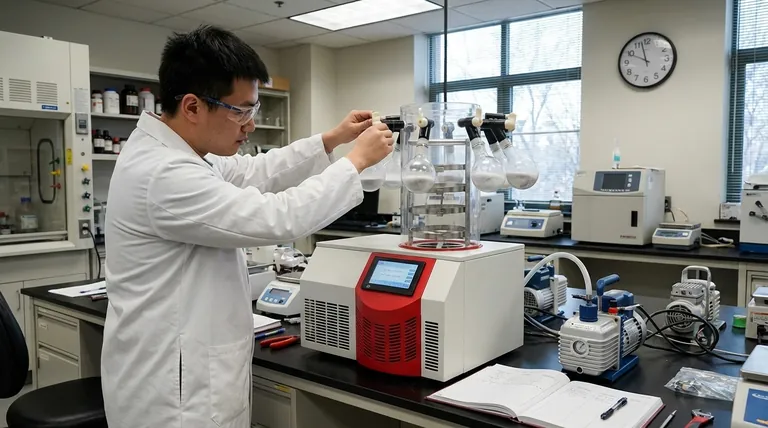

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now

- Why is a laboratory freeze-drying system essential for fermentation biomass? Preserve Sample Integrity for Analysis

- Why is a freeze dryer preferred over thermal drying for Fe-ZTA cermets? Ensure Pure, Homogeneous Slurry Processing

- What are the advantages of using freeze drying for phase change materials with biopolymer shells? Optimize Stability

- What role does a laboratory freeze dryer play in the synthesis of graphene-based electrocatalysts? Preserve 3D Structures