At its core, a hydraulic press is a machine for applying immense, controlled force. Its applications range from highly precise scientific tasks, like preparing material samples into thin pellets, to large-scale industrial processes, such as manufacturing furniture, wooden doors, and laminated boards.

The versatility of the hydraulic press stems from a single principle: its ability to amplify a small input force into a massive output force. This makes it an essential tool for any application that requires significant pressure to shape, bond, compress, or form materials.

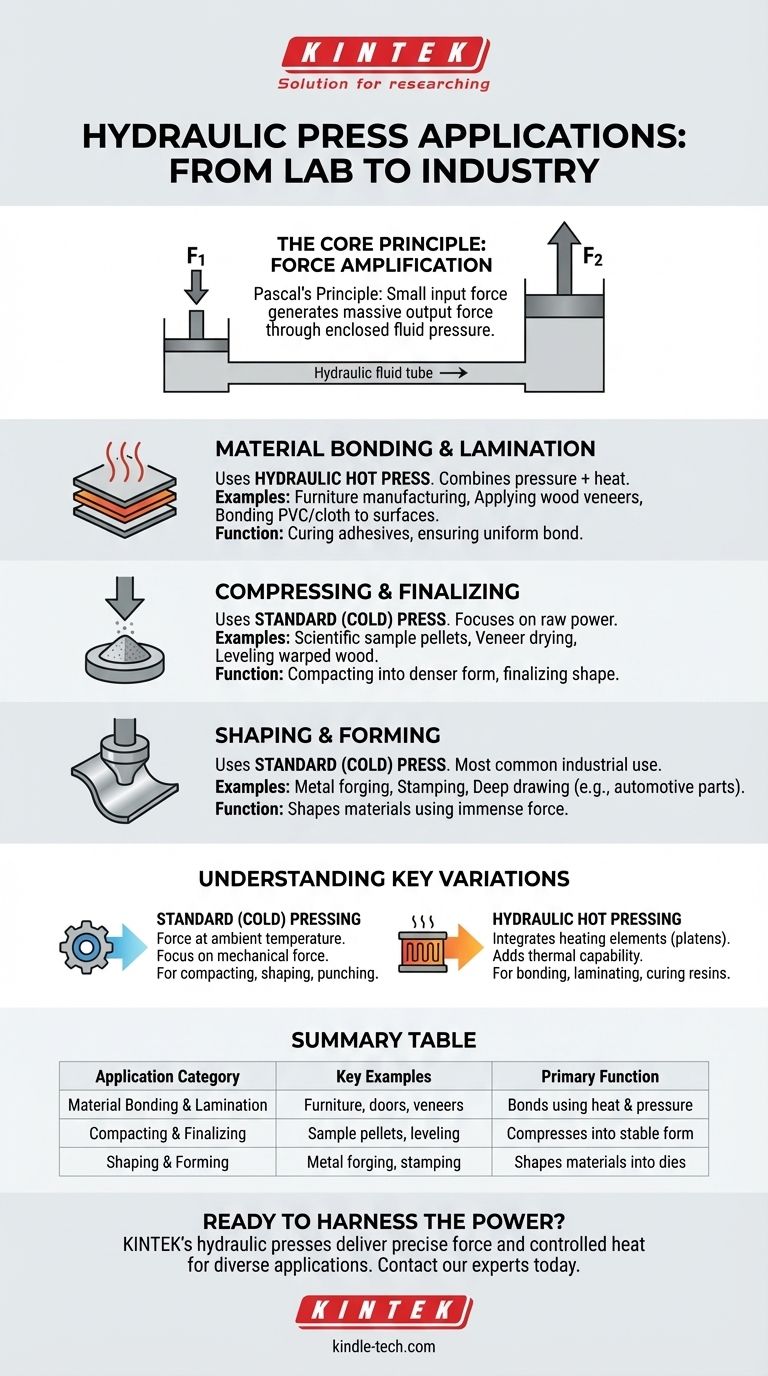

The Core Principle: Force Amplification

How It Achieves Immense Pressure

A hydraulic press operates on Pascal's Principle, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, a small force applied to a small piston creates pressure in the hydraulic fluid. This same pressure then acts on a much larger piston, generating a proportionally larger output force. This is how the machine effortlessly multiplies force.

Key Applications Across Industries

Material Bonding and Lamination

Many applications use a hydraulic hot press, which combines immense pressure with heat. This is crucial for processes that involve curing or activating adhesives.

Examples from the references include hot gluing furniture plates, applying wood veneers, or bonding decorative materials like PVC and cloth to surfaces. The press ensures uniform pressure and heat distribution for a strong, permanent bond.

Compressing and Finalizing Materials

The raw power of the press is ideal for compacting materials into a denser, more stable form.

This is seen in scientific sample preparation, where powders are compressed into solid pellets for analysis. In manufacturing, it's used for veneer drying, leveling warped wood, and finalizing designs by setting the material's shape under pressure.

Shaping and Forming

While not detailed in the provided references, the most common industrial use of hydraulic presses is for shaping metal. This includes processes like forging, stamping, and deep drawing, where metal sheets are pressed into dies to create complex parts, such as automotive body panels.

Understanding Key Variations

Standard (Cold) Pressing

A standard hydraulic press applies force at ambient temperature. Its primary purpose is to shape, punch, or compact materials where heat is not required for the process.

This is sufficient for tasks like creating sample pellets, general metal forming, or compacting waste materials. The focus is purely on the mechanical force.

Hydraulic Hot Pressing

A hot press integrates heating elements (platens) into the machine. This adds a critical capability for thermal processes.

It is indispensable for the woodworking and composites industries, where heat is necessary to cure resins, activate thermal adhesives, and laminate layers of material together effectively, as seen in furniture and door manufacturing.

Making the Right Choice for Your Goal

The type of hydraulic press application you need depends entirely on whether heat is a critical part of your process.

- If your primary focus is compacting, shaping, or punching: A standard hydraulic press that provides controlled force is the correct tool.

- If your primary focus is bonding, laminating, or curing materials: A hydraulic hot press is essential to apply both pressure and heat simultaneously.

Ultimately, understanding the function of pressure and heat is key to leveraging this powerful and versatile technology.

Summary Table:

| Application Category | Key Examples | Primary Function |

|---|---|---|

| Material Bonding & Lamination | Furniture manufacturing, door production, applying wood veneers | Bonds layers using heat and pressure to cure adhesives |

| Compacting & Finalizing | Scientific sample pellets, veneer drying, leveling warped wood | Compresses materials into a denser, stable form |

| Shaping & Forming | Metal forging, stamping, deep drawing automotive parts | Shapes materials using immense force into dies |

Ready to harness the power of a hydraulic press for your projects?

Whether you are in a research lab preparing samples or an industrial facility bonding materials, KINTEK's hydraulic presses deliver the precise force and controlled heat you need. Our equipment is engineered for reliability and performance across diverse applications, from scientific sample preparation to large-scale industrial manufacturing.

Let's discuss your specific requirements. Contact our experts today to find the perfect press for your application and enhance your productivity.

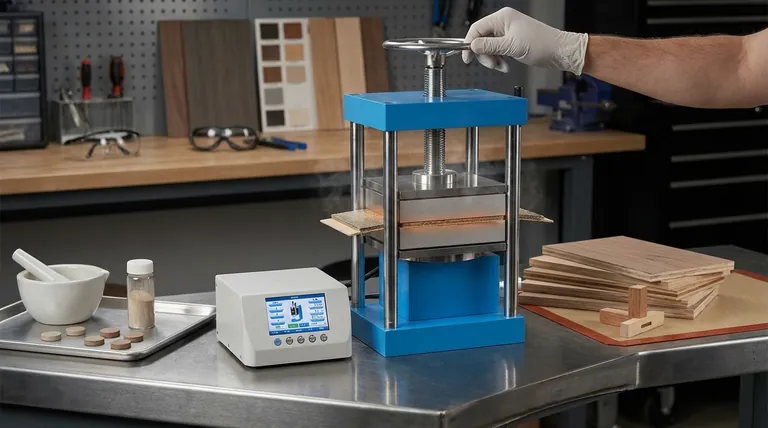

Visual Guide

Related Products

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Heat Press Machine

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- Why is a heated hydraulic press used for warm pressing NASICON green tapes? Optimize Your Solid Electrolyte Density

- How does a hydraulic hot press contribute to the fabrication of all-solid-state battery cells? Enhance Ion Transport

- How does a laboratory hydraulic hot press ensure the quality of PHBV/natural fiber composites? Expert Guide

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces

- What is the purpose of using a laboratory hydraulic press for nanocomposites? Ensure Precise Material Characterization