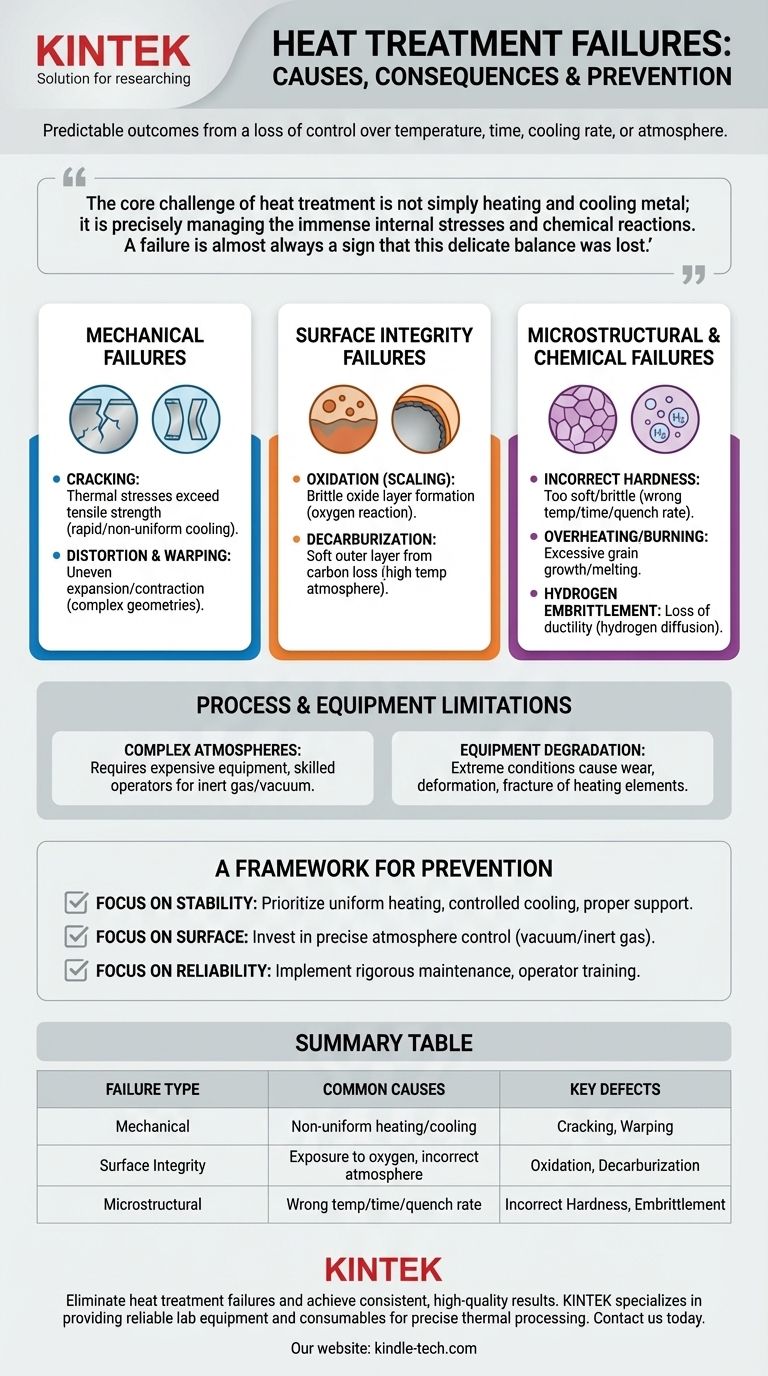

Ultimately, failures in heat treatment are not random occurrences but predictable outcomes resulting from a loss of control over temperature, time, cooling rate, or atmosphere. The most common failures manifest as physical defects like cracking and warping, or as metallurgical defects such as incorrect hardness, soft spots, and embrittlement, all of which compromise the integrity and performance of the final component.

The core challenge of heat treatment is not simply heating and cooling metal; it is precisely managing the immense internal stresses and chemical reactions that occur during the process. A failure is almost always a sign that this delicate balance was lost, leading to a component that fails to meet its engineering requirements.

The Sources of Heat Treatment Failure

Heat treatment failures can be categorized into three main areas: mechanical, surface-level, and microstructural. Each stems from a specific deviation in the tightly controlled treatment process.

Mechanical Failures: Cracking and Distortion

Cracking is the most catastrophic failure. It occurs when thermal stresses, induced by rapid or non-uniform heating and cooling, exceed the material's tensile strength.

Distortion and warping are less severe but very common. This happens when different sections of a part expand or contract at different rates, creating internal stresses that permanently change the component's shape. Complex geometries with both thick and thin sections are especially vulnerable.

Surface Integrity Failures: Oxidation and Decarburization

Oxidation, or scaling, is the formation of a brittle, flaky oxide layer on the material's surface. This occurs when the hot metal reacts with oxygen in the furnace atmosphere, leading to material loss and a poor surface finish.

Decarburization is the loss of carbon from the surface of steel. This creates a soft outer layer, which is detrimental for parts requiring high wear resistance and surface hardness. It's caused by a reaction with the furnace atmosphere at high temperatures.

Microstructural and Chemical Failures

Incorrect hardness is a common failure where the material ends up too soft or too brittle. This results from failing to reach the correct austenitizing temperature, not holding it for the required time, or using a quenching rate that is too fast or too slow for the desired microstructure (e.g., forming pearlite instead of martensite).

Overheating or burning occurs if the temperature is too high. This causes excessive grain growth or even melting at the grain boundaries, which severely weakens the material and cannot be corrected.

Hydrogen embrittlement is a chemical failure where hydrogen atoms diffuse into the metal lattice, causing a significant loss of ductility and toughness. As noted in process documentation, this is a known risk when treating certain steels in atmospheres with a high hydrogen content.

Understanding the Trade-offs: Process and Equipment Limitations

Preventing the failures above requires sophisticated equipment and processes, but these systems introduce their own set of challenges and potential points of failure.

The Complexity of Controlled Atmospheres

To prevent oxidation and decarburization, furnaces often use a controlled atmosphere (e.g., inert gas) or a vacuum. However, this solution comes with trade-offs.

Atmosphere control systems involve complicated equipment, a large initial investment, and require highly skilled operators to manage gas mixtures and pressures effectively.

The Inevitability of Equipment Degradation

The extreme conditions inside a furnace cause wear and tear on the equipment itself. This degradation can directly lead to process failures.

For example, electric heating elements in vacuum heat treatment furnaces are under constant thermal stress. Over time, they can suffer from high-temperature deformation, fracture, or even volatilization, leading to uneven heating and failed treatment cycles.

A Framework for Preventing Heat Treatment Failures

Successfully heat-treating a component requires a holistic approach that considers the material, the geometry, and the process limitations. Use these guidelines to align your strategy with your primary goal.

- If your primary focus is dimensional stability and preventing cracks: Prioritize uniform heating, controlled cooling rates, and proper support of the part within the furnace to minimize thermal gradients.

- If your primary focus is achieving specific surface hardness and finish: Invest in precise atmosphere control (vacuum or inert/reactive gases) to prevent decarburization and oxidation.

- If your primary focus is process reliability and consistency: Implement a rigorous equipment maintenance schedule and invest in comprehensive operator training to mitigate equipment failure and human error.

By understanding these failure modes, you can transform heat treatment from an operational risk into a predictable and powerful engineering tool.

Summary Table:

| Failure Type | Common Causes | Key Defects |

|---|---|---|

| Mechanical | Non-uniform heating/cooling | Cracking, Warping |

| Surface Integrity | Exposure to oxygen, incorrect atmosphere | Oxidation, Decarburization |

| Microstructural | Wrong temperature/time/quench rate | Incorrect Hardness, Embrittlement |

Eliminate heat treatment failures and achieve consistent, high-quality results.

KINTEK specializes in providing reliable lab equipment and consumables for precise thermal processing. Our furnaces and atmosphere control systems are designed to help you maintain the critical balance of temperature, time, and atmosphere, preventing common failures like cracking and decarburization.

Contact us today to discuss how our solutions can enhance your laboratory's capabilities and ensure your heat treatment processes are a predictable success.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What are the advantages of using a vacuum drying oven for combustible cartridge cases? Enhance Safety and Quality

- Which heat treatment is best? Choose the Right Process for Your Metal's Properties

- Can you use MAPP gas to braze? Yes, for small jobs with low thermal mass.

- What are the damages of carburization? Prevent Catastrophic Metal Failure in Your Equipment

- What are the disadvantages of annealing? The Critical Trade-offs in Material Strength and Cost

- What is three step sintering process? A Guide to Blending, Compacting, and Heating

- How do industrial-grade pyrolysis reactors optimize directional synthesis? Master Biomass Conversion Efficiency

- Which material is also used as a high temperature resistance material? Explore Advanced Ceramics & Alloys