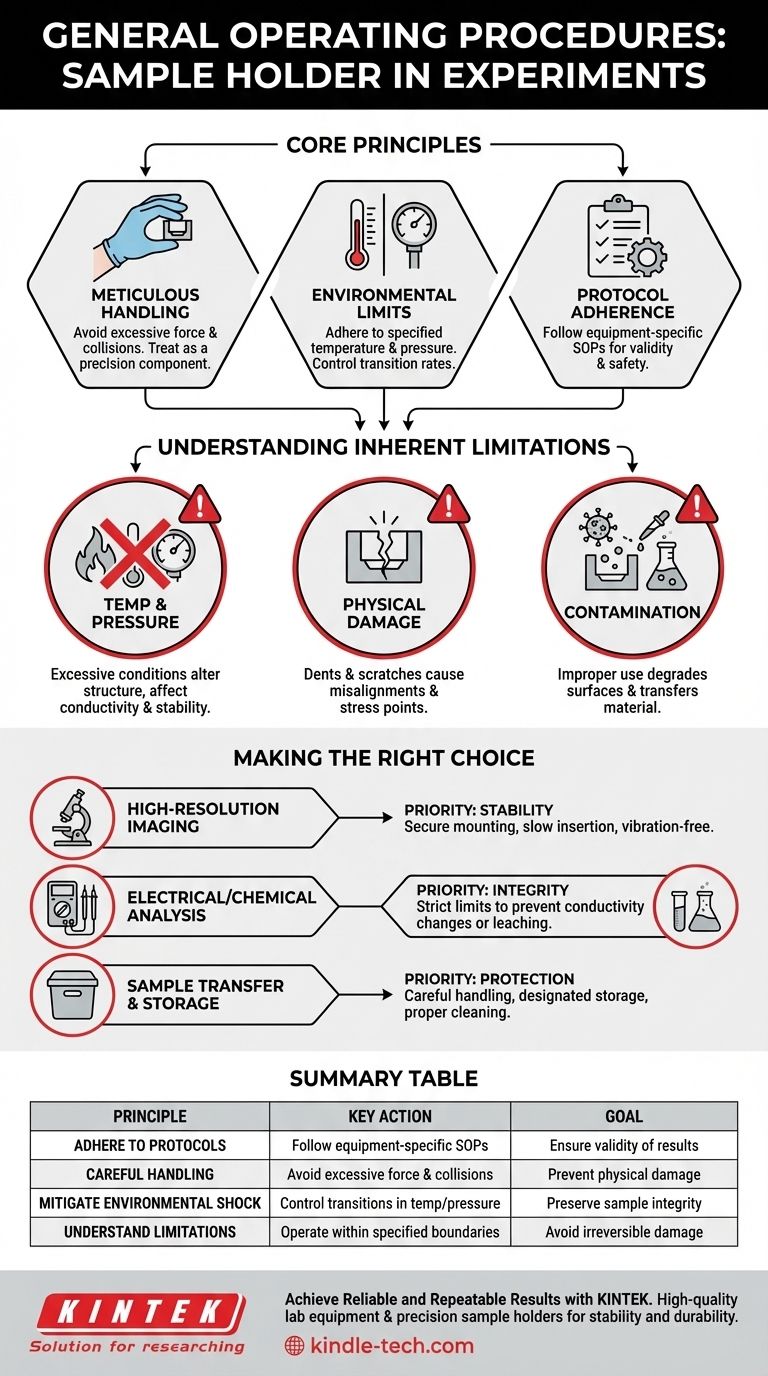

The fundamental procedures for using a sample holder revolve around three core principles: meticulous physical handling, strict adherence to environmental limits, and following the specific protocols of the associated equipment. You must avoid any improper handling, such as applying excessive force or causing collisions, and never expose the holder to conditions like high temperature or high pressure for which it was not designed.

Your primary goal when using a sample holder is not simply to transport a sample, but to preserve its integrity and that of the instrument. This is achieved by understanding that the holder is a precision component with specific physical and environmental limitations.

Core Principles of Sample Holder Operation

The correct use of a sample holder is foundational to successful and repeatable experiments. Misuse can lead to damaged equipment, compromised samples, and invalid data.

Adhere to Experiment-Specific Protocols

Every piece of laboratory equipment, from a vacuum chamber to a microscope, has its own detailed operating procedures. The sample holder is a component of that system, and its use must be governed by those specific instructions.

These protocols are designed to protect the instrument and ensure the validity of the results. Always treat the manufacturer's or lab's standard operating procedure (SOP) as the definitive guide.

The Mandate for Careful Handling

A sample holder is a precision tool, not a rugged container. It must be handled with deliberate care to prevent damage.

Avoid applying excessive force when mounting a sample or inserting the holder into an instrument. Likewise, prevent any collisions with other equipment or surfaces. Even minor impacts can cause micro-fractures or misalignments that compromise your experiment.

Mitigate Environmental Shock

Samples and holders are vulnerable to rapid changes in their environment. A critical part of proper procedure is controlling the rate of transition between different conditions.

For example, when placing a holder into a vacuum chamber, it must be inserted slowly and deliberately. Rapid movement can create airflow strong enough to dislodge the sample, rendering the entire preparation useless. This principle applies to any change in pressure, temperature, or atmosphere.

Understanding the Inherent Limitations

To use a sample holder effectively, you must understand its operational boundaries. Exceeding these limits can cause irreversible damage and invalidate your results.

Strict Temperature and Pressure Boundaries

Most standard sample holders are designed exclusively for use at room temperature and atmospheric pressure.

Subjecting the holder to high temperature or high pressure can permanently alter its physical structure. This can affect its critical properties, such as electrical conductivity and chemical stability, leading to inaccurate measurements and potential contamination of your sample.

The Risk of Physical Damage

Damage to the holder from improper handling is a primary cause of experimental failure. Small dents, scratches, or bends may seem cosmetic but can have significant consequences.

A damaged holder may not sit correctly within the instrument, leading to focus issues in microscopy or inconsistent measurements in spectroscopy. It can also create stress points on the sample itself.

Preventing Sample Contamination

The holder is in direct contact with your sample, making it a potential source of contamination. Damage, improper cleaning, or chemical alteration of the holder's surface can transfer unwanted materials to your sample.

Using a holder outside of its specified temperature range, for instance, can degrade its surface materials and compromise the chemical stability of your experiment.

Making the Right Choice for Your Goal

Proper procedure is not a single checklist but a mindset adapted to your specific objective. The following guidelines will help you align your handling with your experimental needs.

- If your primary focus is high-resolution imaging (e.g., SEM, TEM): Your priority is absolute physical stability. Ensure the sample is mounted securely without stress and that insertion is slow and vibration-free.

- If your primary focus is electrical or chemical analysis: Your priority is preserving the holder's material integrity. Strictly observe all temperature and pressure limits to prevent changes in conductivity or chemical leaching.

- If your primary focus is sample transfer and storage: Your priority is preventing physical damage and contamination. Handle the holder carefully, use designated storage containers, and ensure it is cleaned appropriately between uses.

Ultimately, treating the sample holder with the same respect as the most sensitive part of your instrument is the key to achieving reliable and repeatable scientific results.

Summary Table:

| Principle | Key Action | Goal |

|---|---|---|

| Adhere to Protocols | Follow equipment-specific SOPs | Ensure validity of results |

| Careful Handling | Avoid excessive force and collisions | Prevent physical damage |

| Mitigate Environmental Shock | Control transitions in temperature/pressure | Preserve sample integrity |

| Understand Limitations | Operate within specified boundaries | Avoid irreversible damage |

Achieve Reliable and Repeatable Results with KINTEK

Proper sample handling is the foundation of any successful experiment. KINTEK specializes in high-quality lab equipment and consumables, including precision sample holders designed for stability and durability. Our products help you maintain sample integrity, prevent contamination, and ensure accurate data collection.

Let us support your laboratory's success.

Contact our experts today to find the perfect sample handling solutions for your specific application, from high-resolution imaging to sensitive chemical analysis.

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the factors that affect melting and boiling point? Unlock the Science of Phase Transitions

- Why is an airtight sample holder with a beryllium window required for XRD of sulfide solid electrolytes?

- What are the limitations of the IR spectroscopy? Understanding Its Boundaries for Accurate Analysis

- Does higher heat capacity mean higher melting point? Unraveling the Critical Difference

- What is the minimum sample required for XRD analysis? Optimize Your Material Analysis