The primary hazards of a hydraulic press stem directly from the immense force it generates. These dangers include catastrophic crushing injuries at the point of operation, the violent ejection of shattering parts or tooling, and severe skin-penetrating injuries from high-pressure hydraulic fluid leaks. Even a seemingly small benchtop press can generate tens of thousands of pounds of force, creating a significant risk zone that demands respect and caution.

The core danger of a hydraulic press lies in its two forms of stored energy: the mechanical force concentrated at the die and the high-pressure potential energy within the hydraulic system itself. An uncontrolled release of either form of energy can have immediate and severe consequences.

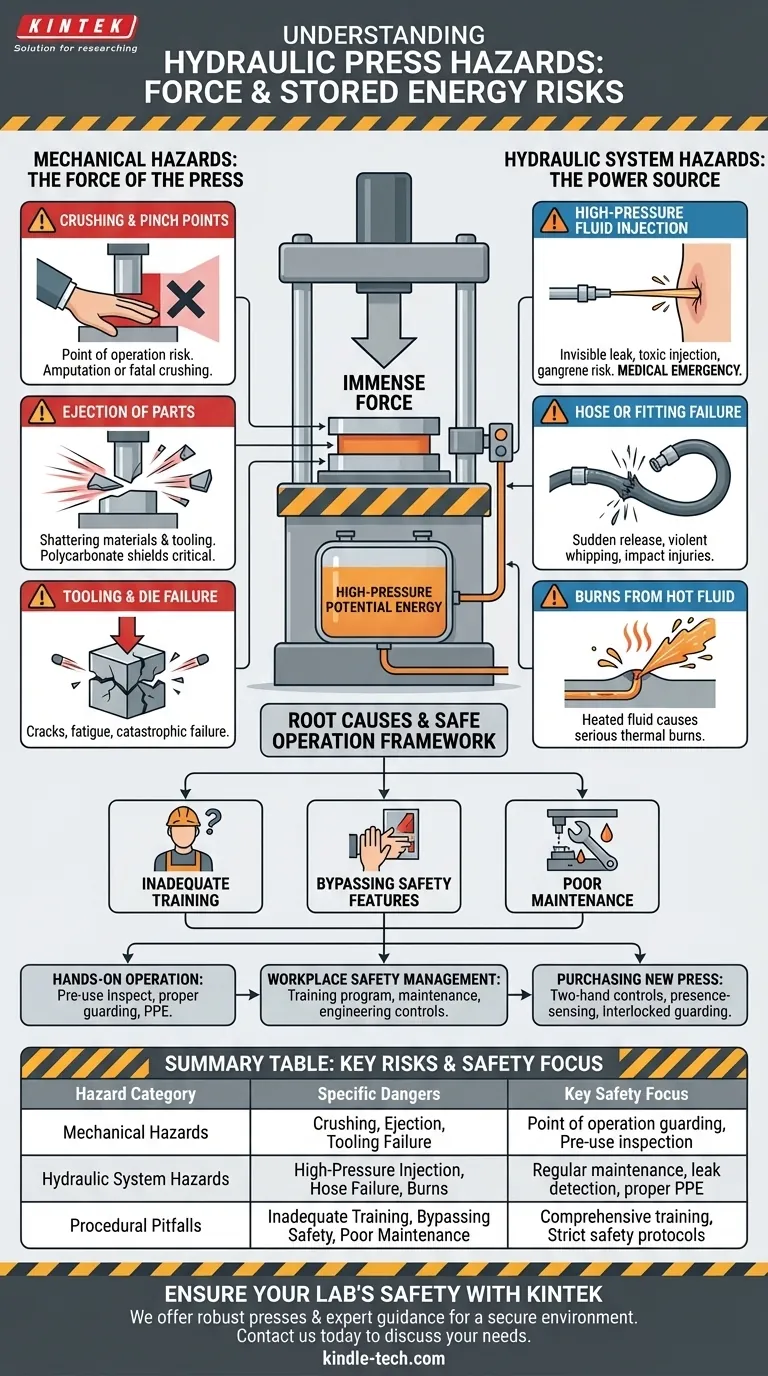

Mechanical Hazards: The Force of the Press

The most apparent dangers are related to the physical movement and force applied by the machine's ram and platens.

Crushing and Pinch Points

A hydraulic press is designed to crush, form, and shape materials. Any body part caught between the moving ram and the fixed bed, or between tooling components, will be subjected to the same force.

This can result in amputation or fatal crushing injuries. The area between the platens is known as the point of operation, and it is the most significant mechanical hazard zone.

Ejection of Parts or Material

When a workpiece or the tooling itself is subjected to extreme force, it can fail unpredictably. Brittle materials can shatter, sending sharp fragments flying at high velocity.

Even if the workpiece is sound, improper alignment can cause it to slip and be ejected from the press. This is why safety shields, often made of strong polycarbonate, are a critical safety feature.

Tooling and Die Failure

The dies and tooling used in a press are hardened but can still develop cracks or fatigue over time. A catastrophic failure of a die set under load can create dangerous projectiles, turning the tools themselves into shrapnel.

Hydraulic System Hazards: The Power Source

The hydraulic system that powers the press presents its own distinct and often underestimated set of dangers.

High-Pressure Fluid Injection

This is one of the most severe and insidious hydraulic press hazards. A pinhole leak in a hydraulic line can release a nearly invisible stream of fluid at thousands of PSI.

If this stream contacts an operator's skin, it can easily penetrate it, injecting toxic hydraulic fluid deep into the tissue. This is a medical emergency that can lead to gangrene and amputation if not treated immediately by a specialist aware of injection injuries. Never use your hand to check for hydraulic leaks.

Hose or Fitting Failure

A sudden rupture of a hydraulic hose or fitting results in a violent release of high-pressure fluid. This can cause the hose to whip around with incredible force, causing severe impact injuries.

Burns from Hot Fluid

As a hydraulic system operates, the fluid heats up. A line rupture or fluid leak can spray hot oil, causing serious thermal burns on contact with skin.

Understanding the Pitfalls: The Root Causes of Accidents

Most incidents are not caused by spontaneous machine failure but by a breakdown in safe operating procedures and machine safeguarding.

Inadequate Operator Training

An operator who does not fully understand the machine's power, its specific hazards, and its safety features is a danger to themselves and others. Training must cover pre-use inspection, proper operation, and emergency shutdown procedures.

Bypassing Safety Features

Safety features like two-hand controls, light curtains, and physical guards are designed to keep the operator out of the danger zone during a cycle. Disabling or bypassing these features for the sake of convenience or speed is a primary cause of severe injury.

Poor Maintenance and Inspection

Ignoring a small hydraulic leak, failing to inspect tooling for cracks, or operating a press with worn hoses is a direct path to failure. A rigorous and documented maintenance schedule is essential for preventing the uncontrolled release of energy.

A Framework for Safe Operation

To mitigate these hazards, you must implement a multi-layered safety strategy that addresses the machine, the operator, and the process.

- If your primary focus is hands-on operation: Prioritize pre-use inspections, always use appropriate guarding and Personal Protective Equipment (PPE), and never place any part of your body within the point of operation.

- If your primary focus is workplace safety management: Implement a comprehensive program that includes documented operator training, scheduled maintenance, and engineering controls like fixed guarding or light curtains.

- If your primary focus is purchasing a new press: Specify and invest in modern safety features like two-hand anti-tie-down controls, presence-sensing devices, and robust, interlocked physical guarding.

Understanding these hazards is the first and most critical step toward creating a safe and productive environment.

Summary Table:

| Hazard Category | Specific Dangers | Key Safety Focus |

|---|---|---|

| Mechanical Hazards | Crushing/Pinch Points, Ejection of Parts, Tooling Failure | Point of operation guarding, pre-use inspection |

| Hydraulic System Hazards | High-Pressure Fluid Injection, Hose/Fitting Failure, Hot Fluid Burns | Regular maintenance, leak detection, proper PPE |

| Procedural Pitfalls | Inadequate Training, Bypassing Safety Features, Poor Maintenance | Comprehensive operator training, strict safety protocols |

Ensure your lab's safety with the right equipment and support. The hazards of hydraulic presses are significant, but they can be effectively managed with proper safeguards and training. KINTEK specializes in lab equipment and consumables, offering robust hydraulic presses and expert guidance to help you mitigate risks and create a secure working environment for your team.

Contact us today via our [#ContactForm] to discuss your specific laboratory needs and discover how our solutions can protect your operators and enhance your productivity.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy