In countless industrial settings, cold working is the fundamental process used to shape and strengthen metals without heat. It is the go-to method for manufacturing high-strength components with excellent dimensional accuracy, from everyday items like steel screws and aluminum foil to critical automotive parts and electrical wiring. These applications leverage cold work to produce parts that are stronger, more precise, and have a better surface finish than those made by hot forming processes.

The true industrial value of cold working is not just in its ability to shape metal. Its core advantage lies in strain hardening—a mechanism that simultaneously strengthens the material while achieving tight dimensional tolerances and a superior surface finish, a combination that alternative methods cannot easily replicate.

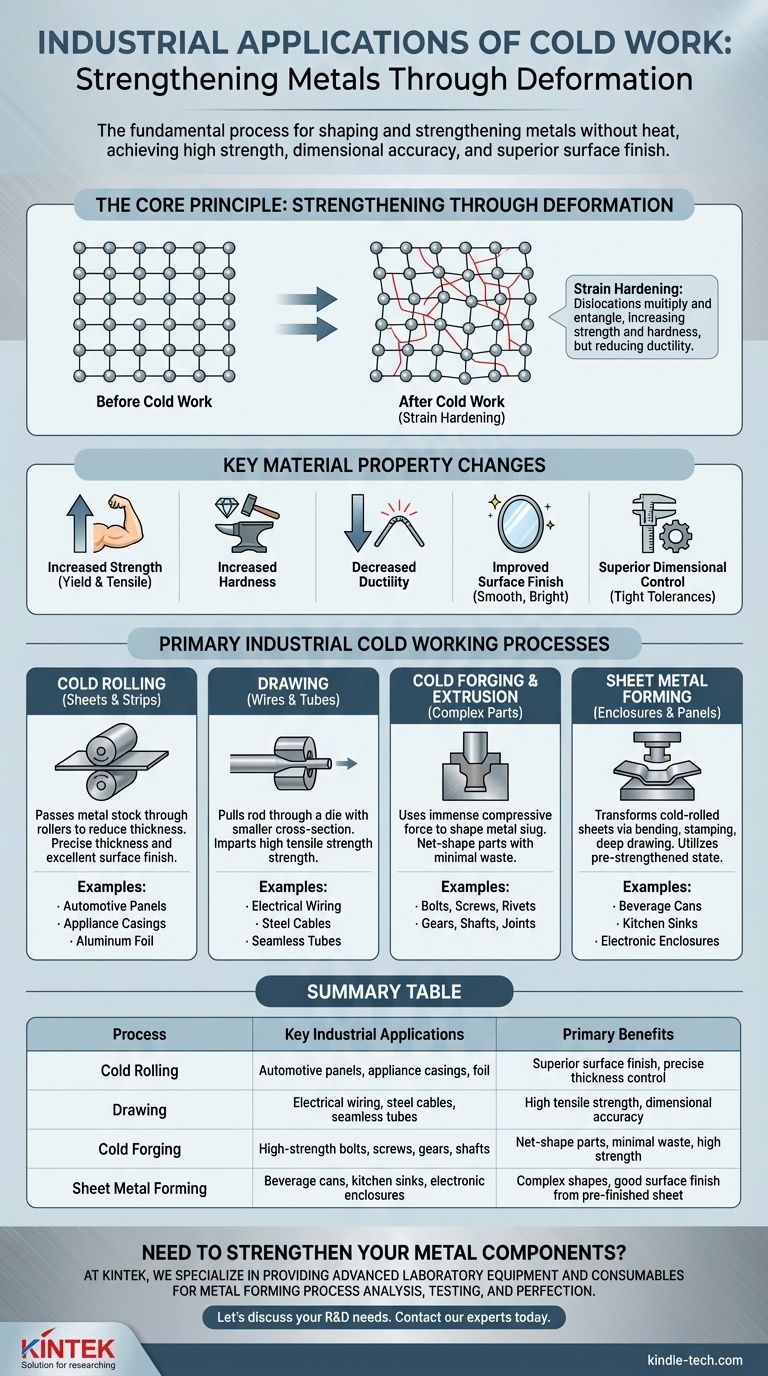

The Core Principle: Strengthening Through Deformation

To understand cold work's applications, you must first understand the principle that makes it so valuable. The process fundamentally alters a metal's internal structure to enhance its properties.

What is Cold Working?

Cold working is the plastic deformation of a metal at a temperature below its recrystallization point. Unlike hot working, where high temperatures allow the material's crystal structure to reform and soften, cold working forces the crystals to deform permanently.

This forces a trade-off: the metal becomes stronger but also less ductile.

The Mechanism of Strain Hardening

At a microscopic level, deforming the metal creates and moves imperfections in its crystal lattice called dislocations. As cold work continues, these dislocations multiply and become entangled, impeding each other's movement.

This entanglement is the source of strain hardening (or work hardening). It becomes progressively harder to deform the metal, which translates to a measurable increase in its strength and hardness.

Key Material Property Changes

The direct results of cold working are predictable and essential for its applications:

- Increased Strength: Both yield strength and ultimate tensile strength are significantly improved.

- Increased Hardness: The material becomes more resistant to indentation and surface wear.

- Decreased Ductility: The metal's ability to stretch or deform without fracturing is reduced.

- Improved Surface Finish: The process produces a smooth, bright surface, often eliminating the need for secondary polishing.

- Superior Dimensional Control: Without the thermal expansion and contraction seen in hot working, cold-worked parts can be made to very tight tolerances.

Primary Industrial Cold Working Processes

These property changes are leveraged across several key manufacturing processes, each tailored for a specific type of product.

Cold Rolling: For Sheets and Strips

Cold rolling involves passing metal stock through a pair of rollers to reduce its thickness. It is the standard process for producing steel sheets for car bodies, aluminum foil for packaging, and stainless steel panels for appliances.

The primary goals are to achieve a precise thickness and an excellent, smooth surface finish that is ready for painting or coating.

Drawing: For Wires and Tubes

In drawing, a metal rod is pulled through a die with a smaller cross-section. This is the essential method for manufacturing electrical wiring (copper and aluminum), steel cables, and seamless tubes for fluid transport.

Strain hardening is critical here, as it imparts the high tensile strength required for wires and cables to resist breaking under load.

Cold Forging & Extrusion: For Complex Parts

Cold forging and extrusion use immense compressive force to shape a metal slug within a die. This is the dominant method for mass-producing high-strength fasteners like bolts, screws, and rivets.

It is also used for more complex automotive components like gears, shafts, and joints. The process is valued for creating net-shape or near-net-shape parts, which minimizes material waste and machining costs.

Sheet Metal Forming: For Enclosures and Panels

Processes like bending, stamping, and deep drawing transform cold-rolled sheets into finished goods. These methods are used to create everything from beverage cans and kitchen sinks to car door panels and computer casings.

The pre-strengthened and finished state of the cold-rolled sheet is carried through to the final product.

Understanding the Trade-offs

Choosing cold work is an engineering decision with clear benefits and significant limitations. Objectivity requires acknowledging its downsides.

The Ductility Limit

As a metal is cold-worked, its ductility decreases. There is a limit to how much deformation can occur before the material becomes too brittle and risks cracking. For complex shaping, multiple stages with intermediate annealing (a heat treatment to restore ductility) may be necessary, adding cost and complexity.

High Force and Power Requirements

Deforming metal at room temperature requires substantially more force than deforming it when hot and malleable. This necessitates larger, more powerful, and more expensive machinery.

The Problem of Residual Stress

Cold working induces internal stresses within the material. While sometimes beneficial (like in shot peening to improve fatigue life), unwanted residual stresses can cause parts to warp over time or fail prematurely. A post-process stress-relief heat treatment is often required for dimensionally critical components.

Material Constraints

Only highly ductile metals are suitable for extensive cold working. Materials like most copper alloys, aluminum alloys, low-carbon steels, and stainless steels are excellent candidates. Brittle materials, such as cast iron or high-carbon steels, will fracture rather than deform.

Making the Right Choice for Your Goal

The decision to use cold working hinges on a clear understanding of your final component's requirements. It is a precise tool for a specific set of engineering goals.

- If your primary focus is maximum strength and precision in mass production: Cold forging and drawing are ideal for parts like high-strength bolts, electrical wire, and structural rods.

- If your primary focus is a superior surface finish on sheet material: Cold rolling is the definitive process for creating automotive panels, appliance casings, and packaging foils.

- If your primary focus is creating a very large or intricate shape from a single billet: Hot working is often more practical, as it allows for massive deformation without the risk of fracture.

- If your primary focus is improving the fatigue life of a critical component: A specialized surface treatment like shot peening is a targeted cold work process designed specifically for this outcome.

Ultimately, selecting the right manufacturing process requires a deliberate evaluation of the trade-offs between strength, precision, ductility, and cost.

Summary Table:

| Process | Key Industrial Applications | Primary Benefits |

|---|---|---|

| Cold Rolling | Automotive panels, appliance casings, aluminum foil | Superior surface finish, precise thickness control |

| Drawing | Electrical wiring, steel cables, seamless tubes | High tensile strength, dimensional accuracy |

| Cold Forging | High-strength bolts, screws, gears, shafts | Net-shape parts, minimal waste, high strength |

| Sheet Metal Forming | Beverage cans, kitchen sinks, electronic enclosures | Complex shapes, good surface finish from pre-finished sheet |

Need to Strengthen Your Metal Components?

Does your manufacturing process require parts with superior strength, precise dimensional tolerances, and an excellent surface finish? The cold working techniques detailed above are essential for producing high-performance components in industries from automotive to electronics.

At KINTEK, we specialize in providing the advanced laboratory equipment and consumables needed to analyze, test, and perfect these metal forming processes. Whether you are developing new alloys or optimizing production parameters, our solutions help you achieve the material properties critical for your success.

Let's discuss how we can support your R&D and quality control efforts. Contact our experts today to find the right equipment for your laboratory's needs.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy