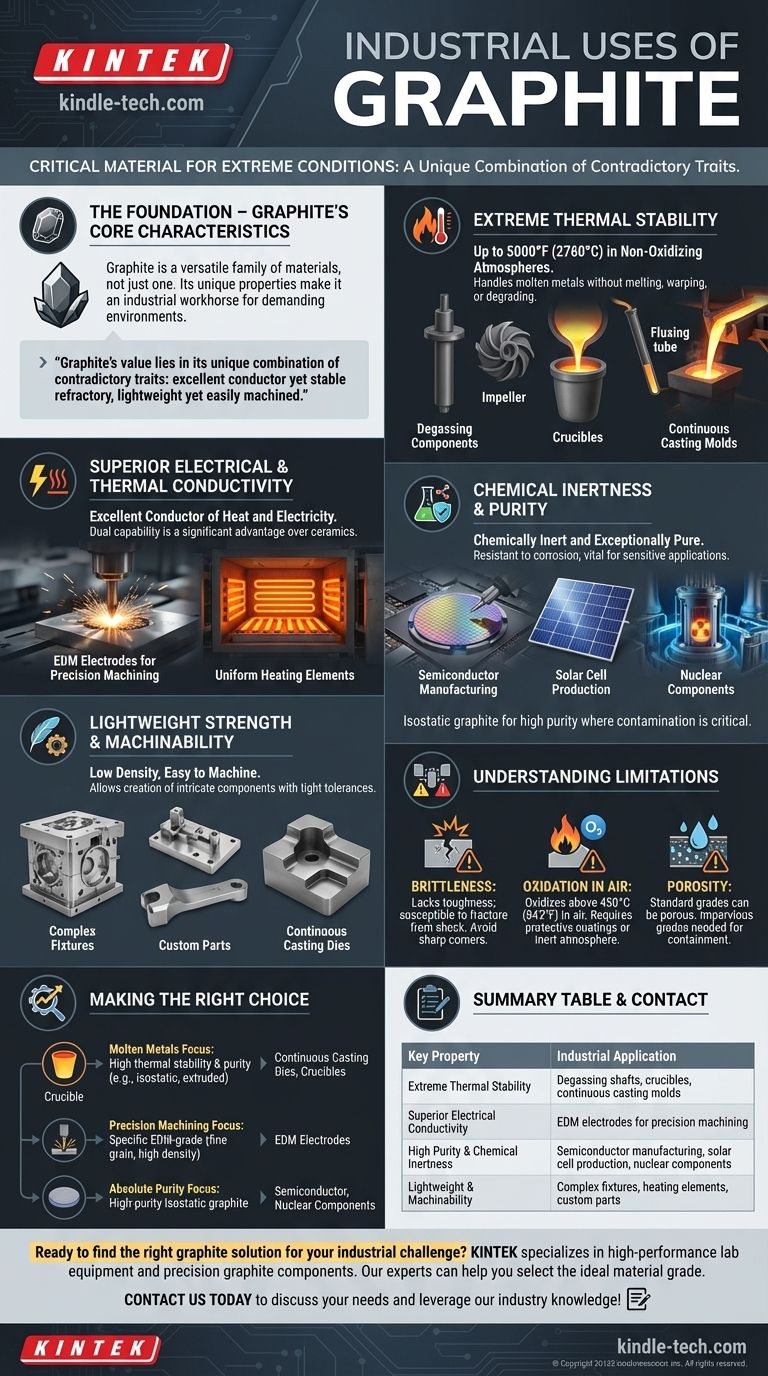

In industrial settings, graphite is a critical material used for its exceptional performance under extreme conditions. Its applications range from metallurgical processes like degassing and continuous casting to high-purity components in the semiconductor, solar, and nuclear industries, and precision electrodes for electrical discharge machining (EDM).

Graphite’s value isn't just in a single property, but in its unique combination of contradictory traits. It is one of the few materials that is both an excellent thermal/electrical conductor and a highly stable refractory material, all while being lightweight and easily machined.

The Foundation: Why Graphite is an Industrial Workhorse

Graphite is not a single material but a family of materials whose properties can be tailored for specific tasks. Its widespread adoption is due to a set of core physical characteristics that make it uniquely suitable for demanding industrial environments.

Extreme Thermal Stability

Graphite has one of the highest sublimation points of any element, maintaining its structural integrity at temperatures up to 5000°F (around 2760°C) in non-oxidizing atmospheres.

This makes it indispensable for high-temperature metallurgical applications. Components like degassing shafts, impellers, fluxing tubes, and crucibles rely on graphite to handle molten metals without melting, warping, or degrading.

Superior Electrical and Thermal Conductivity

Unlike most refractory ceramics, graphite is an excellent conductor of both heat and electricity. This dual capability is a significant advantage.

Its ability to conduct electricity allows it to be used as a long-lasting electrode in Electrical Discharge Machining (EDM), a process for cutting and shaping hard metals. Its thermal conductivity is also vital for creating uniform heating elements in industrial furnaces.

Chemical Inertness and Purity

Graphite is chemically inert and does not readily react with other elements or compounds, especially acids and bases. This resistance to corrosion is critical.

Furthermore, it can be refined to exceptionally high purity levels. This is why isostatic graphite is a dominant material in the semiconductor, solar, and nuclear industries, where even minuscule contamination can ruin a process or create safety risks.

Lightweight Strength and Machinability

Despite its high-temperature resilience, graphite has a low density and is relatively easy to machine into complex shapes with tight tolerances.

This allows for the creation of intricate components like casting molds, continuous casting dies, and precision fixtures that would be difficult or prohibitively expensive to produce from other refractory materials.

Understanding the Trade-offs and Limitations

No material is perfect. While graphite is incredibly versatile, a technical advisor must also be clear about its operational constraints to ensure proper application and avoid failure.

Brittleness

Graphite is a brittle material, meaning it lacks the toughness of metals. It is susceptible to fracture from sharp impacts or high mechanical shock. Designs must account for this by avoiding sharp corners and protecting against impact.

Oxidation in Air

While graphite excels in vacuum or inert atmospheres, its high-temperature stability plummets in the presence of oxygen. It will begin to oxidize (essentially, burn away) at temperatures typically above 450°C (842°F). Protective coatings or controlled atmospheres are often required for high-temperature use in air.

Porosity

Standard grades of graphite can be porous, which may be undesirable in applications requiring containment of liquids or gases. However, specialized manufacturing processes can produce "impervious" graphite grades that are sealed to overcome this limitation for use in heat exchangers and chemical processing equipment.

Making the Right Choice for Your Goal

The "right" graphite depends entirely on the industrial problem you are trying to solve. The material's grade and properties must be matched to the application's demands.

- If your primary focus is handling molten metals: You need graphite with high thermal stability and purity, such as isostatic or extruded grades used for continuous casting dies, crucibles, and degassing components.

- If your primary focus is precision electrical machining: You require a specific EDM-grade graphite with fine grain, high density, and consistent electrical resistivity for predictable and clean cuts.

- If your primary focus is absolute purity and chemical inertness: You must use high-purity isostatic graphite, the standard for manufacturing semiconductor crystals and nuclear reactor components.

Understanding these core properties and trade-offs empowers you to select and implement graphite not just as a component, but as a strategic solution.

Summary Table:

| Key Property | Industrial Application |

|---|---|

| Extreme Thermal Stability | Degassing shafts, crucibles, continuous casting molds |

| Superior Electrical Conductivity | EDM electrodes for precision machining |

| High Purity & Chemical Inertness | Semiconductor manufacturing, solar cell production, nuclear components |

| Lightweight & Machinability | Complex fixtures, heating elements, custom parts |

Ready to find the right graphite solution for your industrial challenge? KINTEK specializes in high-performance lab equipment and consumables, including precision graphite components for metallurgy, EDM, and high-purity applications. Our experts can help you select the ideal material grade to enhance efficiency, durability, and results. Contact us today to discuss your needs and leverage our industry knowledge!

Visual Guide

Related Products

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the purpose of a graphite furnace? Achieve Extreme Temperatures for Advanced Materials

- What are the advantages of graphite? Unlock Superior Performance in High-Temperature Processes

- What happens to graphite when heated? Unlock Its High-Temperature Potential or Risk Oxidation

- What are the interferences of graphite furnace? Overcome Matrix & Spectral Issues for Accurate GFAAS

- What is the process of isostatic graphite manufacturing? Achieve Unmatched Material Uniformity and Performance

- Why is graphite the best conductor of heat? Understanding Its Directional Thermal Superiority

- How is synthetic graphite manufactured? A Deep Dive into the High-Temperature Process

- What is a graphite furnace? Unlock Extreme Temperatures and Purity for Advanced Materials