The key safety guidelines for an electrolytic cell revolve around diligent preparation, constant awareness during operation, and proper maintenance. This involves consistently using personal protective equipment (PPE), thoroughly inspecting the cell for physical and electrical integrity before each use, and maintaining a controlled, well-ventilated environment to mitigate chemical and electrical hazards.

True operational safety is not a checklist, but a mindset. It requires anticipating risks from chemical exposure, electrical hazards, and equipment failure before, during, and after every procedure.

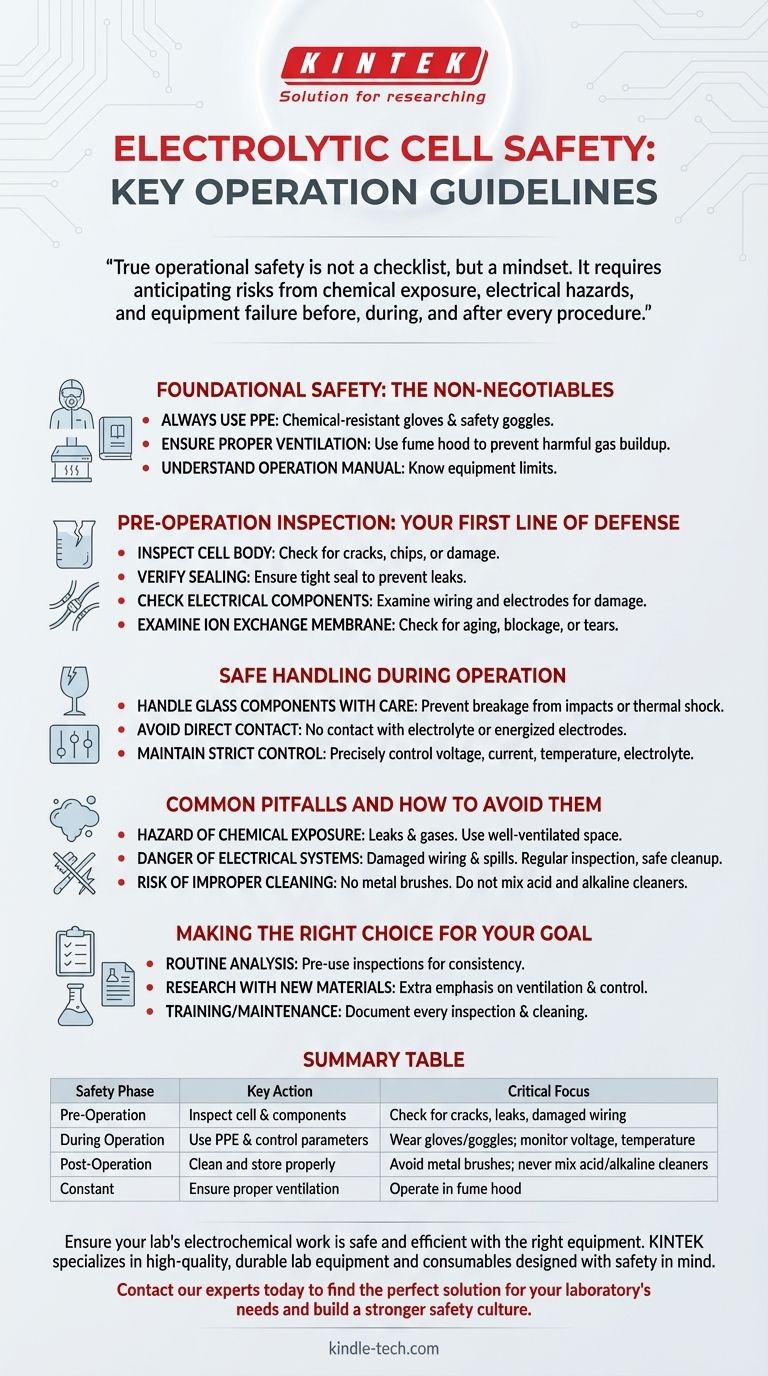

Foundational Safety: The Non-Negotiables

Before any experiment begins, certain baseline precautions must be in place. These practices form the foundation of a safe laboratory environment and are not optional.

Always Use Personal Protective Equipment (PPE)

You must always wear appropriate protection. This includes chemical-resistant gloves and safety goggles, especially when handling corrosive electrolytes or the cell's electrodes.

Ensure Proper Ventilation

The electrolysis process can generate harmful gases or high temperatures. Operating the cell in a well-ventilated area, such as under a fume hood, is essential to prevent the buildup of toxic or flammable vapors.

Understand the Operation Manual

Before use, you must be thoroughly familiar with the device's operation manual and all associated safety guidelines. Understanding the specific design and limits of your equipment is a critical first step.

Pre-Operation Inspection: Your First Line of Defense

A rigorous inspection before powering on the equipment is the most effective way to prevent accidents. It allows you to identify potential failures before they occur.

Inspect the Cell Body for Integrity

The cell body is often made of glass and is fragile. Carefully inspect it for any cracks, chips, or damage that could compromise its structural integrity.

Verify Sealing to Prevent Leaks

Ensure the cell lid and all fittings create a tight seal. Electrolyte leakage can corrupt experimental results, create a chemical hazard, and pose a risk of electric shock.

Check Electrical Components and Wiring

Examine all wiring for signs of aging, fraying, or damage. Check the electrodes for signs of excessive corrosion or physical damage that could affect performance and safety.

Examine the Ion Exchange Membrane

If your cell uses one, inspect the ion exchange membrane for aging, blockage, or physical tears. A compromised membrane can lead to process failure and potential hazards.

Safe Handling During Operation

Once the experiment is running, safe practices must be maintained to manage the active chemical and electrical processes.

Handle Glass Components with Care

Always handle the cell gently to prevent breakage. Sudden impacts or thermal shock can cause the glass to shatter, leading to spills and potential injury.

Avoid Direct Contact

Never make direct physical contact with the electrolyte or the energized electrodes during operation. This is critical to prevent chemical burns, poisoning, and severe electric shock.

Maintain Strict Control Over Parameters

Precisely control experimental parameters such as voltage, current, temperature, and electrolyte concentration. Abrupt or uncontrolled changes can lead to unexpected reactions and unsafe conditions.

Common Pitfalls and How to Avoid Them

Understanding the most common failure points allows you to address them proactively. Ignoring these risks is the primary cause of accidents.

The Hazard of Chemical Exposure

Leaks and gas production are the main vectors for chemical exposure. A pre-operation seal check and constant operation in a well-ventilated space are your primary defenses.

The Danger of Electrical Systems

Damaged wiring and electrolyte spills create significant shock hazards. Regular electrical inspection and immediate, safe cleanup of any spills are non-negotiable.

The Risk of Improper Cleaning

Never use metal brushes to clean the cell, as they can scratch the surfaces. Critically, do not mix acid and alkaline cleaning agents, which can cause a violent exothermic reaction.

Making the Right Choice for Your Goal

Your specific objective influences which safety protocols require the most attention.

- If your primary focus is routine analysis: Make pre-use inspections for leaks and damage your unwavering habit to ensure consistent and safe results.

- If your primary focus is research with new materials: Place extra emphasis on ventilation and parameter control, as reactions may be unpredictable.

- If your primary focus is training or maintenance: Document every inspection and cleaning procedure to build a reliable history and a strong safety culture.

A disciplined, proactive approach to safety is the foundation of all successful electrochemical work.

Summary Table:

| Safety Phase | Key Action | Critical Focus |

|---|---|---|

| Pre-Operation | Inspect cell & components | Check for cracks, leaks, and damaged wiring |

| During Operation | Use PPE & control parameters | Wear gloves/goggles; monitor voltage, temperature |

| Post-Operation | Clean and store properly | Avoid metal brushes; never mix acid/alkaline cleaners |

| Constant | Ensure proper ventilation | Operate in a fume hood to mitigate toxic gases |

Ensure your lab's electrochemical work is safe and efficient with the right equipment. KINTEK specializes in high-quality, durable lab equipment and consumables designed with safety in mind. Whether you need reliable electrolytic cells or other laboratory essentials, our products help you maintain the highest safety standards. Contact our experts today to find the perfect solution for your laboratory's needs and build a stronger safety culture.

Visual Guide

Related Products

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Electrolytic Electrochemical Cell for Coating Evaluation

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

People Also Ask

- What is an electrolysis cell also known as? Understanding Electrolytic vs. Galvanic Cells

- What handling precautions should be taken when storing an all-PTFE electrolytic cell? Prevent Permanent Deformation

- How should the electrolyte be managed as part of maintenance? A Proactive Guide to System Longevity

- What precautions should be taken to protect the quartz window of the electrolytic cell? Ensure Accurate Spectroelectrochemical Data

- What are the guidelines for sterilizing the electrolytic cell? Ensure Sterile, Damage-Free Lab Results

- How should the H-type electrolytic cell be connected? Expert Setup Guide for Precise Electrochemical Experiments

- What are the advantages of using quartz glass as the material for an electrocatalytic oxidation reactor cell?

- What role does an electrochemical workstation play in TiNO coating evaluation? Quantify Biological Corrosion Protection